Thank you jmimac351! Really appreciate that!

Sorry for the pause in updates, but unfortunately due to baseball season starting up, my time is in spurts here and there.

So onto some of the latest progress.

First, the Assilex sandpaper is legit. It’s not magic - like it doesn’t make things go any faster in terms of the process of sanding, HOWEVER, there are a few things that is a bit game changing in terms of sanding

- Super flexible - so you can really be precise when just trying to hit a certain spot or get around curves like in the wave guide

- The stuff just seems to last forever - meaning it doesn’t lose its “grittiness” nearly as quickly as a real sheet of sandpaper

- Can just vacuum the dust off it and keep going

It does a much better job at not clogging up compared to real sandpaper, however, you really do still need to be cleaning off the surface you’re sanding FREQUENTLY and vacuuming the dust off the Assilex just as frequently. I found that doing little sections at a time rather than trying to get it all done at once worked much better.

Another thing that is truly excellent about the Assilex is the higher grit number, like the 600 “Sky” sands like a 320 grit in terms of removing product, but it finishes like a 600 grit regular sandpaper - so you get a much cleaner surface with a single grit that happens to cut like a heavier grit. So I guess in that regard it could be a bit faster, but I still find this particular part SOOOOOoooo tedious

I don’t think I got any intermediate pictures on this last baffle that I was sanding, but in the past I think I mentioned I’d dropped down to 320 grit (regular sandpaper) to try and cut the orange peel faster. That was still taking way too much time so on the last baffle I dropped down to 220 and that seemed to be the “right” grit. I did attempt to use the 600 Assilex as the main cutter for the orange peel but it was like using the 320 - it was just taking too long. Ultimately, I started with 220, then touched up areas that I wanted to be more precise with the 600 Sky Assilex, and then the areas that need to be repainted and cleared, I then hit with 800 Lemon Assilex all around the general area so I can spray the paint, and then come back and do a clear to blend into the surrounding areas.

Like I said, this part is really tedious. It’s the only part I’ve not really “enjoyed” so much during the build - I think it wouldn’t have been so bad if I hadn’t gotten down to the primer in so many spots that will now require touching up.

Also, being new to the whole finishing with spray cans thing, I’m sure if I was better at it I could have reduced the amount of orange peel that I ended up with, but there’s no way to know the “right” way to do it without actually doing it!

So here’s some photos…

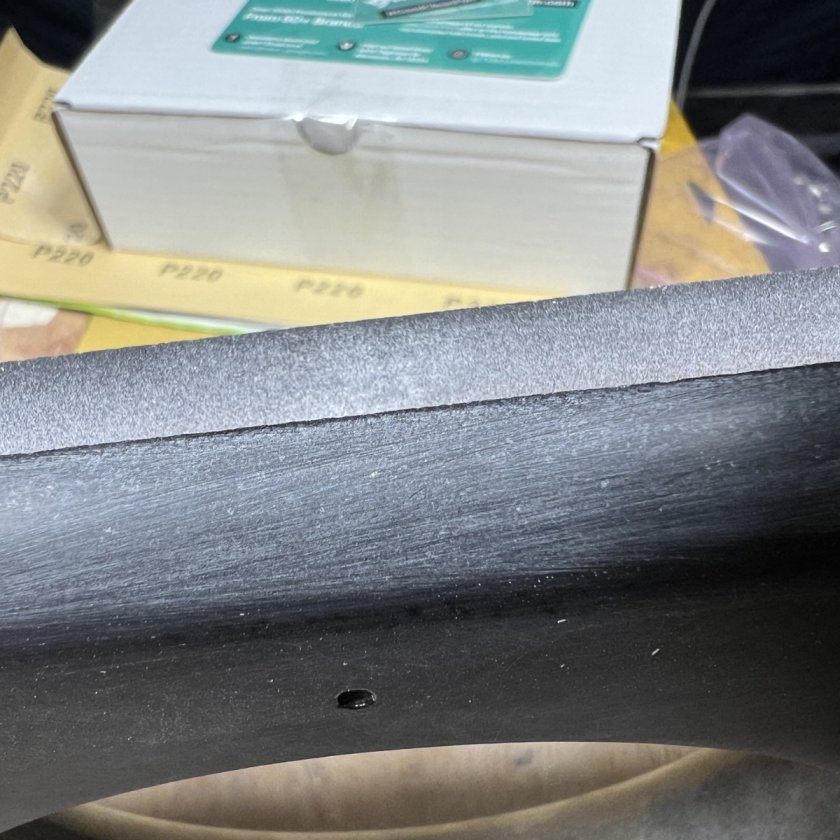

Here I tried really hard not to touch the very edge while sanding the round over on the baffle. I think I did much better on this one than the first baffle.

A tiny spot at the end of the baffle that needs to be touched up.

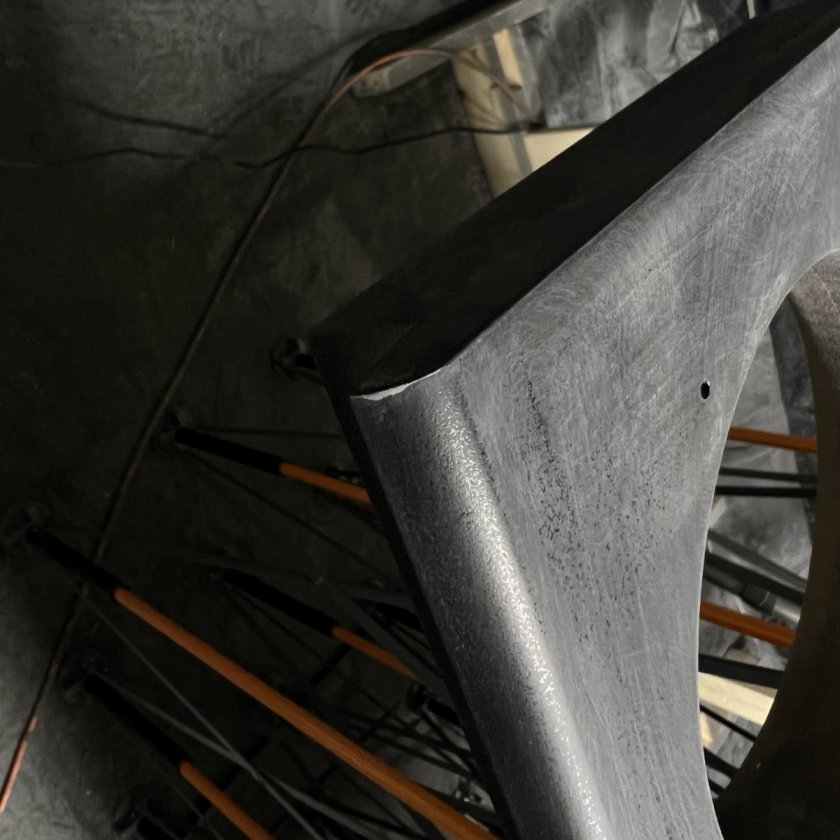

Another tiny spot at the other end of the baffle that needs to be touched up.

Here’s a shot of the round over where I sanded down to the 600 sky Assilex.

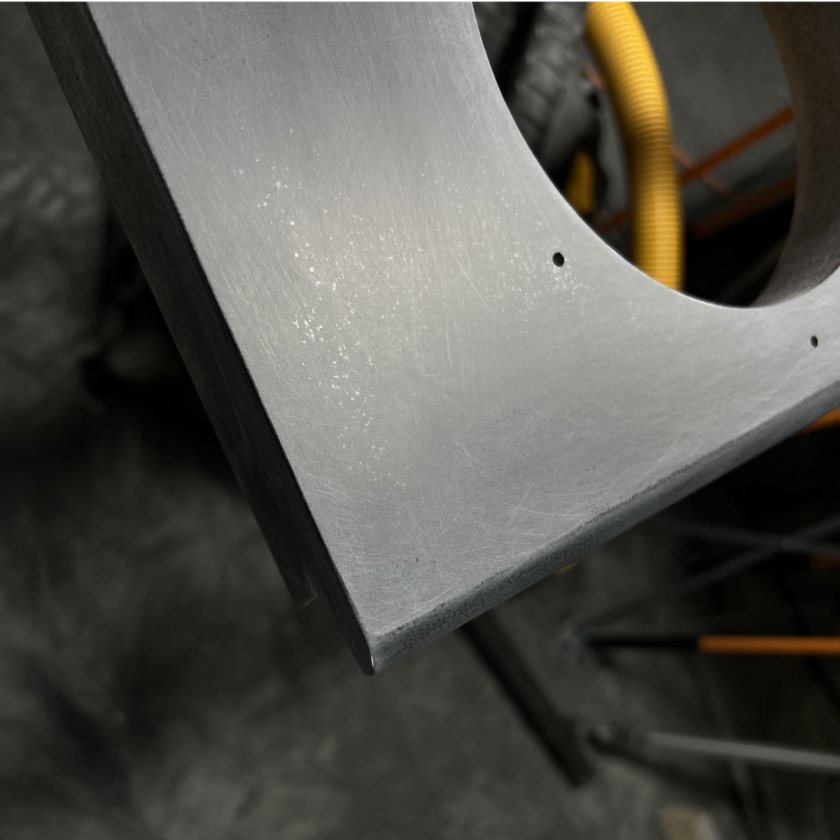

Here’s a picture of one of the speaker openings where I got down to the primer - I think I’ll probably just tape off the baffle later and maybe hit this with a small bit of clear coat - this doesn’t have to be pretty because it’ll be behind the installed drivers.

And lastly here’s the wave guide sanded to 800 lemon Assilex and the surrounding area ready to be touched up with paint and clear.

Next up

Next upSomeone please tell me if I’m barking up the wrong tree - but my current goal is to sand to 800 lemon Assilex around the areas that need to be touched up - then as nlitworld suggested, hitting it with a scotch pad. Spray it off with cleaner/degreaser, then just lightly spray the areas to re-cover the primer…then, after that’s filled in nicely, come back and spray a couple coats of clear directly over that and just barely fan it to the surrounding areas so I can sand it back and blend it in when it’s dried.

If that sounds wrong, please let me know. My guess is I probably won’t make much more progress on this until this weekend.