Hello to all

JaS (aka vinylengine) is too busy this week but he indicated me this discussion a few days ago. As the vinylengine protractor designer (and incidentally the designer of a few tonearms), I feel I can add infos to this thread.

Please note that, as a French, English is not my mother tongue... all vinylengine users know that, I hope you'll be as patient as they can be with me

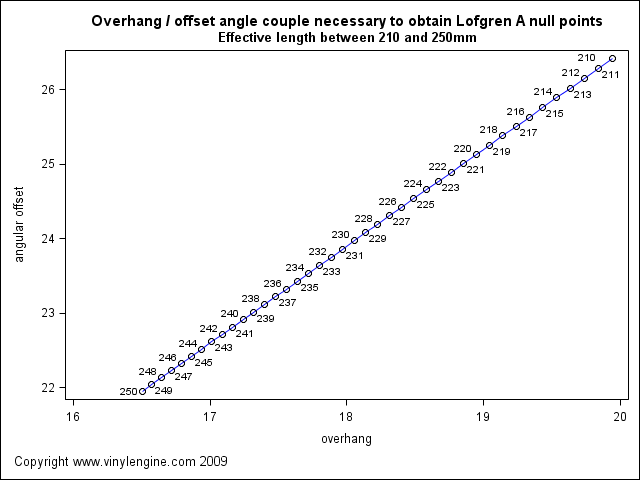

So, we all now agree on the fact that Baerwald (Loefgren A in fact) null points are unique whatever the mounting distance. All you have to do is to set up your cartridge with the correct overhang and the correct angular offset. For every mounting distance, there is an UNIQUE couple of overhang and angular offset that will give you the Loefgren A null points.

Ok, let's show this with a draw:

And if not convinced by this draw, read that paper written by Graeme Dennes:

http://www.vinylengine.com/phpBB2/viewtopic.php?t=19199Now, the two grids protractor (aka for instance, "the stupid protractor" you can download at the Vinylengine): this kind of protractor is, in theory, perfect. Since the overhang/offset angle to achieve Loefgren alignment is unique for a given mounting distance, if your cartridge body is aligned with the grids at the two null points, you'll have the correct overhang and the correct angular offset.

Now, the problem with this kind of protractor: you've just having a pair of eyes to achieve this alignment. Firstly, aligning the cartridge body is a very rough way to proceed... in fact, this is not the cartridge body that should be aligned with the grid but the cantilever, yes, that less than 10mm long piece, angled by 20? with the record surface should be used as a guide to your alignment process...

Imagine now that some people don't disengage the antiskating force when they set up their turntable... a complete nightmare.

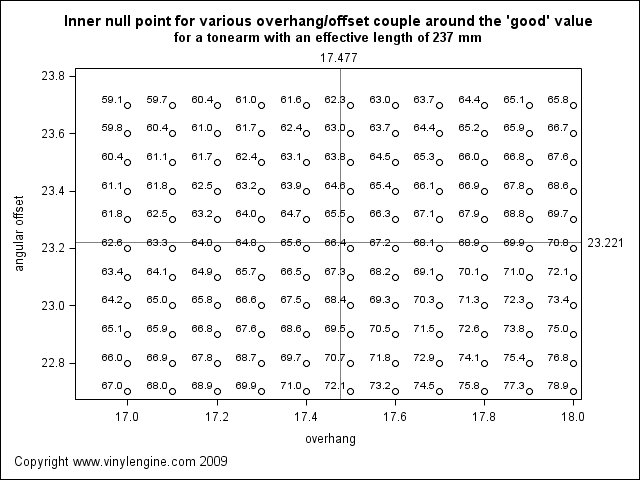

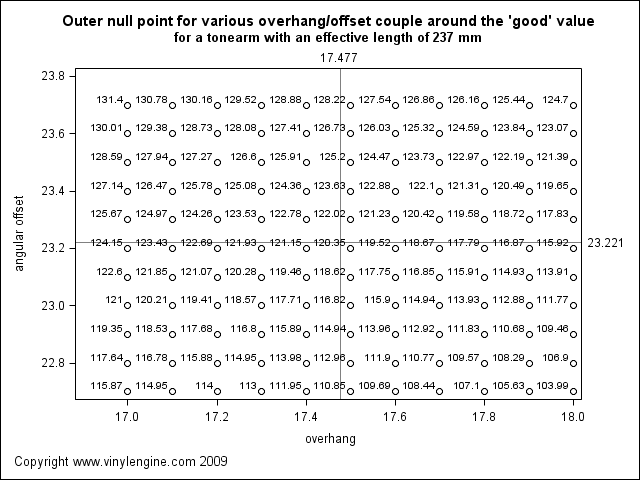

The setting process must be done very carefully. Small errors will lead you really away from the null points you'd like. As a example, consider a 237mm effective length tonearm. To obtain Loefgren A null points, your setting process should lead you to have an overhang of 17.477 mm and an offset angle of 23.221?. What will you obtain if you do not proceed carefully? Null points quite far from the one you wanted as shown by the next two draws.

So, what else can we do ?

Arc protractors could be a solution. See for instance the various arc protractors I designed for the VE. (

http://www.vinylengine.com/cartridge-alignment-protractors.shtml)

I believe that this kind of protractor, if in theory is able to give you the same null points than a two greed protractor, is more practical to use and more precise. BUT there is a condition! Your mounting distance must be exactly the one stated on the draw. If not (if the error between your real mounting distance and the one stated on the draw is superior to +/- 0.5mm, you'll go far from what you want as I demonstrated in this paper :

http://www.vinylengine.com/arc-protractors.shtmlWayner, my point now, by reading this paper, you'll see various arcs on the same draw. If now, you take a look at the Kearns protractors, you'll see lots of arcs. There is no real reason for those arcs to have a particular point in common. On the Kearns protractor, the Loefgren A inner null point is chosen as the common point, on my paper about arc protractors, two points I choose are used.

A second point: the fact that various tonearm manufacturers of the 60's, 70's and 80's choose other values than the Loefgren A values shows nothing. Loefgren and Baerwald papers were rediscovered in the 80?s. The first paper that shows that manufacturers of the past didn't understand basic tonearm geometry was written by Kessler and Pisha in 1980 and can be downloaded here:

http://www.vinylengine.com/phpBB2/viewtopic.php?t=1142Just one fact to convince you: check the data of various Japanese tonearms. Most of them (say 95% of them) are indicating an overhang of 15mm whatever the effective length. It makes no sense and there is no theory behind that 15mm.

We know more actually about optimal tonearm geometry that we did 20 years ago. Thanks to Internet and people like John Elison, Brian Kearns and Graeme Dennes. All the basic papers can now be downloaded by anyone with an internet connexion, even the Loefgren paper, in German, is now translated in English (thanks to Klaus).

http://www.vinylengine.com/phpBB2/viewtopic.php?t=15875About Graeme Dennes, if you're interested by tonearm geometry issues, do not hesitate to read his (108 pages long) paper you can download here:

http://www.vinylengine.com/phpBB2/viewtopic.php?t=4854Every formulas by all major authors are checked! feel sure that there is no 'error' in those papers wrote, most of them 70 years ago.

This is not to say that there's nothing to do about alignment issues... we're working on this

Best regards

Seb

PS : BTW, there is no 'perfect' arm in Baerwald, Loefgren, Stevenson etc... papers