KTS thank you very much for that! I'm hoping this lengthy journey will help others!

BIG Update!I've made what now feels like pretty significant progress! Let's get started with some photos!

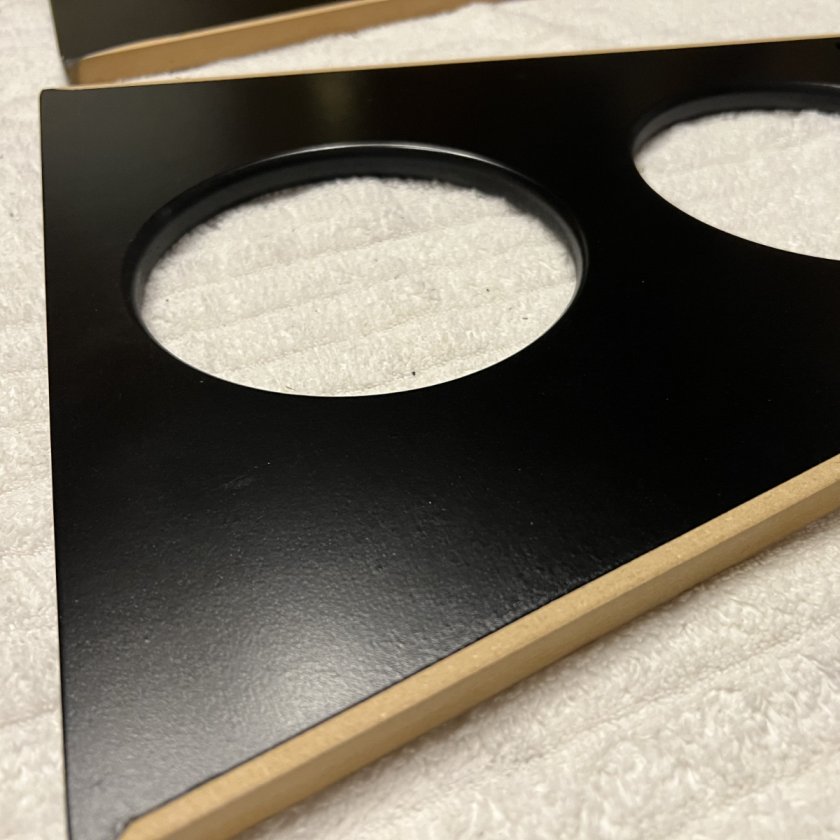

Last images I posted were of the veneer applied to the speaker sides. This time, I've got them routed out!

Here's a closeup of the cutout for open side next to the tweeter...to run your finger along the edge, you wouldn't know the veneer wasn't originally a part of the MDF! I used a Milwaukee trim router with a spiral down flush trim bit. I think I'd mentioned previously that I'm using the Heat-Lock glue from veneersupplies.com and that stuff is absolutely amazing.

After I got done with that, I realized I still had a little bit of sanding to do. Using 80 grit sandpaper, I "gently" sanded the back of the MDF where the NoRez will be installed, and I attempted to sand off a decent amount of the spray paint on the back beveled parts of the baffle that will be glued to the sides.

Then, I needed to move on to removing the masking tape I put on all the bracing I painted to ensure there would be good surfaces for the wood glue to adhere to when it was all installed. Notice that I masked all he edges EXCEPT the "wide" part of the braces as those will be visible from the back of the speaker.

Here's a couple of them after I removed the painters tape - the tape came off pretty easily even though it was a bit tedious. I just made sure I pulled away from the paint and not down towards it, just in case the paint would try to lift off with the tape (anyone who's painted latex paint on a wall and left painters tape on too long will know what I'm talking about). Fortunately it never felt like it was going to try and lift the spray paint from the MDF.

I also wanted to show a closeup of the painted brace - keep in mind that ALL the bracing and anything that wasn't the front of the baffles I used pretty inexpensive Rustoleum paint for the finish. Considering I didn't spend a crazy amount of time trying to make these perfect, I am very impressed with how they turned out.

A couple of notes on the Rustoleum vs SprayMax and why choose one or the other and if it even matters...

I chose to use the Rustoleum on the parts that would rarely be touched or seen for two reasons

1. Rustoleum was about $6/can whereas the SprayMax was about $30/can (and they both have similar coverage)

2. Rustoleum is not nearly as scratch / scuff resistant as the SprayMax

Because those parts were never going to be touched, I figured putting a cheaper/less durable finish on those was perfectly fine.

What I will say is this - the Rustoleum painted pieces do look very nice. Considering I didn't spend near as much time prepping the surfaces of the braces compared to the baffles, I am very impressed with the outcome. That said, the Rustoleum sprays SOOOOO very differently than the SprayMax. The Rustoleum paints need to be sprayed in very thin layers using very fast motions to avoid runs. When I post the videos of spraying with the SprayMax, you'll see I sprayed smoothly - not too fast or too slow and I continued layering until I reached the thickness I desired before moving on. So there are VERY different techniques to spraying the two paints in order to get the results you'd want.

And finally....how about some pictures of what it looks like put together?!

First is a shot where I just started dry-fitting the pieces. I followed the directions posted by Jay (CaptainHemo) on this thread - if you follow those directions to a T, it's nearly impossible to mess up...

https://www.audiocircle.com/index.php?topic=169138.msg1792762#msg1792762I used some paper towels on the veneer surface to keep the clamp from marring the surface up, and I just put three of those on the baffle-to-side to keep things in place.

After that, I just continued to drop pieces in place, tap things around to where the BACK of the braces lined up smoothly with the back of the side dados, and then I dropped the other side of the speaker on top and just tapped it into place. The fit of everything is pretty amazing. It all fits together perfectly/snuggly! So here's a shot of it all dry fit together!

Today I went and picked up some TiteBond III as it has the longest "working time". I already had some TiteBond I & II but after reading several threads, it feels like having more working time is better. Also, the only reason I didn't start gluing tonight is I have some silicone glue brushes arriving tomorrow to help me spread the glue evenly and reduce any squeeze out.

When I go to do the glue-up (hopefully tomorrow night), I'll be placing some painters tape over the veneer to make sure none gets on the surface of that. I'm not too worried about the painted baffle as it should be easy to wipe off....but maybe...just maybe I should put some painters tape on there too just to make life easier.

Due to the space and number of clamps needed, when I go to do this it'll be one speaker at a time. So it'll likely end up being a two to three day process overall.

I've also been researching the best finishing for the veneer and I've found some pretty cool information I'll share in a post when I get to doing that. Pretty excited about what's coming. I really do think these things are going to look killer when they're all done!