So, I did it... A local guy was selling some “GR Research” speakers.. The AV/1. Guy was asking 250.00 I was able to talk him down a bit, took the drive and picked them up. I’ve posted them before when some were looking for products that may not have been in stock as an option.

Well I took that option. Some photos for you!

Gosh I hope they come out right side up in the photo.

Got them home and of course first thing take them all apart! Also, I heard something moving inside when I picked them up! Something came loose!!

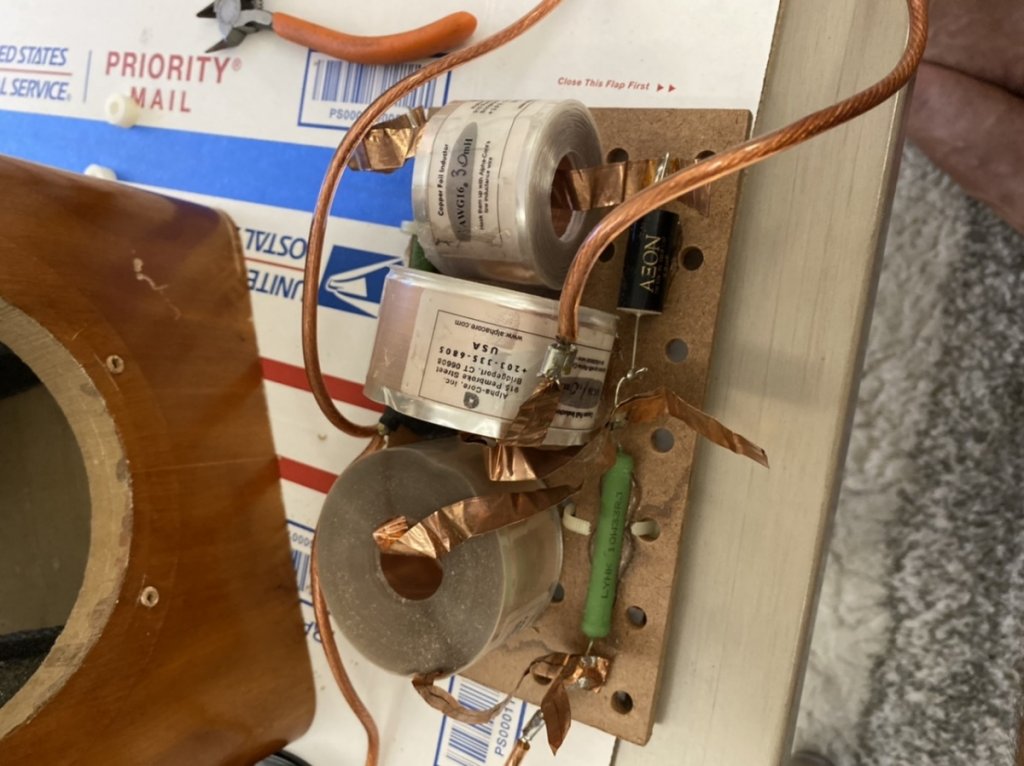

I found this!!

I was a bit shocked at the fact the guy who built these used spade connectors! More so doubling them up in places. Granted very trick idea for something. But sound quality I fear will suffer.

Now this is just the woofer network, I’ve yet to pull the tweeter network down.

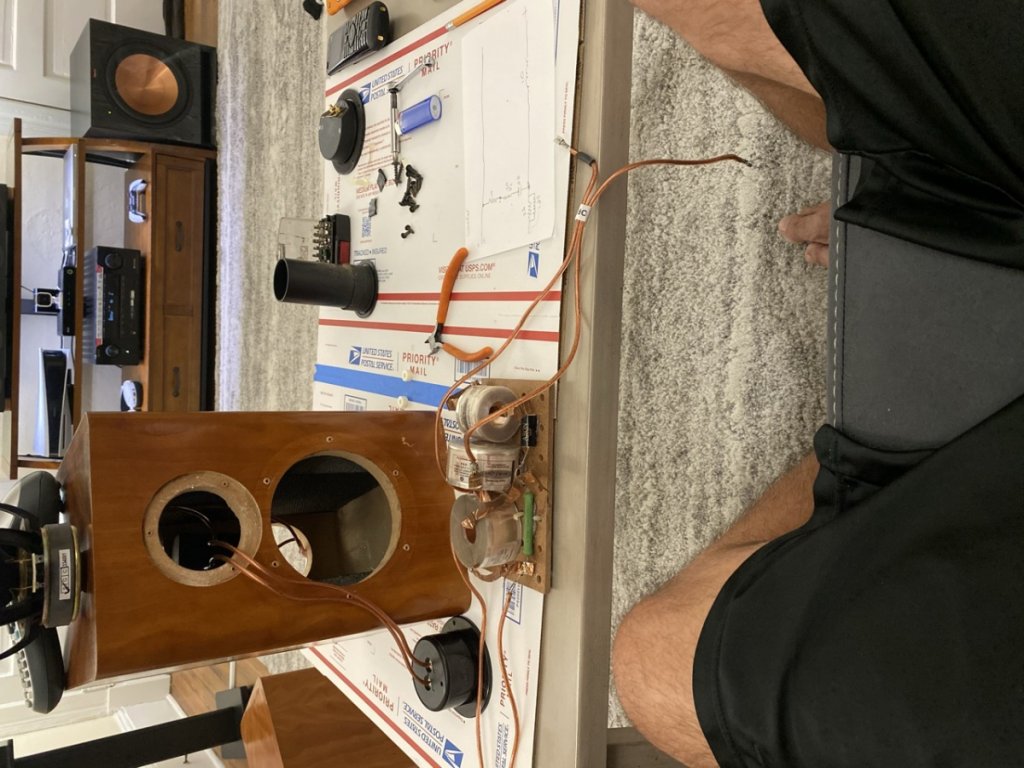

At this point I’m keeping one speaker as it is.. I’m going to rebuild the one taken apart, as well I still need to pull down the tweeter network that’s in the top of the cabinet. Anyways, I’ve found out these were not a GR build but GR products used, and made by a guy named Scott I think I was told.

So I’ve drawn out the schematic for the woofer, Next is tweet..

I purchased some nice Cherry wood that I’m going to stain (no clear coating, don’t want any goofy stuff happening inside the cabinet) re-designing the layout of the networks as well... Yup.. Getting rid of the old stranded wire. I’ll replace that with GR’s high purity copper solid core.

I’m going to fix up and measure the completed speaker, and do a side by side with the one still using the crap connectors, and the older wires. I want to see if some of my network ideas will have a positive effect on the sound. I’m going to take a new route to working these over.

I have a few different types of wood (in case anyone’s wants to play along)

Or suggestion on wood type. I think just keeping the vibrations down and making sure it’s a nice hardwood should be good. I’m not to worried about it like I would be with the cabinet itself.

The Cherry wood I’m using will be a little thicker then the standard 1/4... I chose 3/8 to give it a “firmer stance” I don’t want any vibrations. Going to use wood standoffs, as well everything will be cut by hand. No power tools other then a solder iron.

Once I’ve completed this rebuild and testing... I plan to re-do the veneer on the cabinets! As these are showing there age!

Questions, comments, concerns or (kind) criticisms are very welcome! I’m not quiet understanding why my photos come out sideways. It’s really starting to bother me. Lol.