The Wedge is an incredible speaker and deserves a beautiful enclosure. But the Wedge flat pack supplied really only can be painted and I am

a woodworker not a painter. Thus the only solution is to scratch build a Wedge later in a way that uses veneer. Since the waveguide on the Wedge needs

to be painted, I thought something like these Chario speakers would look good and I think I can handle the painted sections.

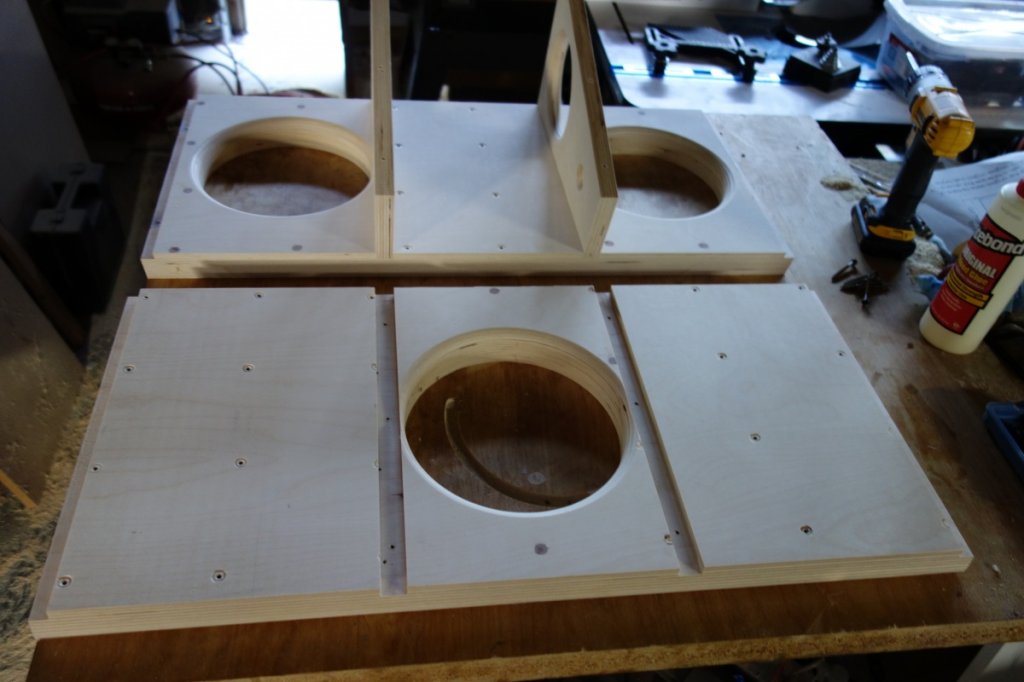

I am going to start the Wedge Base first. It is made from Baltic Birch, it was free thanks to the forklift operator who dropped a unit at work.

The sheets were laminated together using Kreg screws, then they were cut to size, dadoed and the hole cut. If you like rounders on your work, it is much

easier to put a roundover on one edge before you cut the bevel on the side. Then cut the bevel up to the low edge to the roundover and when you turn your

piece over to cut the other bevel, the roundover will rest against the fence instead of a sharp corner trying to go under the fence.

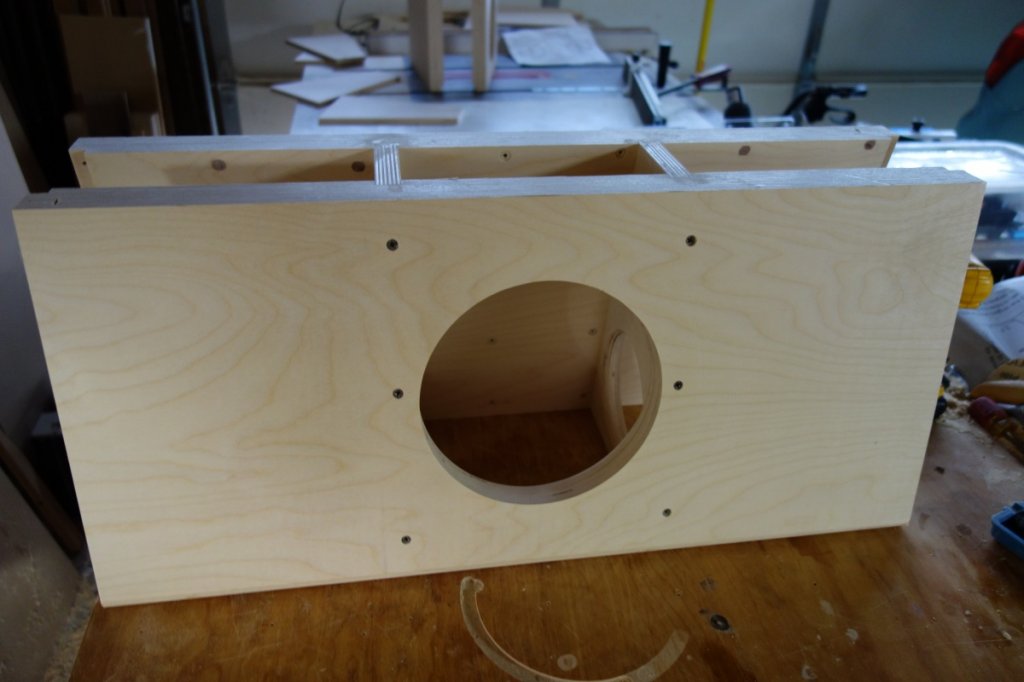

Mike was concerned that a dado would interfere with the roundover. This is what it looks like.

Sides were screwed together since I am using veneer. Much easier than clamps and anyone that has not built a box with dadoes

as opposed to butt joints needs to feel how much stronger a box built with dadoes is.

Only 3 clamps needed for this build. Used the cutoffs from the braces. I was going to use band clamps put they were all tangled up.

I will be using 17" x 30" sheets of raw veneer so I cut 1-1/4" strips and put a 1" roundover on them and the nailed them to the front.

That leaves a 1/4" lip on the front so that a 3-1/4" painted piece can be installed later, after the cabinet is veneered and finished.