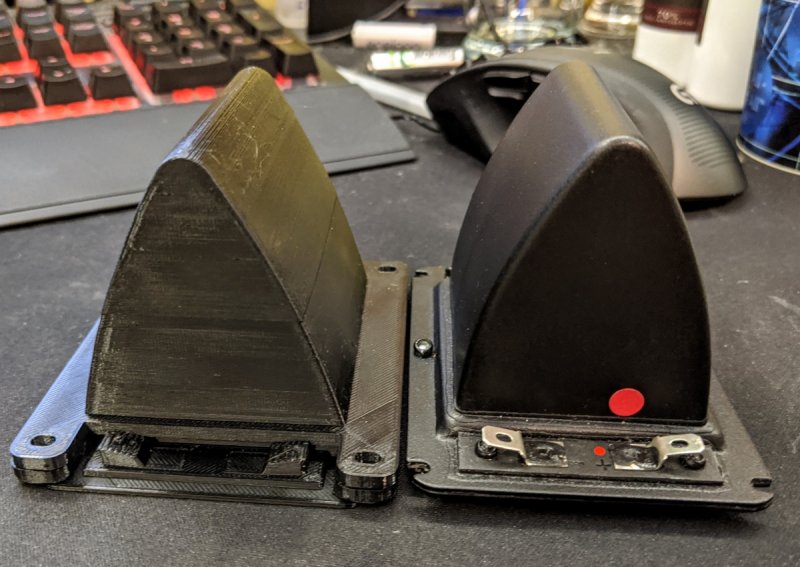

Okay, I got my 3D printed cups & bars in the mail today! I also went ahead a ripped off the original back cup, & I'm happy to say they fit really nicely, a little tight, but within tolerances.

Rear face with spacer and hand cut rubber gasket.

A silicon sealant should work well too:

The curved walls in the stock cup are doubled from the base to the first inch. The felt stuffing is glued in and incredibly soft. Not far off from the feeling of cotton balls, and should make for a fair substitute within the custom cups. It is also glued into place, so i imagine any cotton balls used probably should be glued into place as well.

The printed cup is pretty resonant, so lining the inside with a dense product like butyl based liners, or no-rez on the outside surfaces is probably a good idea.

If/when I make any further adjustments/prototypes, I'll probably use thicker walls to reduce the structural resonance, but will probably still recommend such a lining, unless using a dense glue with the cotton that can achieve a similar effect.

Now for the face plate rods:

They aren't quite as smooth as i hoped they'd be, but i imagine some coats of paint and a some gentle sanding should help smoothen them out. Tho I think I also want to make variants that are taller with a gentle curve until it gets close to the tip, I suspect it might be more beneficial to the response than just a simple half-circle option. With a waveguide or faceplate, only 3 rods are needed per Neo tweeter.