How does a person best asses / measure the resonances of a cabinet?

The most powerful tool ihave used is the simple Mehanics stethoscope. You can quickly assess where the box is moving. Qualitative, not quantitative, but ifigure a mic instead of an ear or an accelerometre.

one can see resonance in the impedance sweep when the drivers are mounted in the cabinet.

It will tell yout hat some resonances exist, and at what frequency. Could be box or driver.

If a person can determine that the cabinets are exhibiting these resonances how does one determine if just damping the cabinet walls (aka with a product such as NoRes) is sufficient or if the cabinet needs to be stiffened by mechanical means?

Adding mass without stiffening is counterproductive., Someone gave me quite a bit of NoRes. After trying it i gave it all away.

If a cabinet needs to be stiffened mechanically what is the best method?

Braces. Much harder to retrofit into an existing cabinet than if you are DIYing the box. In a retrofit your only acessisthru the driver cutout, which puts significant restrictions on what youcam do. Youwill alsobesubtracting net box volume.

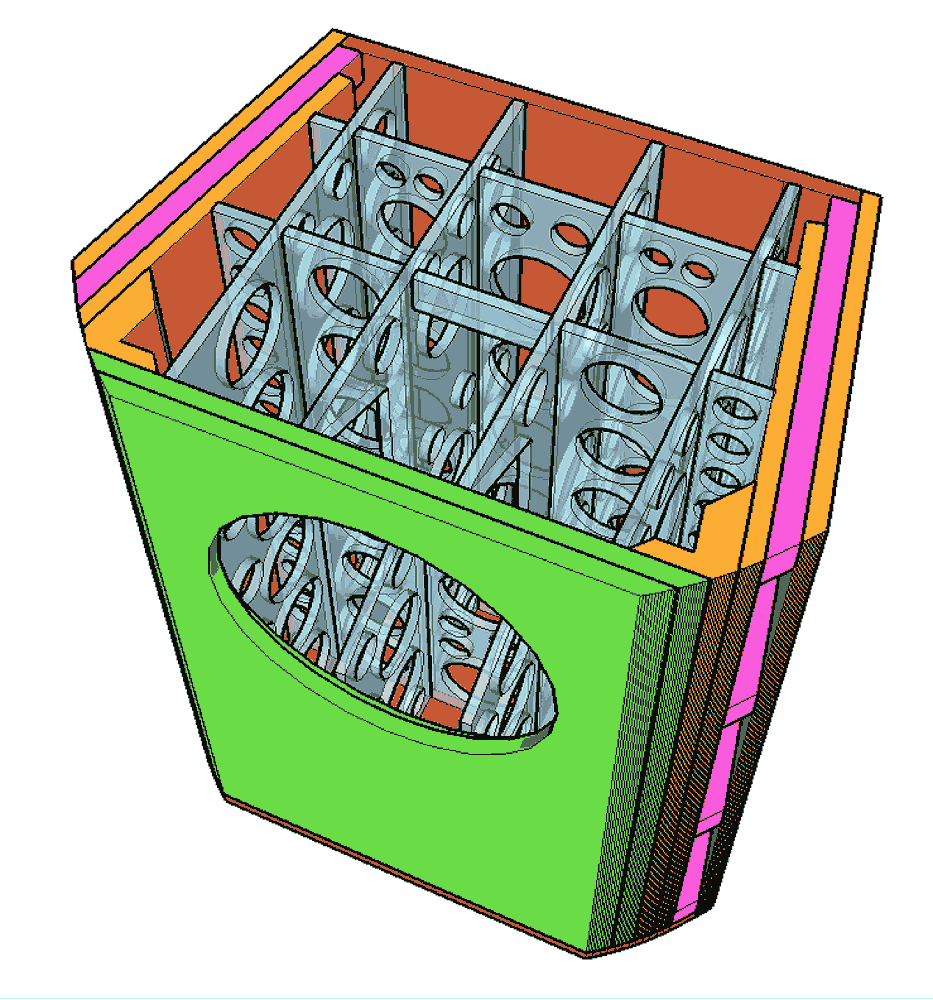

Here is a 135 litre Monster miniOnken for a TAD 16” to show the efforts imake for a quiet box:

The research Tappan did (summed up in this image) is very important to bracing implentation, i all to often see it ignored. A good example is the horizontal brace between woofer and tweeter between baffle and back.

BTW: the implementation of the above turned out very well, and illustrates use of better material than MDF for the box (bad for speakers IMO), these used stranded bamboo plywood … the best flat nsheet speaker building materials have found, and given it needs no veneer, despite high initial cost, means no material or labour veneering the [quality] plywood)

is it advisable to use acoustic stuffing such as polyfill in a ported cabinet? Or is that primarily used only in sealed cabinets?

Usual is to use lighti damping on the walls. Minimal impact on performance. It will reduce the relex action but (ideally kills higher frequency air-space resoances. In a retrofit of a reflex more than usual danming can reduce the hump often seen when slimming the volume of a reflex.

dave