Diving into Minutia, an MDF treatise (of sorts). Super-Nerd card required.

The following is my pseudo-scientific research into two premium MDF products. Ranger Board and Medex. My methodology is probably questionable and controls somewhat variable. Me and MDF and the tools at my disposal.

Before I start; Yes, I have a life. Yes, it may be hair-splitting. I’m curious to a fault and I indulge it…sue me.

ObservationsAppearance:

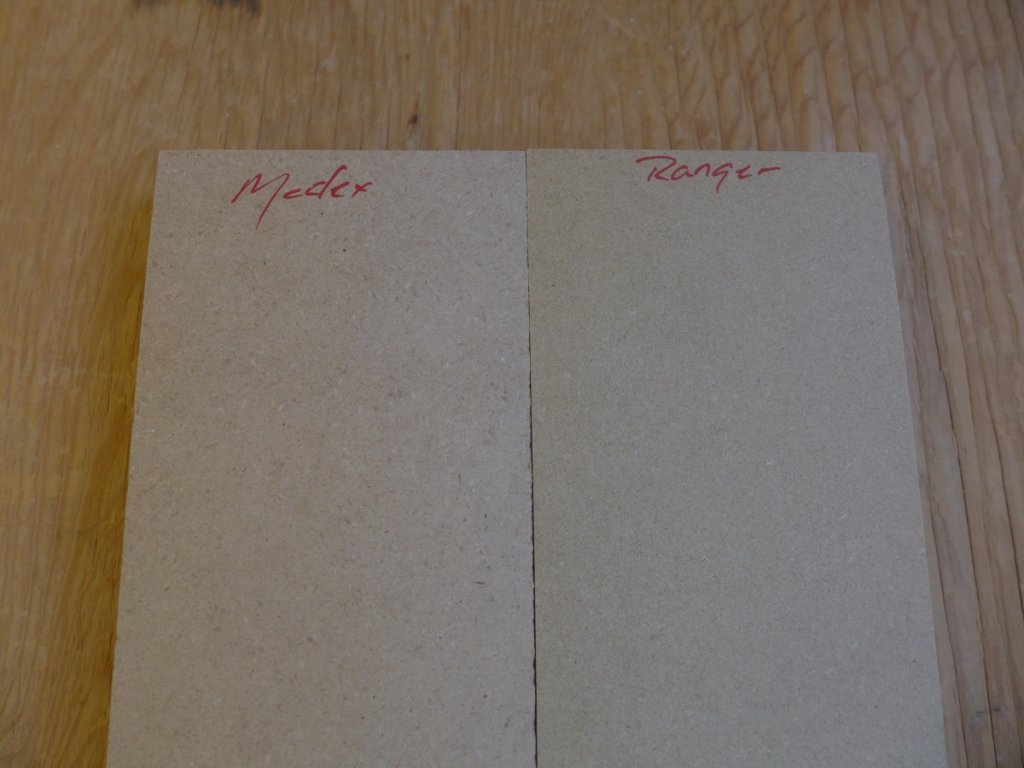

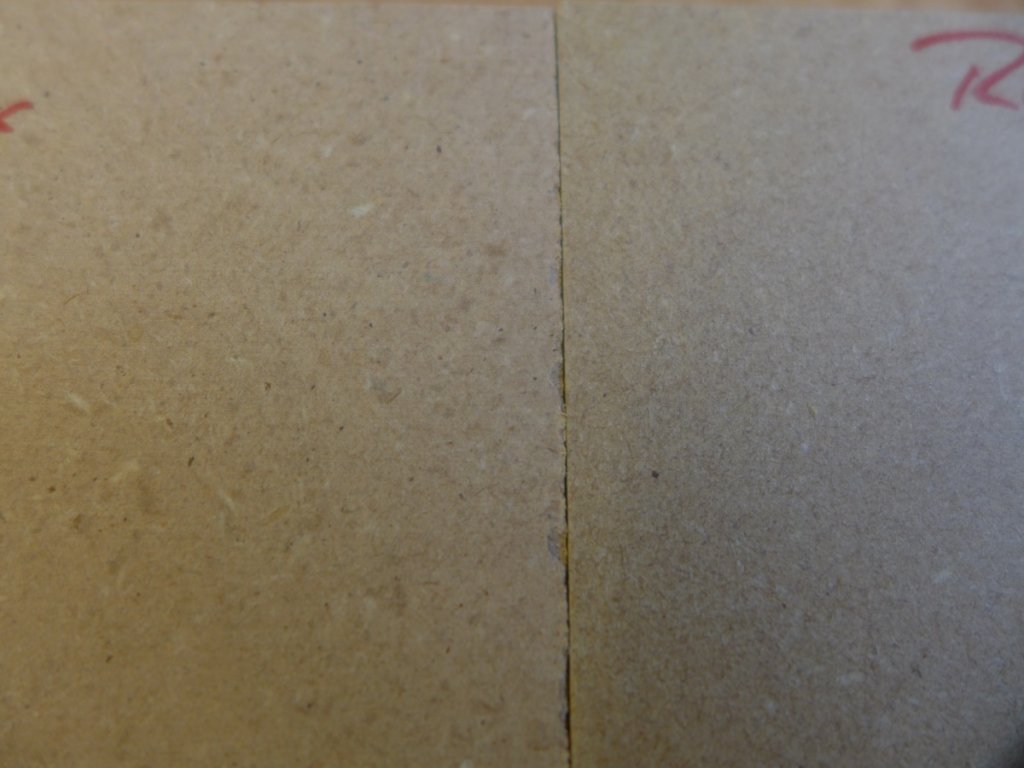

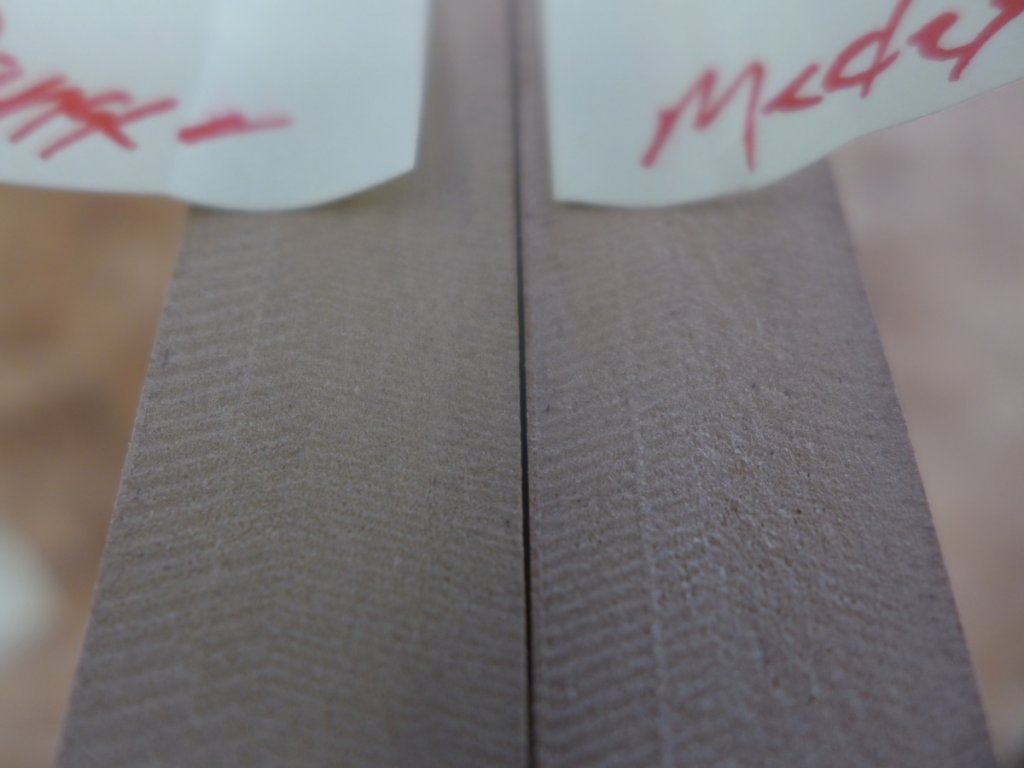

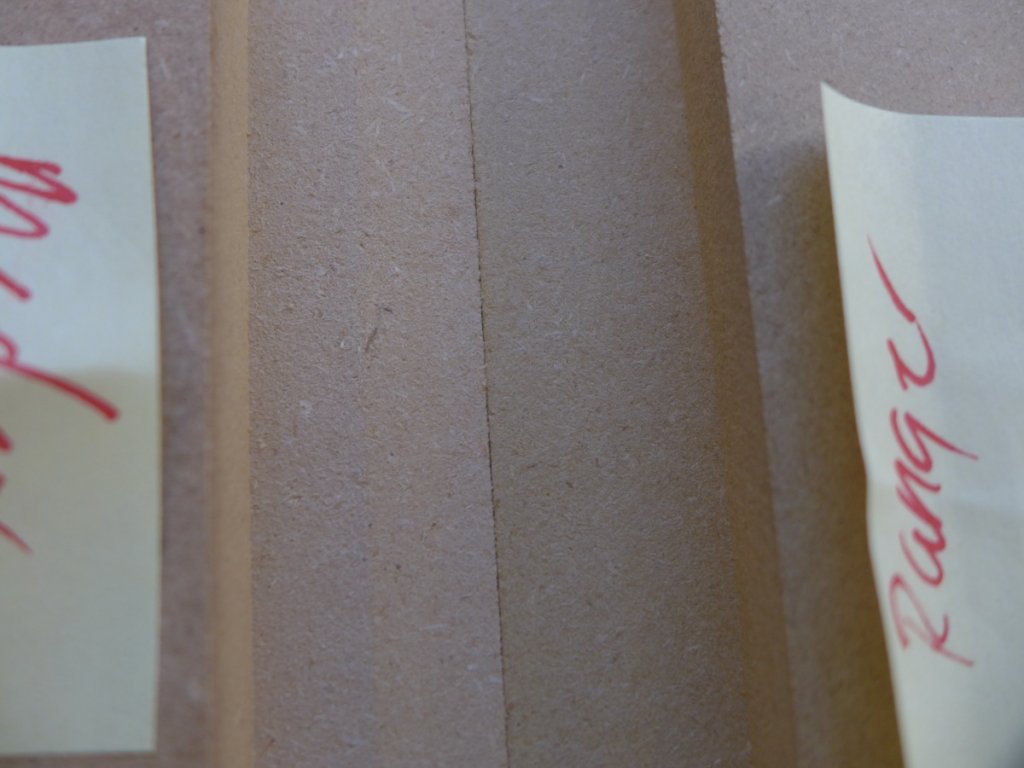

Both look like MDF. I didn’t taste them. The Medex looks slightly more granular, but I might attribute that to differing color of particles. Whereas the Ranger Board looks finer and more homogenous in color. If forced to choose which looked more attractive, I’d have to give the nod to Medex. Its warm brownish tone ultimately more appealing than the yellowish pallor of Ranger Board. The Medex has a more prominent “grain” on surface. I assume from sanding at factory.

Cutting:

Both can be cut with conventional woodworking power tools. I didn’t try an adze or handsaw. Machining the Medex on CNC router produced larger, more defined chips with less apparent dust. Ranger Board was less chips and more dust. This would lead me to conclude that the Medex is more “plastic” by some margin. I attribute this to either the glue used, the actual wood in its make up or some combination of those. Ranger Board makes some claim about particular wood(s) involved in manufacturing, but I can’t be sure of the relevance to the real world, save the appearance.

Moisture resistance:

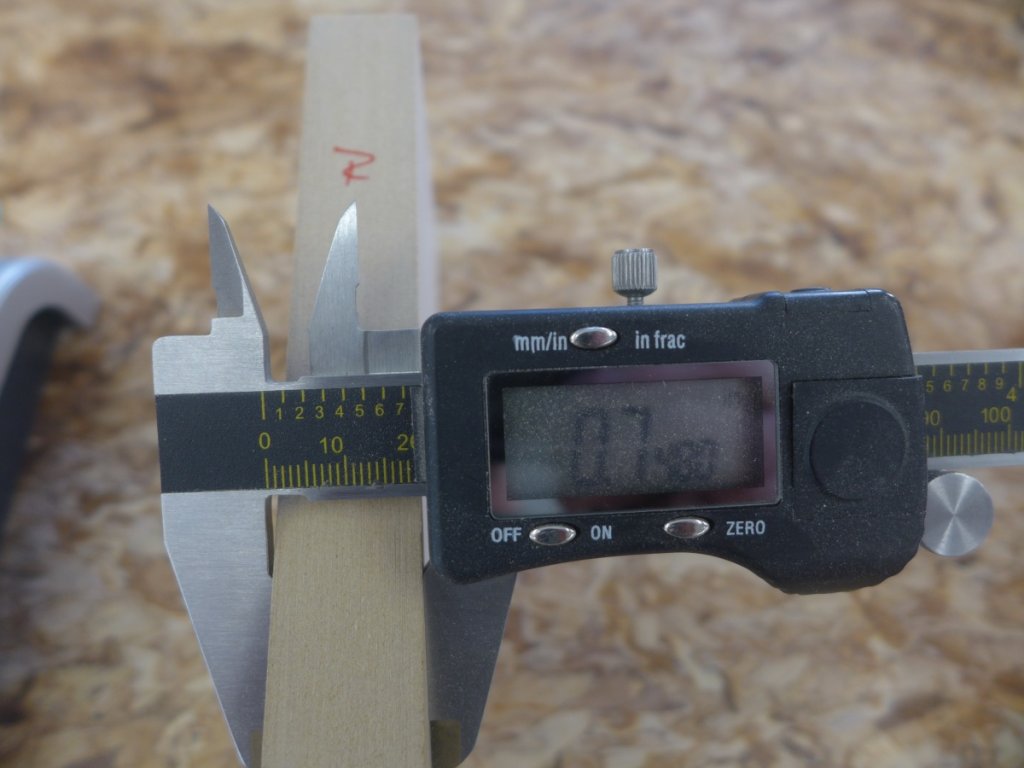

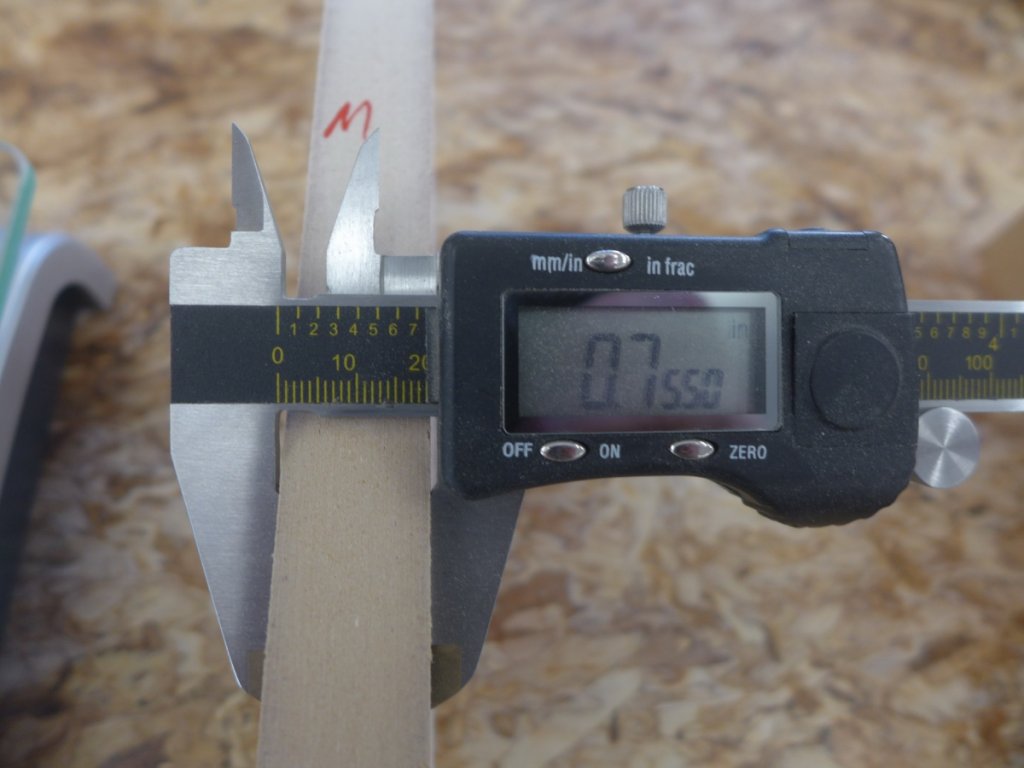

This required that I break out the “big gun” tools. A three gallon bucket and an inexpensive Chinese micrometer. I dunked the samples in tap water for 30 seconds, measuring thickness both before and after. I did let them dry before re-measuring while I mowed the lawn. No appreciable difference between the two. The differences in measurements could easily be attributed to ho-hum tools or methodology. The surfaces of both were slightly rougher to the touch after the dunking and drying.

Stability after machining:

I qualify “after machining” because both were (pretty darn) flat to begin with and held flat via some serious vacuum during machining. Thus I attribute the before to after cutting variance to some sort of internal stress relief. Perhaps supernatural in nature. While the Ranger Board remained mostly flat, the Medex showed some bowing on the more aggressively machined parts. Probably no concern in the speaker building realm as it could easily be removed when clamping assemblies.

Where does this leave us (me)?

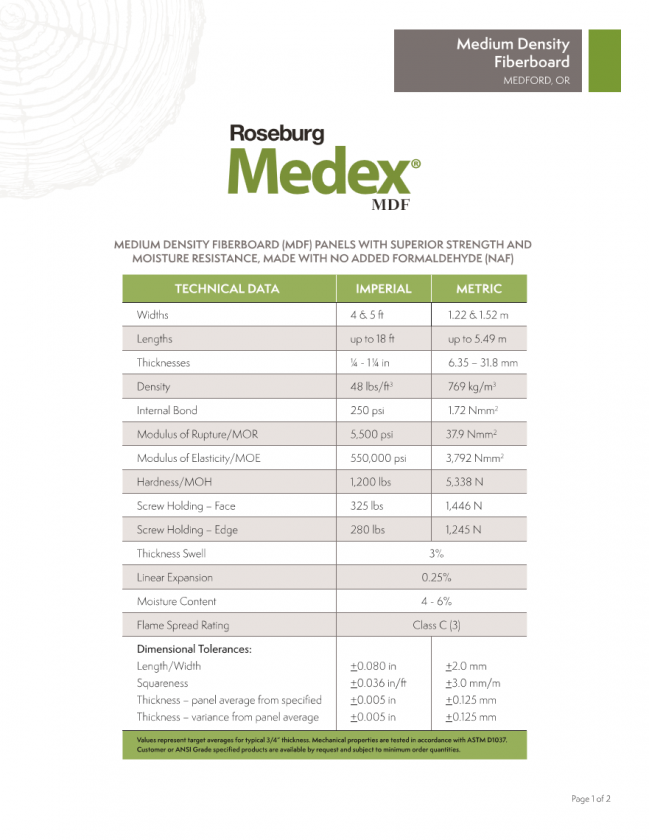

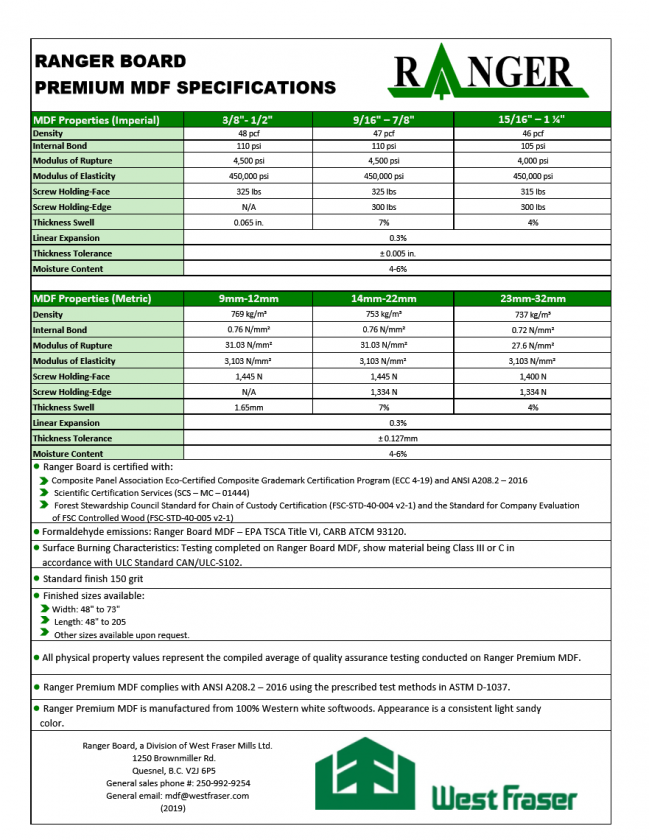

Based on weight and dimension measurements and keen observation through my magnifying safety glasses, I would conclude that either is superior to mill run MDF in terms of speaker building. That density being the key ingredient to a few things: Holding a crisp edge when machining, resistance to impact damage and, of course, lack of sonic contribution. No clear winner here from my point of view in spite of manufacturers’ claims. They aim at slightly different markets with their hyperbole. Ranger Board guns for the cabinet door world, and Medex touts its moisture resistance. For intents and purposes in the speaker building world I’m not sure either has any real value. Their specification sheets seem to show some numbers that would give the nod to Medex. More is better, right? I just can’t say with any certainty that modulus of elasticity or internal bond strength is relevant in the speaker building arena.

For what it’s worth, I would and will use either with confidence.

Peter Rawlings SOPE-LMN

School of Hard Knocks magna cum laude

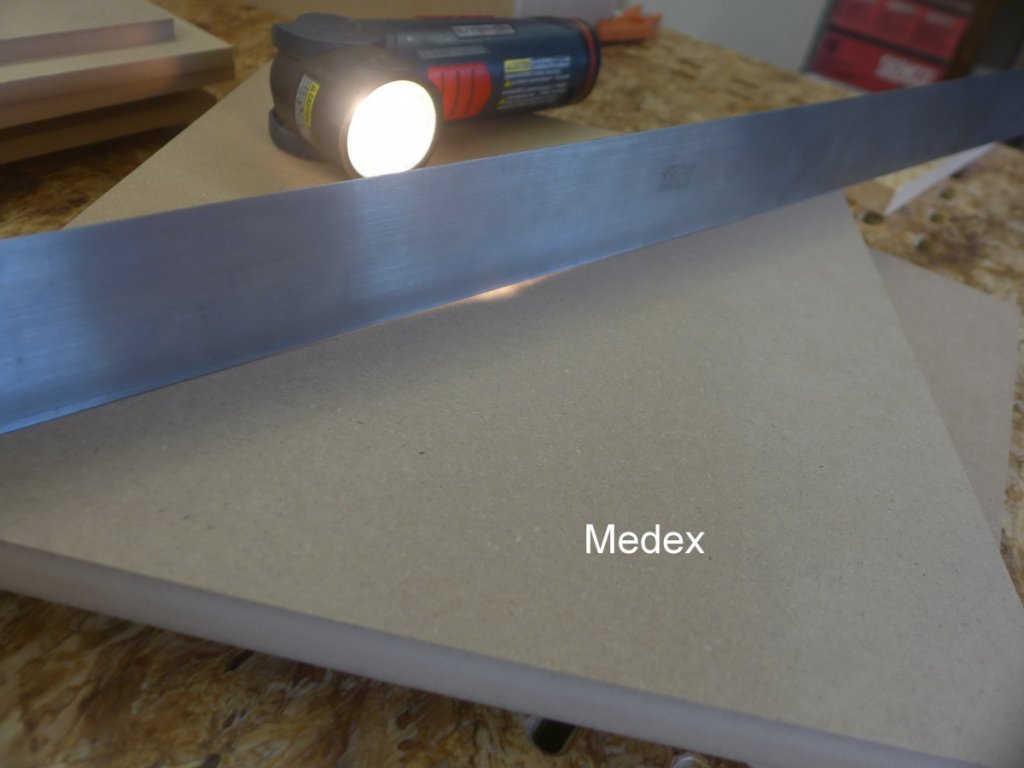

What they look like:

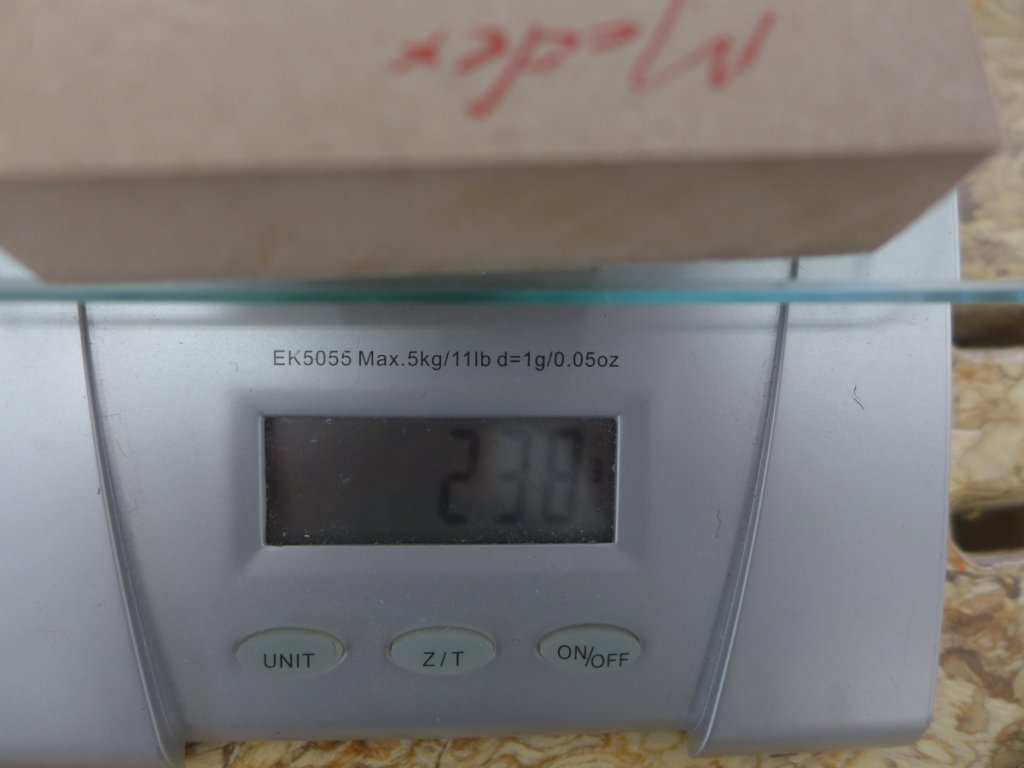

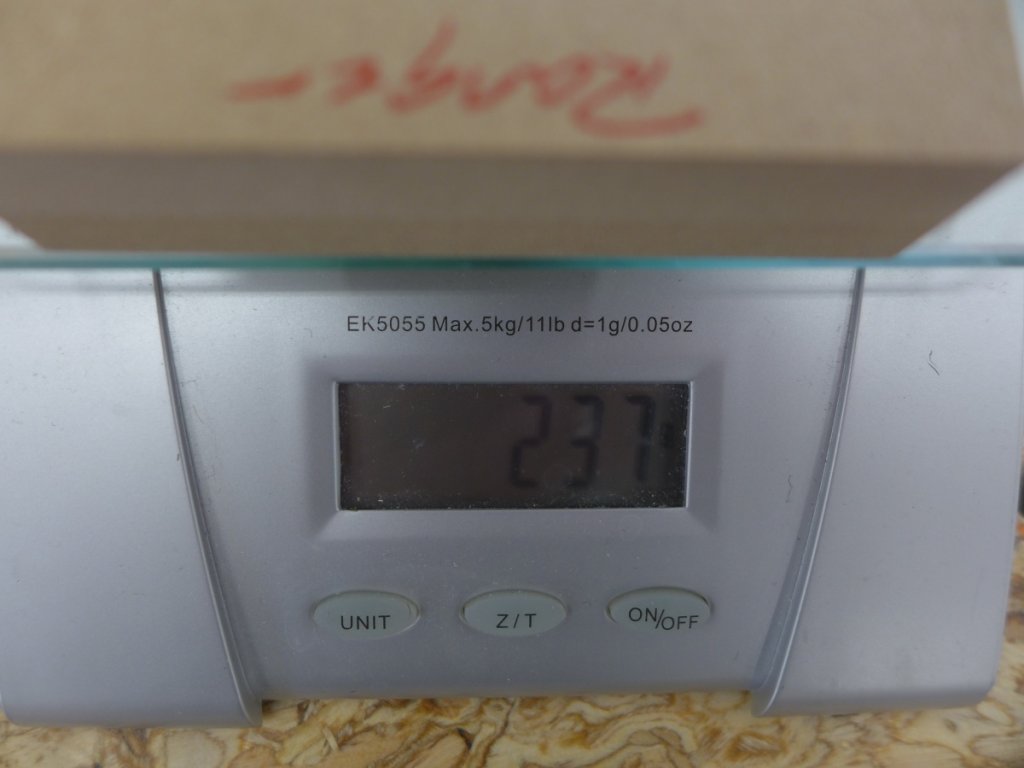

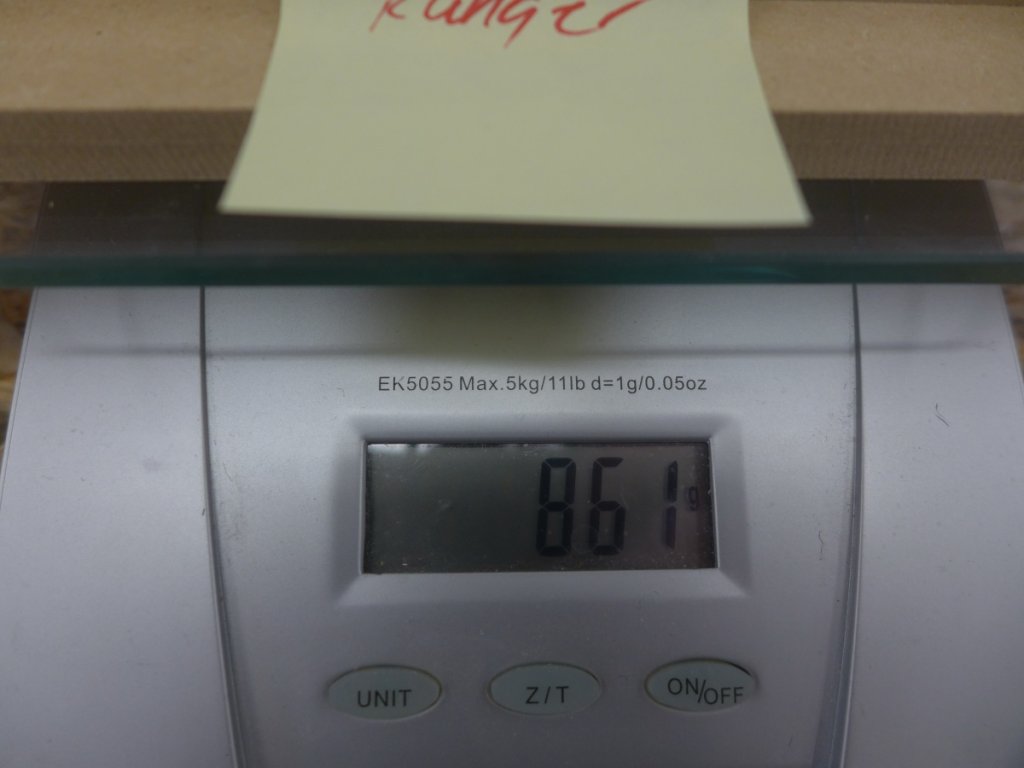

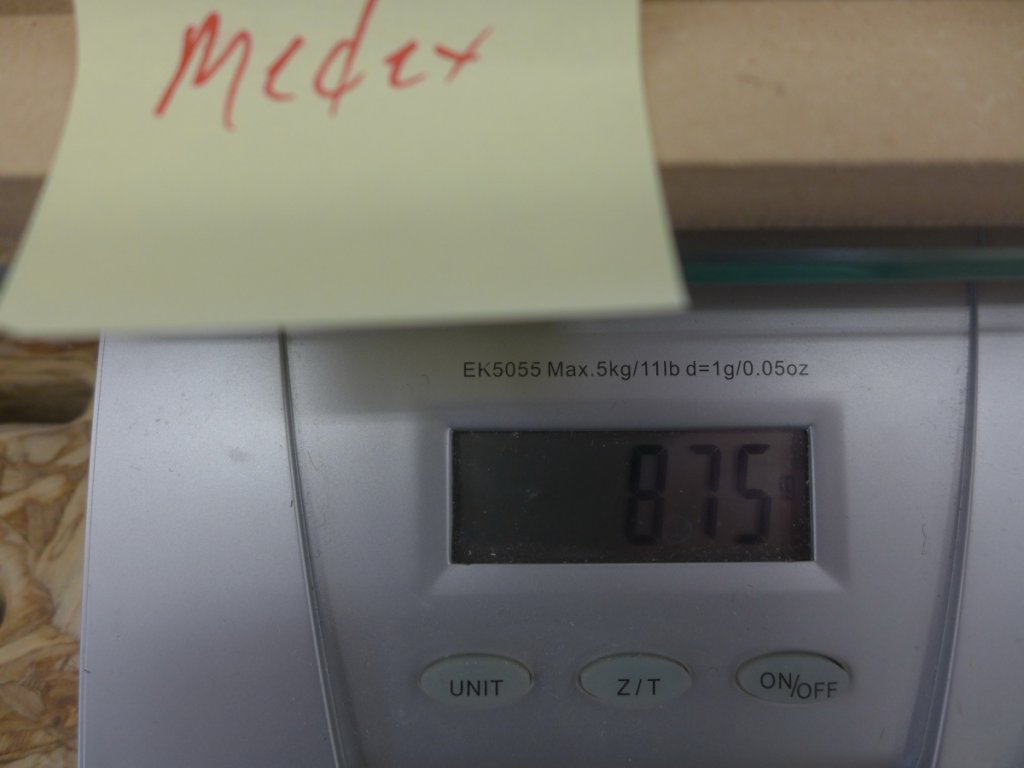

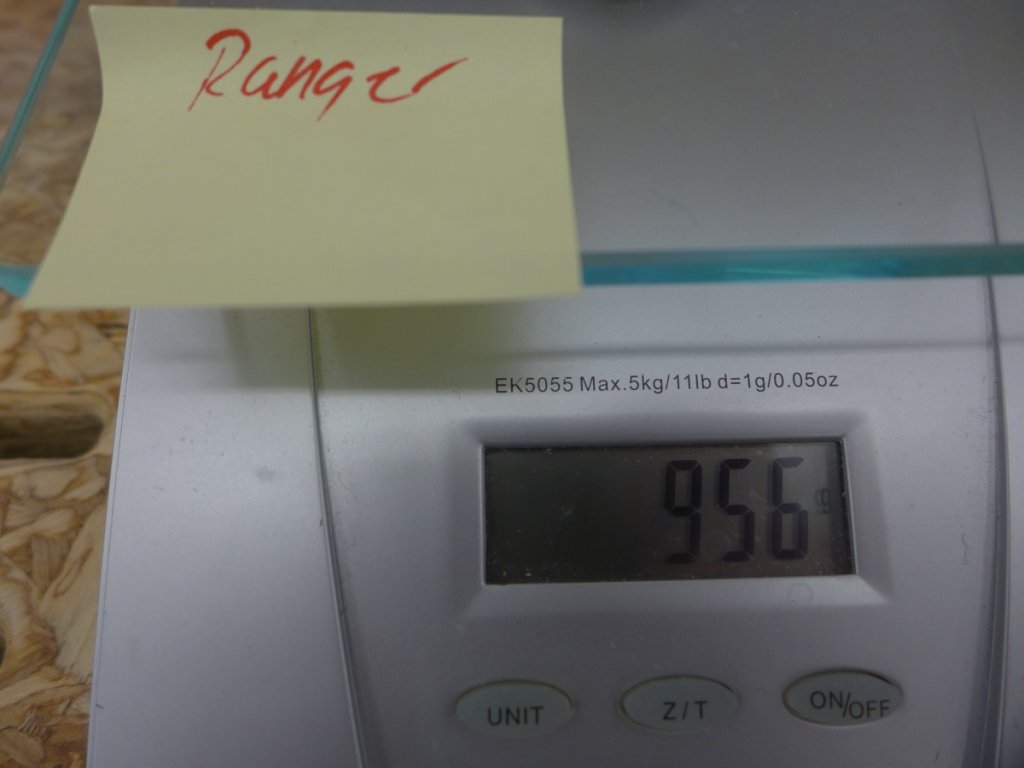

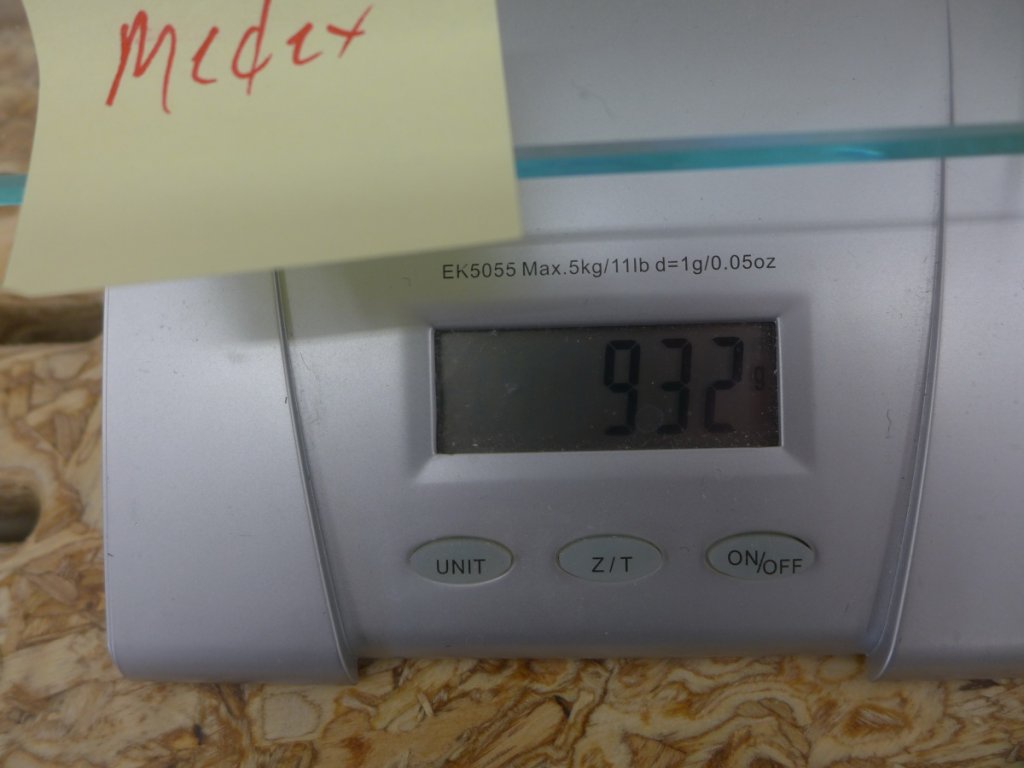

Sample weights:

Baffle weights

Top/Bottom weights

Back weights

Thickness before dunk (BD)

Thickness after dunk (AD)

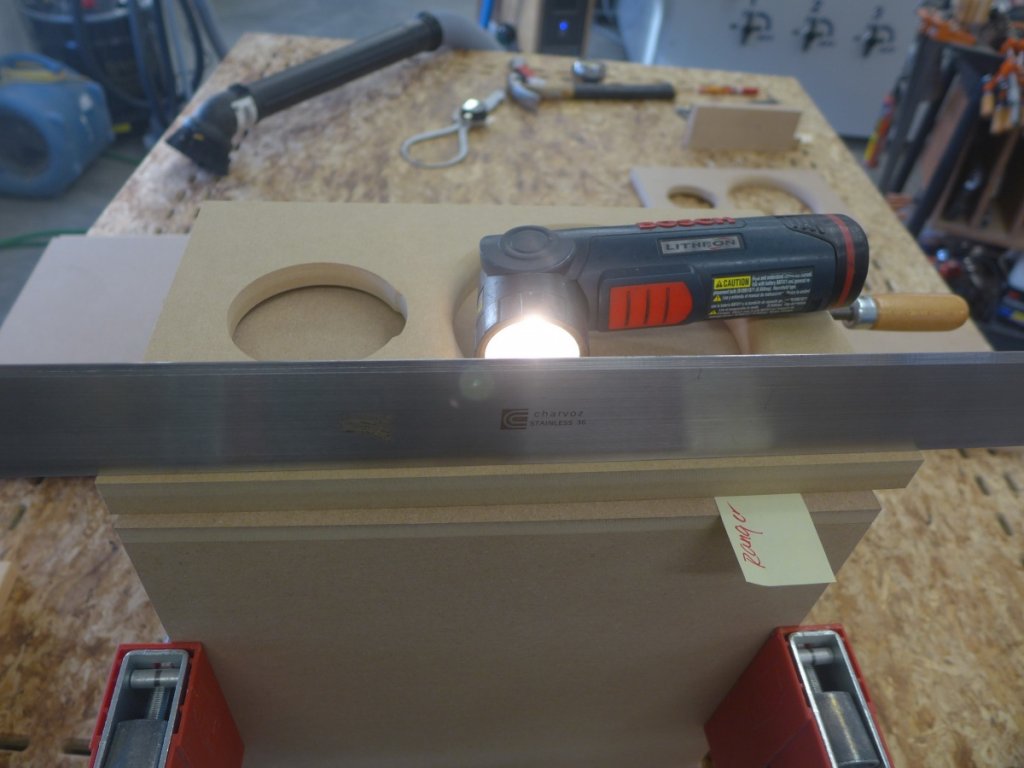

Flatness (not sharpness)