Well, this is a good a place as any to discuss and I'm in a writing mood!

I suppose by my nature, I question a lot of things. Driver mounting hardware falls short of good in a lot of ways, IMHO. The conventional wisdom of using self-tapping screws has become the norm, but selection of head style, color and driver type is slim. Even slimmer when one considers that many self-tapping screw threads aren't designed for wood at all, much less MDF. They're just not optimized for wood.

Some years ago, I started messing around with machine screws for mounting, mostly because the head type and color I wanted was readily available. Tapping and super glue, screw in threaded inserts, T-nuts, etc. all left something to be desired. They solved problems, but created different ones.

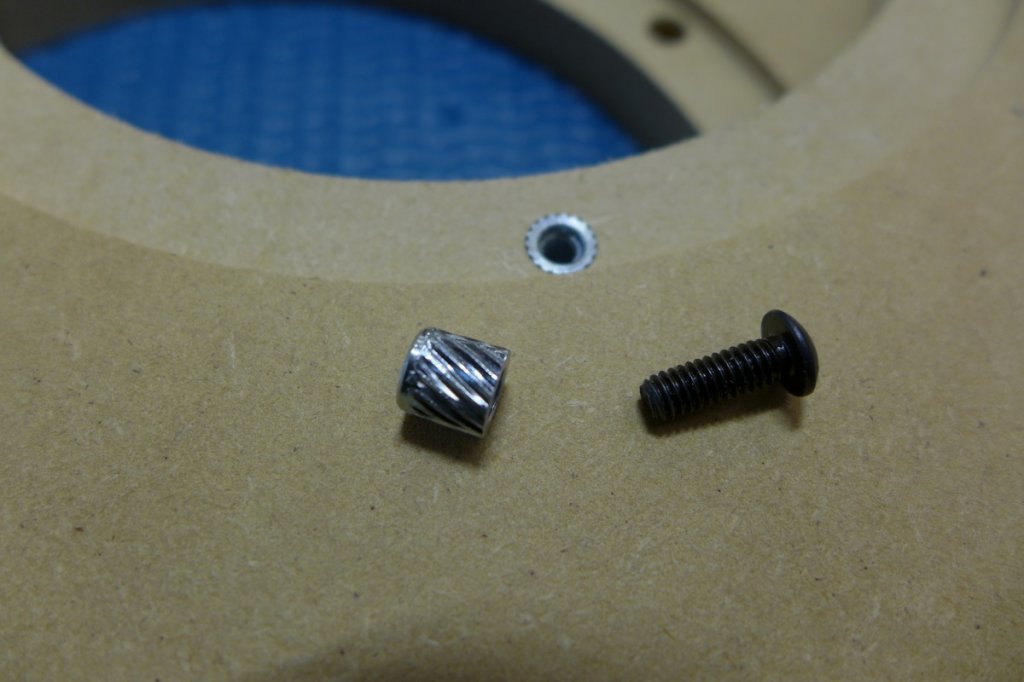

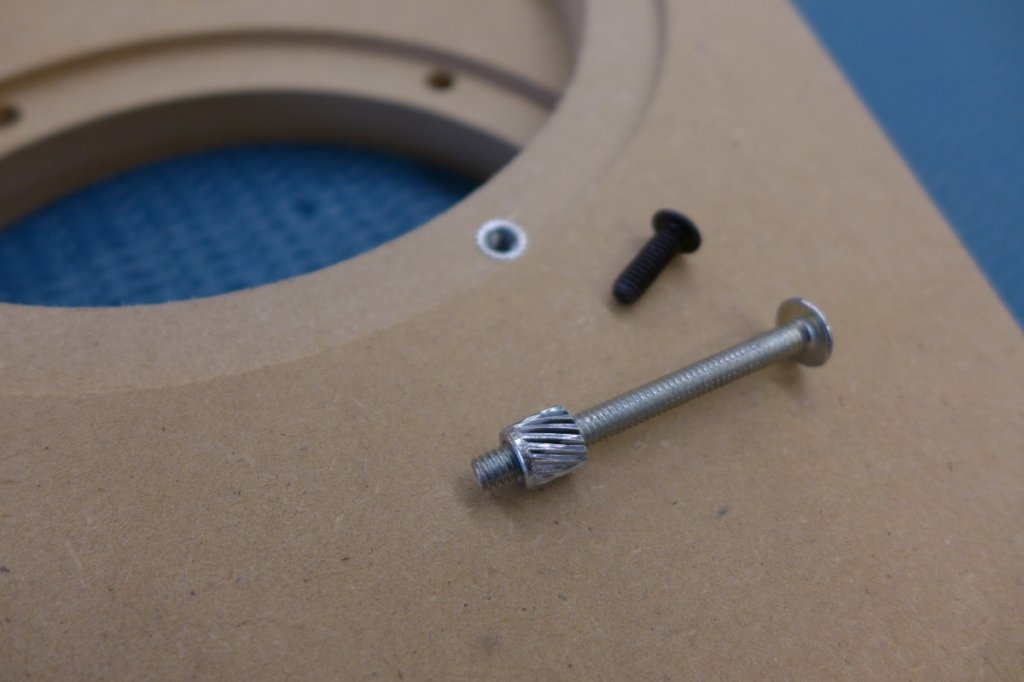

I started looking at epoxy-in threaded inserts, but all I found had closed ends, which meant that screw length was critical, yet another problem introduced. Because I like to nose around for the obscure, I became aware of a very similar design that was marketed as a press-in design for metal. Spiral knurling but with and open end. This looked promising.

I ordered some and started to experiment. Pull out resistance, ease of installation and outer diameter all looked promising. I've hung 20 lbs. of a single 8-32 insert in MDF and am convinced the MDF would fail before insert would pull out and would certainly match or exceed that obtained with a tapping screw. With proper drill size, they're easy to install. I finally was checking off all boxes. I do use good epoxy, but I don't know if that makes a difference. I like the heavy body and strength of System Three T-88, but I'm sure it has equivalents.

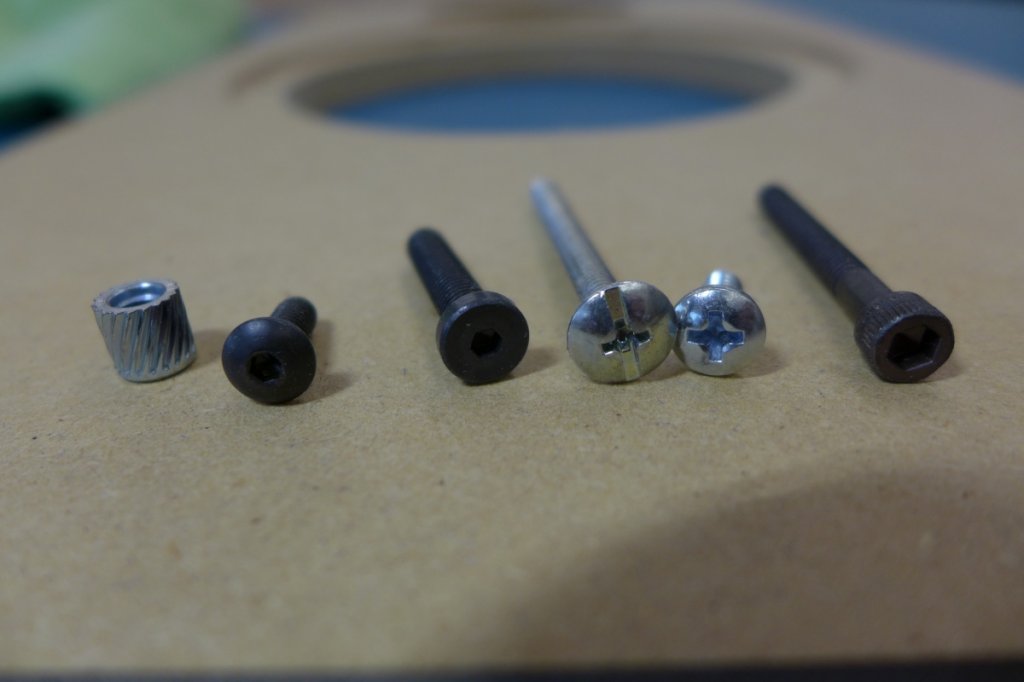

They're a little fussy to install, so I doubt it will gain traction in the commercial world. I've developed a technique that maybe needs a video or at least a pictorial but, it seems like a perfect solution for the DIY world. Screw selection is great, I've pictured a few as well as a link to McMaster page where I found them. The only possible caveat, and I haven't yet tested, is that the lack of taper on threads may cause them to loosen over time. Easily solved with a bit of low-strength Loctite, but I'm not sure of the necessity. Once I get theses fleshed out, I'll be able to test for that very thing in the real world.

I should add that with 4-40, 6-32, and 8-32 I can cover most any installation. 10-32 might be useful but have not found a need yet.

Here's a link to a video showing how I install these:

https://studio.youtube.com/video/GCRc_XyQidw/edithttps://www.mcmaster.com/threaded-inserts/press-fit-inserts-for-soft-metal/