Best laid plans of mice and men...

Or, is it - measure 4 times and cut twice.

Ok, a fixable screw up...

It seems that even practicing, measuring twice, and doing a layout of what is to be cut doesn’t not prevent errors.

Practice I did. In particular I did a practice run of the tweeter cutout with the recess. The cutting order is important here with the recess needing to be cut first, then the through hole is cut. The recess needs to be “right on” as once the hole is cut, it will be difficult to fix it afterwards.

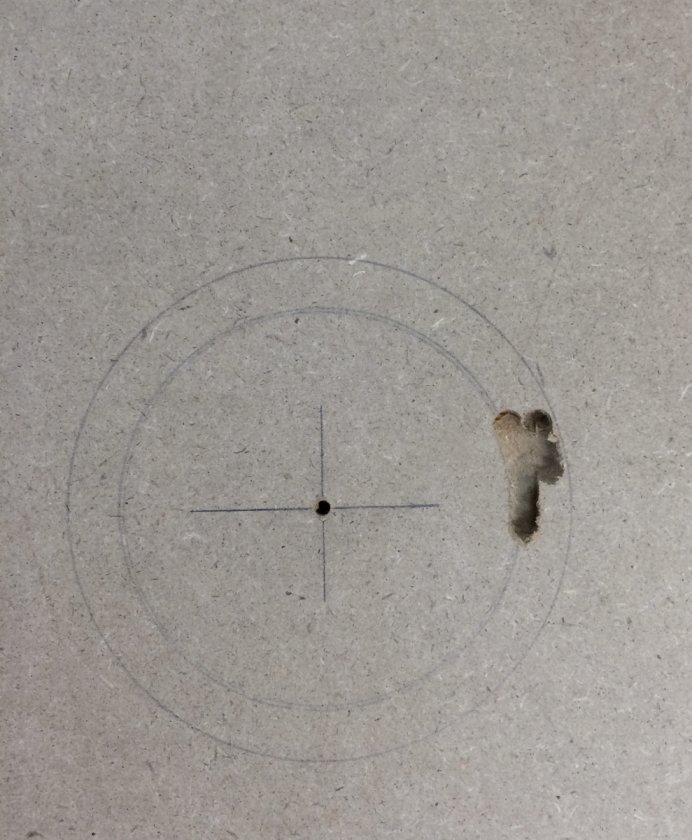

I always do a pencil layout, in particular to ensure I have selected the correct pin hole in the router jig.

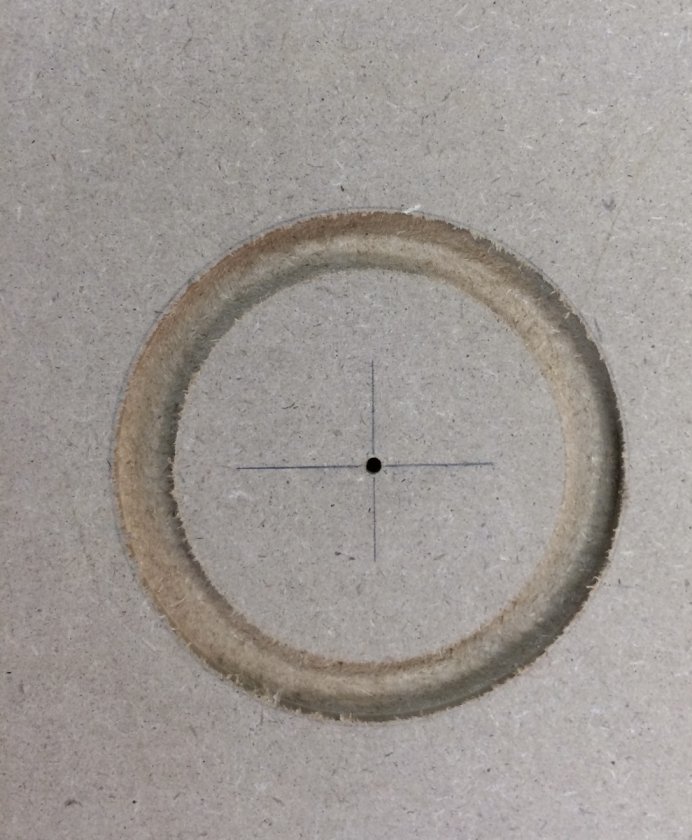

I routed the recess using an up spiral 1/4” cutter.

I was a bit surprised to see that the exposed surface was more torn up than it was when I did the X-MTMs. It could be the quality of the MDF sold at Lowes has gone down. Yup I bought the “cheap” stuff again. But, I also wonder if the cutter has gotten dull. Probably not as it has been little used. So, I going to blame the MDF. I was able to clean this up with some light sanding. So not bad.

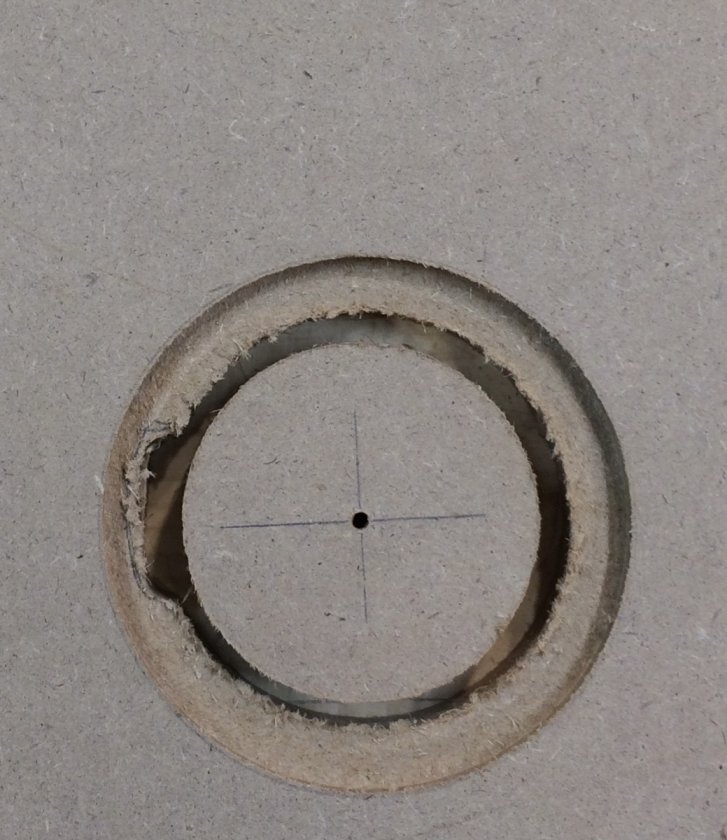

In the past I have used the 1/8” up spiral cutter for doing the through cuts in the the MDF as it draws less on the router’s battery. For the tweeter cutout this meant that I would use the 1/4” bit for the recess and change over to the 1/8” bit for the through cut. But this time I opted to use the 1/4” bit for everything. This worked just fine. The router has plenty of power to handle the larger bit and, with the hole being small, the battery lasted plenty long.

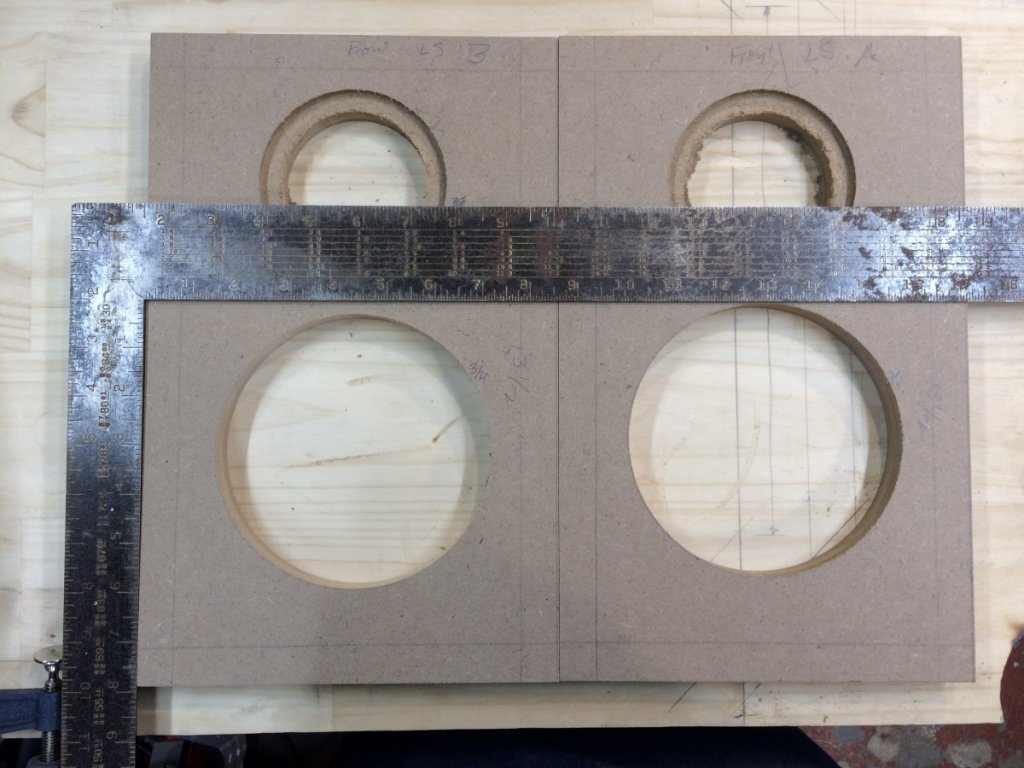

With practice done, time to do some real cutting. All went great...

Until I noticed that one thing didn’t look like the other...

Don’t ask me how this happened. I did the layout of the 2 front baffles at the same time and I used the same tape measure for both...

But it did happen and, no, I didn’t go back and check the layout a third time just before cutting. Nope, didn’t do that.

Well, after a few choice words...

I thought this would be a good time to see how good that hole cutting jig really is and I used it to cut a plug for that misplaced hole.

On the first try, I achieved a plug that was almost a perfect fit. With a little light sanding, it was a light press fit to get it into place. The thing I did notice is that the router cuts holes with a slight taper. Not a lot on a 3/4” thick piece. Maybe a total of 1/64” with the 2 pieces fitted together. Not sure if that all of the pieces and parts of the router and jig being slightly off. Or is the router bit pulling everything off at a slight angle

Curious.

The plug fit nicely and a little excess glue to ensure everything got covered well

I did wipe the glue off while it was still wet to make sure it didn’t affect staining later on. I re-did the layout, this time checking it against the other front baffle before making the cut. It is interesting that I found not only was the vertical dimension wrong, the horizontal dimension was wrong as well. I really missed the mark with this on.

With the new hole cut, I am back in business.

There is a bit of uncut material at the bottom of the holes. This is a result of the plunge cutting depth on the router being set just slightly less than the full thickness of the MDF. I do this to ensure the plug being cutout does not move while cutting it. I cut the hole in the MDF using 3 cutting depths passes so as to not overload the cutter and/or router. After I make the final cutting pass the plug pops out nicely. A little light sanding cleans all of this off.

You will also notice that the 1/8” cutter I used to cut the hole for the woofer made a much cleaner cut than the 1/4” cutter I used to cut the tweeter opening. Neither is a “cheap” cutter, with the 1/4” cutter being a Whiteside.... Hmmmm