I purchased a pair of Super Minis from another AC member several months ago. They were assembled from a flat-pack, but not finished. Crossovers were not mounted.

The first thing I did was add a filler piece of MDF to extend the edge of the base on the short wing side to make it even with the outside of the short wing, getting rid of the notch you can see on the Super Mini to the left. The Mini on the right has the filler piece glued in place.

Next, I filled in all holes, cracks and gaps where pieces were joined, including the driver mounting holes on the inside of the baffle, using small dowels and epoxy on the mounting holes, epoxy on the other holes and small gaps, and Bondo on the larger gaps.

While continuing the prep work, I contacted AC member Nlitworld who has offered to advise others on their painting projects, and he offered to give me a hand. After describing the project to him, Lloyd replied with a list of supplies to purchase, including personal protection gear, the correct paint, wiping cloths, tack cloths, cleaning solvent, complete with part numbers. He provided information on how to set up a spraying area, and detailed instructions on completing the prep work, how to spray, what to do between coats.

THANKS LLOYD!!

This is what the spraying area looks like, set up in the middle of my new garage:

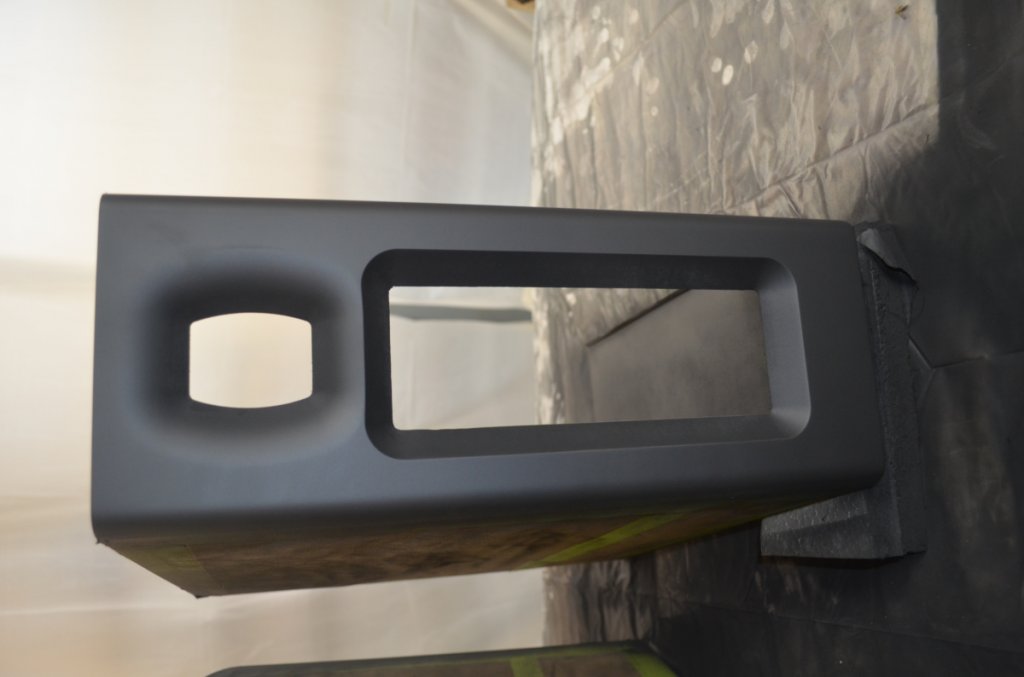

One of the Super Minis after the final primer coat:

Both Minis after the first two coats of epoxy-based semi-gloss black, applied 10 minutes apart. They look pretty good from a distance:

But up close you can see some sags at the top edge of the baffle on this one. It happened when I sprayed the top edge of the baffle from the rear--some of the paint seeped over the edge:

And on the other Mini, a sag near the right edge of the baffle and orange peel on the rounded edge of the baffle:

I'm sure Lloyd will tell me it was just too much paint. These coats were applied Tuesday afternoon. The paint needs to cure a few days before the mistakes can be sanded away. I'll do that tomorrow and respray with the final coat in the afternoon. One of the most frustrating things about this process is waiting for the right weather to be able to spray. I need temperatures between 65-80 degrees with 40-60% humidity. We just don't get that many days like that in Ann Arbor. If I don't get this done tomorrow, who knows when I'll have another chance. If we don't have an Indian Summer, it could be next May!

The Wings or sides of the Super Mini will be covered with a highly figured mahogany colored veneer, pomelle Sapele. I want to finish it with a super-high gloss to contrast with the low gloss baffle and edges. Lloyd has me fixed up with an epoxy spray that looks great, but because I'm running out of good weather, I may need a Plan B. I made the decision to paint first and veneer later. We'll see if that was a good decision or not....