Hello,

Figured I would join the crowd and show off my recently finished build of the Hypex NCore amps. I decided to build 2 X Dual Mono amps. I have seemed to run into an issue with one of the NC400 modules which will most likely require an RMA replacement and annoyingly delay my plans on running a quad amp setup on my B&W's but at least I have one Dual Mono to keep me occupied for now.

So far, sound quality is very impressive on there NCore's. My previous amp was a Pass Labs X250 so I am using that as my point of reference for comparison and thus far the NCore's are holding their own nicely. I feel its too soon yet to say which one I think sounds better but the fact that I am not immediately missing the SQ I was accustom to while using the Pass amp certainly speaks volumes to the NCore's potential as they break-in.

Now onto the build process:

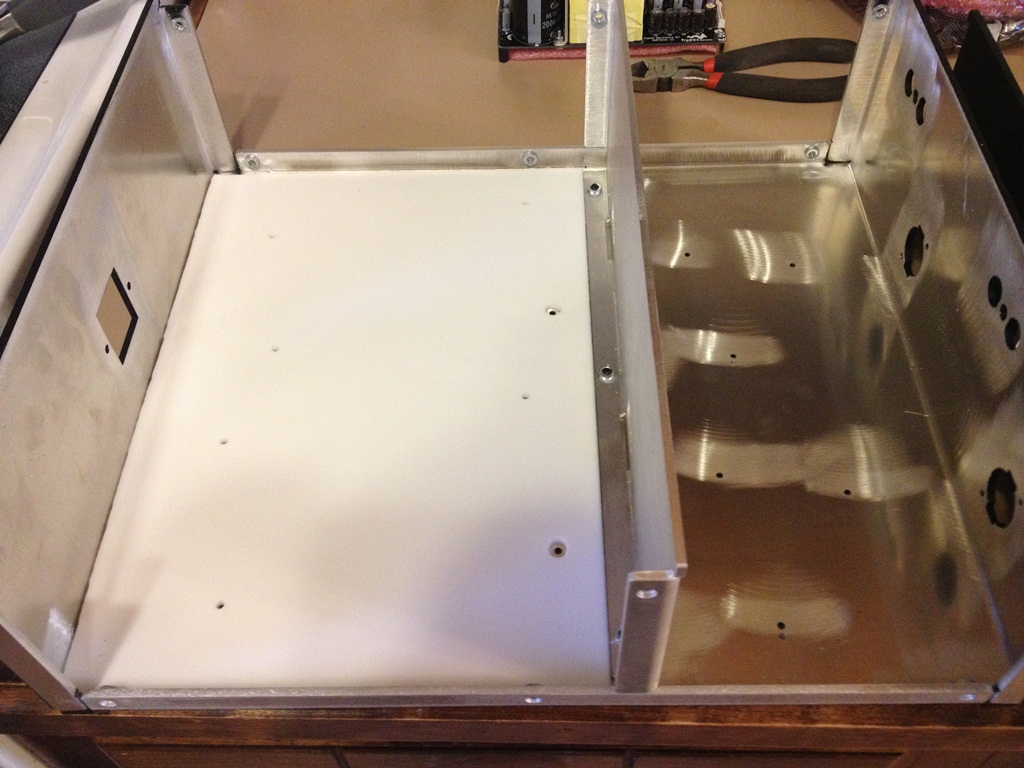

Sizing up the 3mm thick Teflon sheet inside the chassis which will live under the SMPS600's. I choose to add this layer of Teflon for a few different reasons. One was in case I wanted to "Unearth" the chassis. Second, was to added additional dampening between the chassis base and the SMPS600. The aluminum chassis had some ringing properties to it when rapped with a knuckle which I wanted to minimize. Don't want that propagating into the signal chain. Lastly, It should help eliminate any stray voltages to the chassis, if they exist, by way of the SMPS.

7 X stacked SS washers to maintain contact between the metal standoff foot and the chassis.

Seeing double! The build is progressing nicely

All wiring is complete. Much time and effort was taken to ensure both chassis's wiring is layed out and positioned in the same mannor as best as possible.

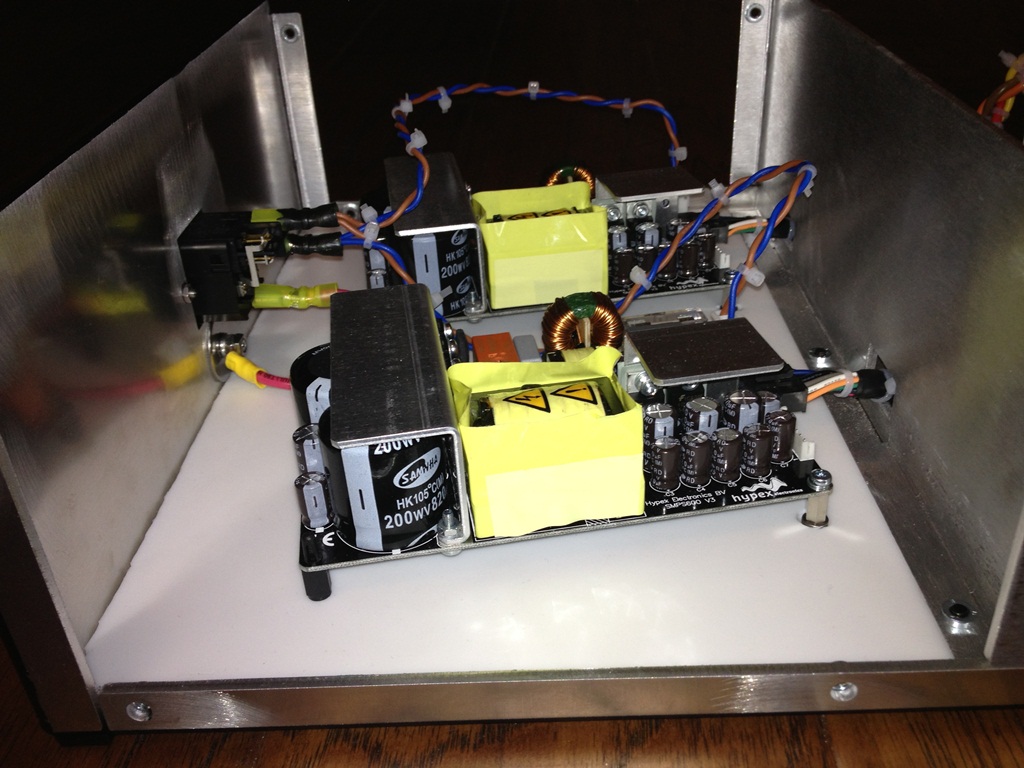

SMPS600's ready for action

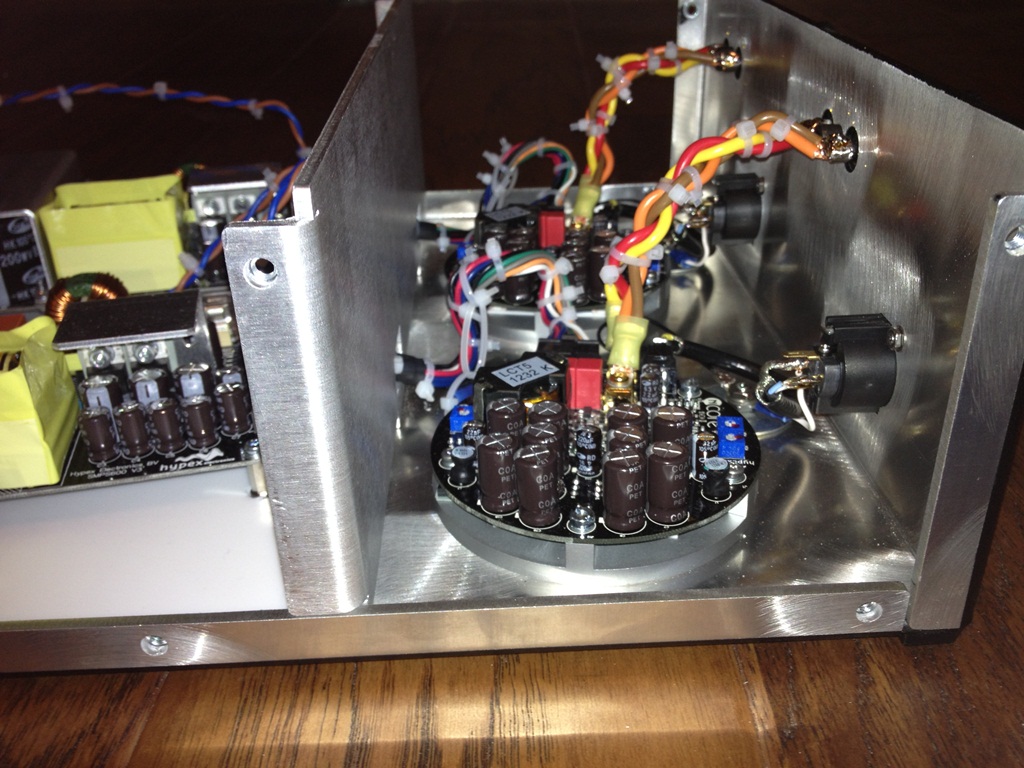

NC400's ready for action. I used dual runs of 14ga Mogami 2921 to each binding post...

I will also be using short 2ft runs of Mogami 2921 from the back of the amp to each speaker's dual binding posts. This allows me to maintain the same gauge and wire type from wafer board to speaker. I'm in no rush to attempt to wire this up again anytime soon

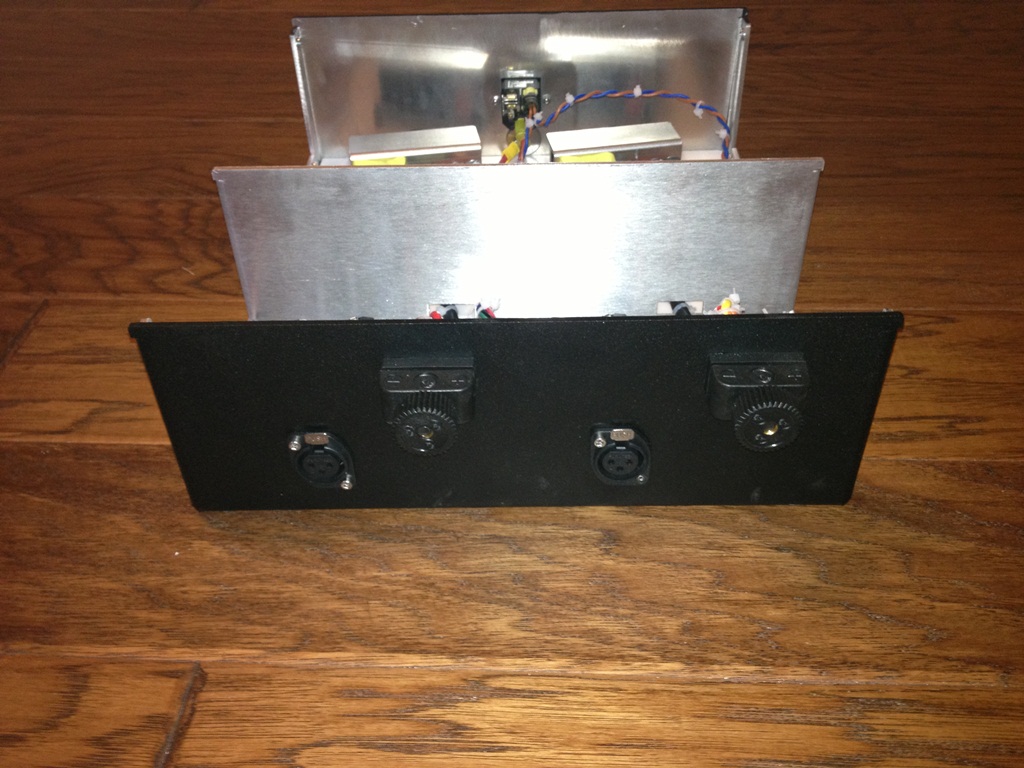

Furutech FT86F & Cardas Binding Posts. If I had to do this over again I think I would opt to not use the Furutech XLR's since their body is made of plastic and they were very difficult to get the cutouts correct for since they are not the standard shape. In addition, after inserting them into the holes the metal clips which are used to release the XLR cable seem to stay pressed in and require a long finger nail to pull them back out into their original starting position.

The Cardas posts are very sweet but again I question weather the effort involved in getting those holes correct was worth it or not. Ignoring the odd shaped holes, the concept of how they work was very slick allowing you to fully pack the inside posts with wire to achieve a very direct connection with the spades on the outside of the chassis. They are also extremely solid once mounted on the chassis.

Schurter DC11 - 15amp IEC Input with Power Switch

Chassis fully assembled with top cover in place. I designed the chassis myself using a CAD tool provided by the company who did the metal work. I can highly recommend them based on my experience during this build. See them here:

http://www.protocase.com/Another point of note if I had to do this again would be to place some cutouts above the NC400 modules as these seem to generate more heat then the SMPS600 do. I have been keeping an eye on the temps of the modules using my laser thermometer over the last day or so. With the chassis cover in place things seem to be fine even though there are no holes above the NC400 chamber.

Strategically placed "N" on each side the chassis to make it easier to tell what's going on inside. Plus it looks cool at night

The wooden spoon is taking the place of my finger when powering on the chassis..

Haven't figured out the best way to test if it's live or not yet so the spoon will work for now.

Herbies stabilizer on top to minimize top cover vibrations & Cardas Myrtle wood blocks for feet.

Shot from back of the speaker where I plan to place each of the amplifiers. There will be one Dual-Mono amp per speaker with 1 x NC400 & 1 x SMPS600 powering each half of each channel. From here you can see the reasoning behind why I have the IEC power plug coming out of the other side of the chassis as it allows me to use short 2ft speaker cables like the owners who have a single mono build and also provides a straight shot from the IEC power cable into the dedicated wall outlets centrally located between both speakers.

The brains of the operation. I reluctantly had to replace my Ayre Preamp & QB9 DAC in order to run multiple Ncore amplifiers. So far, the Classe doesn't seem to be taking a back seat to the Ayre while allowing for a whole host of other added features.