The Problem with Finely Stranded Wire—and the Breakthrough That Solves It

In my last article, I outlined the importance of clean wire and the many potential benefits of stranded wire. Today, I want to address a critical question:

Why is finely stranded wire rarely used in high-end audio design? And when it is,

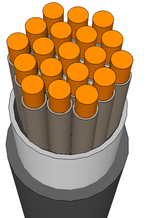

why does it often come with compromises in sound quality?At first glance, stranded wire seems ideal—it creates multiple pathways for signal propagation and increases surface area, which should, in theory, improve conductivity. However, in reality, it introduces a serious problem:

strand interaction. Many of you may have experienced this firsthand. You listen to a highly stranded cable and think,

It seems like there’s more detail, but it sounds harsh and sibilant. If you’re like me, this issue alone is enough to rule out finely stranded wire as a viable option.

The Problem: Strand InteractionWhat exactly is happening in stranded designs that compromises sound quality? There are multiple causes, but the biggest culprit is

strand interaction.One major factor we addressed in my last article:

oxidation. Removing oxidation improves conductivity, but this enhancement exacerbates a bigger problem—

strands electrically interfering with each other.Here’s a breakdown of the key strand interaction effects:

•

Skin Effect: High-frequency AC currents concentrate near the wire’s surface, meaning inner strands carry less current, increasing resistance.

•

Proximity Effect: The magnetic fields of adjacent strands influence current distribution, reinforcing flow in some areas while reducing it in others, distorting signal transmission.

•

Micro-Arcing: Tiny electrical discharges between strands create electromagnetic interference (EMI) and long-term signal degradation.

•

Eddy Currents: Because the strands are in direct contact and can move slightly, they generate internal currents that cause phase smear and signal distortion.

It’s astonishing how something as seemingly simple as a bundle of wires can create so many signal-degrading effects. And believe it or not, this is just a simplified summary—strand interaction is a deep and complex issue.

Traditional Solutions—and Their TradeoffsMost cable manufacturers, including

Hapa Audio until last year, solve these issues by using

solid-core wire—but this comes with its own drawback:

the reduced surface area does not allow for maximum signal transfer.Another approach is

individually insulated strands, which helps reduce strand interaction but introduces a new problem:

increased capacitance. Because the insulated strands are spaced apart, the overall capacitance of the cable rises, leading to high-frequency roll-off. Additionally, the added insulation results in greater

dielectric loss, further degrading performance. Ultimately, this approach is a compromise rather than a true solution.

Note the use of dielectric between strands increases the distance between the strands as well as adding dramatically more dielectric material increasing dielectric loss.

Note the use of dielectric between strands increases the distance between the strands as well as adding dramatically more dielectric material increasing dielectric loss.With so many tradeoffs, the question becomes:

What is the ideal solution? The answer, emphatically, is

Aerogel.Not just any Aerogel, but specifically the

Aerogel solution Hapa Audio has pioneered since day one. Our patented Aerogel technology is unique in that

it behaves like a liquid while being a solid.When applied to stranded wire, our Aerogel solution

permeates the microscopic gaps At the micron level between strands. Unlike individually insulated strands, which increase capacitance by introducing space between wires, Aerogel

separates strands without increasing their distance from each other. This means:

•

Strand interaction is reduced to near zero. •

Capacitance remains low. •

Dielectric losses are minimized, since Aerogel is the best dielectric material known to science.A True First in Audio Cable DesignThis breakthrough, combined with our oxide-layer removal process for copper and silver wire, creates

a world first in audio cable technology. For the first time, a stranded wire design exists that eliminates strand interaction

without any compromises.This is the kind of innovation that

redefines what’s possible in high-fidelity audio.Please stay tuned for some sneak peaks of products that use this exciting breakthrough technology that will be debuting at the Southwest Audiofest.