Is the use of the fiberglass packing around the port tubes offer any positive dampening if using a good sidewall stick on absorber? I used No-Rez throughout, and am wondering of the need to also use the fiberglass in the woofer enclosure like you have. As for outside finishes, it is the owners choice, but these baby's warrant something that does them justice. I finished mine in South American Premium Rosewood 22ml veneer - not cheap or easy to finish, but absolutely gorgeous. Crossovers are in seperate box's with a flourescent edge glass top and internal LED lighting - the components are too beautiful to hide when assembled with detail. Should be ready to finish them up in a few weeks and will post pics.

I am thinking that it’s intent is not to dampen the speaker (which is left to the materials applied on the side and back walls), but rather to minimize internal reflections with absorption, especially the lower end of the spectrum and eventually aiding the port tubes in doing their intended job better. But I think Danny can best comment on the functional aspects of the fiberglass around the port tubes.

On my build, I think I have packed it in way too dense so much so that it probably alters the internal volume of the cabinet. I intend to take it all out and try just polyfill or the fiberglass insulation much more lightly filled.

As for the finish, I am really undecided at this point, primarily for the same exact reasons you cited! Also, I only get one shot to get it right!

One of the thoughts I have been having is an all around gloss black with detachable veneer sides. That way, I can have the best of all worlds....They can be rosewood one month, cherry another, maple the third and all gloss black too!!

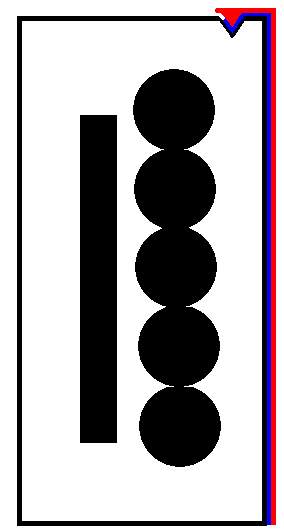

Attached drawing is one of the ways I was thinking I could do it.

* The Black is speaker frame.

* The Blue is weather/sound proofing strip (Not the vinyl covered one, but the one that’s like felt or dense soft fibres. Or probably something similar that is usually used as lining behind the mount on a speaker driver frame. Goes around under all edges of the veneer side panel.

* The Red is the Hang-On veneered side panel.

The veener panel can be made in 1/4" thick MDF. This thickness has almost even density throughout. Is heavy enough not to become a diaphragm and it's weight pivoted off the top of the speaker should keep it steady. The continuos felt/fibrous strip lining will keep it from rattling against the speaker and will give it something to rest on while also “sealing” the airspace between the speaker and the hang-on side so that the hang on side does not become a “port”.

The groove on the top and the extension of the side over the top won't be as big and prominent as it looks in the attached drawing.

Easy on - Easy off leaving a clean looking speaker when taken off!

Another thought is to use very strong magnet discs at all four corners of the snap-on veneered side. Positive is that it's easy to do, negative is the magnet discs will show on the speaker side when the veenered side is removed, but their visibility may not be a problem if I can find some that are shaped aesthetically and are a brushed steel, anodized black aluminum or a carbon-fiber (or some other matching) finish.

Floating bases for sure!!

All that said, I am also struggling with my HT room plan. If I decide to go with a left to right wall to wall fabric screen, then these might end up going behind the screen in which case there is no point in finishing these! Time will tell but one thing is for sure; If I do finish these, I want to finish these in such a way so that I can change the looks once in a while.

Wow, very nice! And in only three months, sounds pretty quick to me. Great job Dinesh!!

Thanks. I had a lot of inspiration and guidance here.

As for “Only three months”….that’s what I try to tell my wife when the project comes up for discussion with friends/family. She is very quick to correct me with “Three very long months”. To her credit, she did put up with the project being executed in our living room as it was too cold to work in the garage. It was a pain cleaning up everytime after the project work was done for the day though!