Hey all - I don't have much experience in speaker building, so there are areas of building a speaker that I will need to rely on help from others (such as crossover assembly). What I have to offer is about 25 years of woodworking experience to hopefully add to the knowledge base out there.

I'm currently building 2 sets (4 total) triple servo subs. These call for 1" MDF for the baffle and 1.5" MDF for the walls of the cabinet. I hoped to just purchase some 1" and 1.5" MDF - but as you're probably aware there is a massive shortage right now. Therefore, I needed to laminate some .5" and .75" MDF together to achieve the desired thicknesses. This sounds simple enough, but if you just glue up some panels and slap some clamps on them you will run into problems. The center of the panels will not have the proper clamping force and you will have a bulging area in the middle of your panels that will cause all sorts of problems.

To solve this you can either use a vacuum bag and pump, or, use fasteners like screws spaced every 6" or so to pull the panels tight, OR if you don't have a vacuum press and don't want screw holes all over your panels you can use the method I will try to explain.

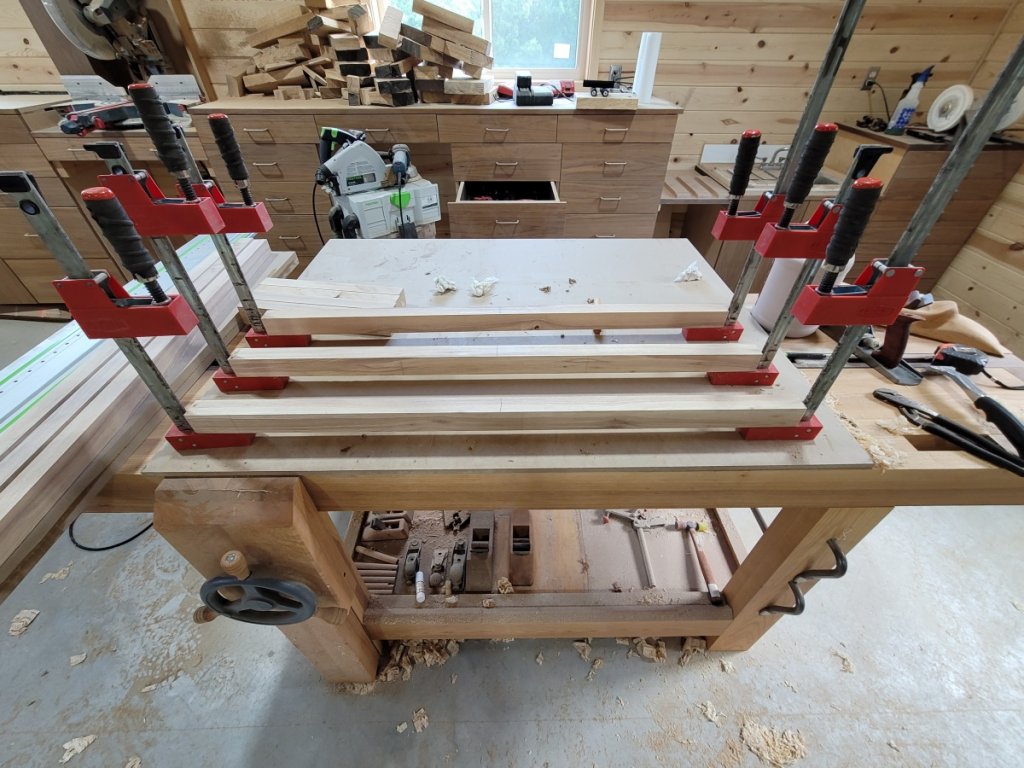

What I use are cambered cauls. A caul is simply a block of wood that spans across the item being clamped. The camber means that there is a curve on the caul on one side. You can see that this caul does not sit flat on my jointer - that is intentional. I use a hand plane and take staggered passes to achieve the curve. The amount of curve will depend on how long the cauls are and how thick and stiff they are.

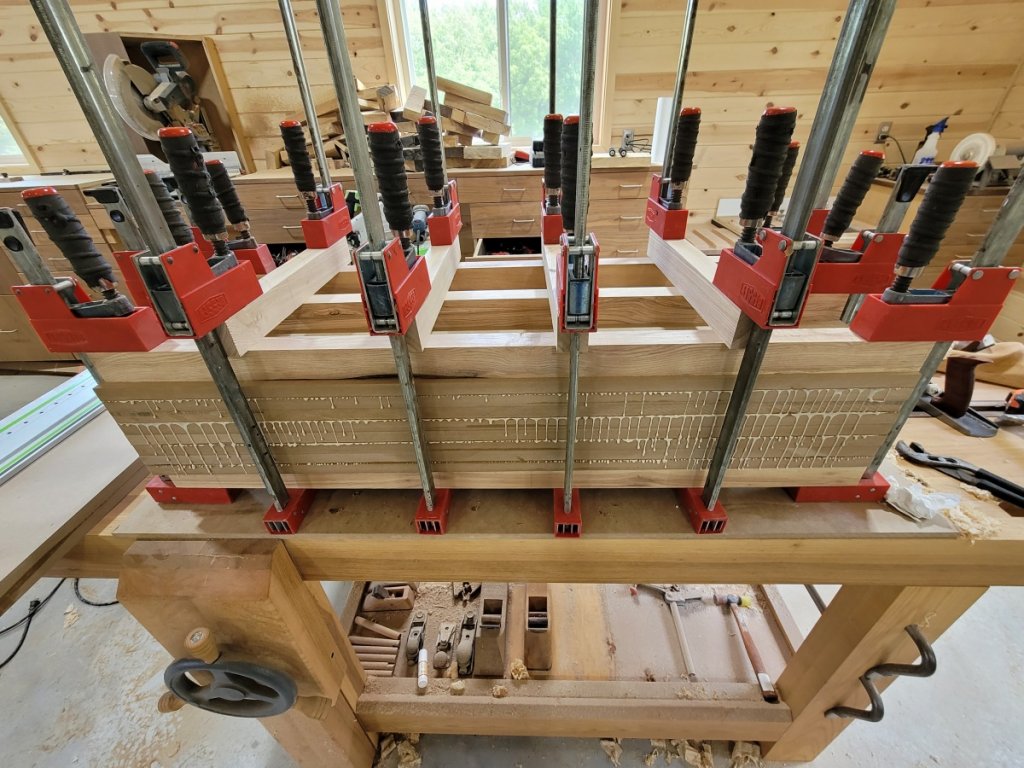

You need several opposing pairs of these. The idea is that you position them so that the cambered side is facing towards your panels (curved side up on the bottom, curved side down on top). As you clamp the outside ends of the cauls, the curved portion of the caul will exert force on the middle of the panels where clamps would otherwise not reach.

Then simply apply glue to your panels - a glue roller is helpful to achieve an even amount of glue.

Then place the panels into the clamps with the cauls as described and shown. I am gluing up several panels at once (a nice advantage of this method). To keep the panels from shifting around I use a single small brad in 2 corners on each glue up.

After you get those cauls in place, you can even add some cambered cauls running in the opposite direction to ensure that enough clamping force is reaching the middle of the panel.

That's all there is to it! Just make sure you make your panels slightly oversized. Don't try to make them your final dimension right away. You will want to trim the sides off to reach your finished dimension.

Hope this helps somone!

-Brian