I can't speak for Maggies but I will share my opinions on how and why some ESL's have been known to fail.

An ESL is powered by a shackled demon who will exploit any weakness to break out and cause destruction.

The demon is the high-voltage corona, and the shackles are the opposing dielectric materials in the speaker (i.e. the air gap, stator coatings, wire insulation).

Complicating reliability is the fact that the demon must be only loosely bound, or the speaker won't make sound. The corona must penetrate and ionize (make conductive) the air gap between the stators, in order to apply the driving electrostatic force to diaphragm.

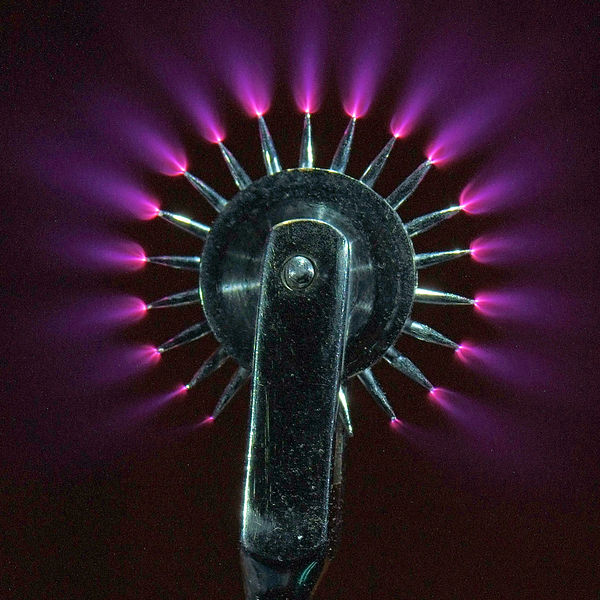

Considering the above; the materials and construction of the motor are a balancing act. The photo below shows a metal pin wheel charged to 10,000 volts of electrical pressure. Note the purple corona of ionization streaming off he sharp points on the pinwheel. When focused in that way; the corona will burn thru any insulation and result in destructive arcing.

The stator conductor(s) must be physically smooth with no sharp points or edges to focus he corona. For this reason; DIY perf-metal stators are notoriously unreliable because most DIY'ers don't have the resources or tooling to make perf metal stators reliable (Martin Logan does not use standard punched perf metal for their stators, and they are professionally powder coated-- even so; you occasionally hear of one going bad from arcing). Martin Logan does use a highly resistive diaphragm coating, which does not readily sustain arcing.

The old Acoustat ESL's were very reliable because they used insulated wire stators mounted on non-conductive plastic grids. Quite a lot of them are still playing 40 years later. And even though Acoustat used a [too-conductive] carbon-black coating on the diaphragms which was prone to arc-damage, they still played happily on for many years with hundreds of holes burned in the diaphragms-- amazing!

Sanders ESL's use milled PCB stators with encapsulated conductors (very reliable) and a highly resistive diaphragm coating and Sanders warrantees those panels for life.

Dust and humidity are not good for ESL's... as both conditions can cause arcing problems.

Martin Logans use no dust covers but they are reliable if you keep the dust vacuumed out regularly and use them in an air-conditioned environment to control the humidity. Any significant dust buildup can cause arcing and shorted the speaker life. I cringe whenever I hear that the folks on the Martin Logan owners forum actually wash their panels in a shower whenever they start losing output and sometimes that restores them.

I build insulated wire stator ESL's and I have removable dust covers that stay ON most of the time. I've never had any problems with mine.