40 years ago I came up with a simple to make plank door design that has withstood the test of time. The rustic plank door was a customer favorite and I made many variations over the years.

I used kiln dried C&Btr full rough, plain sliced Douglas fir. No lumber yard stocks this wood, it is always a special order of 500 to 1000 bd ft. Tell the supplier you want to buy a unit and they will talk to you.

Vertical grain fir doesn't look as good for a rustic door and it costs a lot more. Vertical grain fir also splits along the grain in Tucson's 5% humidity.

Construction fir works too. Make a level area to stack and sticker the wood, cover the pile with tin if outdoors and put a lot of weight on top, that way only half the boards will twist. The planks that stay straight and flat are used for the stiles. The twisted planks are cut for the panels. An alternative affordable wood is S4S Philippine mahogany. Don't use alder, it rots quickly outdoors. #2 pine will work but it is real wet when you buy it and pine moves the most during seasonal changes, french doors could change 3/8" in width between dry and wet weather.

I always used traditional mortise and tenon joinery with waterproof glue, every door I made is still working perfectly, none have ever sagged or came apart. The joinery also take a fair amount of skill and a lot of time.

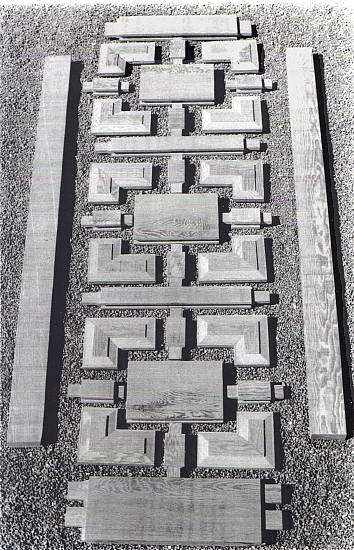

The Quick and Dirty Plank Door41 years ago I experimented making a quick and dirty plank door using construction fir. Total time to make: 4 hours.

No fancy joinery is involved, every joint is a butt joint. Once all the pieces are cut to length, put a dado blade in a table saw and cut a 1/2" wide, 1/2" deep dado on each side and the ends of every piece. The stiles get only one long dado on one edge, the top and bottom rails get three edges dadoed of course.

Cut 1/2" CDX plywood into 7/8" strips, cut to length and dry fit all the pieces together. You'll figure it out.

Now glue everything together using Titebond III and clamp for a couple of hours.

When dry, set the door on edge and drill 1/2" holes through the stile and into the rails using a 12" long drill bit. Two or three holes per rail should be sufficient. Approximate location and straightness, this is quick and dirty remember. Blow the chips out the hole.

https://www.acehardware.com/departments/tools/power-tool-accessories/drill-bits/23705Cut 1/2" dowels about 10" long and using a hand plane, sander or rasp shave a flat on one side so the dowel looks like a modified "D". The flat area lets the glue rise up from the bottom of the hole otherwise you will never pound it in all the way.

Coat hole and dowel with polyurethane glue and pound in. Titebond dries too fast, you will never get the dowel more than halfway. I like Grizzly Glue: Grizzly One, it is the perfect consistency, strong and cheap.

Grizzly Glue is available on AmazonLet dry overnight, trim and install.

I used Watco Exterior Wood Finish (green label) on my rustic doors. Even though the label says NATURAL there is color added. I think the color is ugly, luckily it settles to the bottom of the can. DON'T SHAKE. Pour out the finish leaving the color behind.

Day 1: Put the rustic fir doors on sawhorses and flood the wood with the Watco Exterior Oil. Keep adding oil as it soaks in, add more oil as needed for 1/2 hour. Wipe off excess and let dry overnight.

Day 2: Oil the doors again as in day 1

Day 3: Oil the door again as in day 1

Each door will absorb about 1/2 gallon, the finish will now last for years. When the finish looks dry in 5 years coat with more Watco, refinishing will take less than an hour.

Note: Rags soaked with Watco will spontaneously combust. I hung the rags on a chain link fence for a couple of weeks to dry before putting them in a dumpster. Keep the oil soaked rags far away from your garage. I have seen two wood shops burn up because of oil soaked rags, the hired help wasn't careful at all.If you make a smooth door from S4S lumber then paint is the best finishing solution. Buy the most expensive exterior primer and paint available. Follow the directions and the paint will easily last for 20 years with zero maintenance. Dunn Edwards Paint is the best in Tucson.