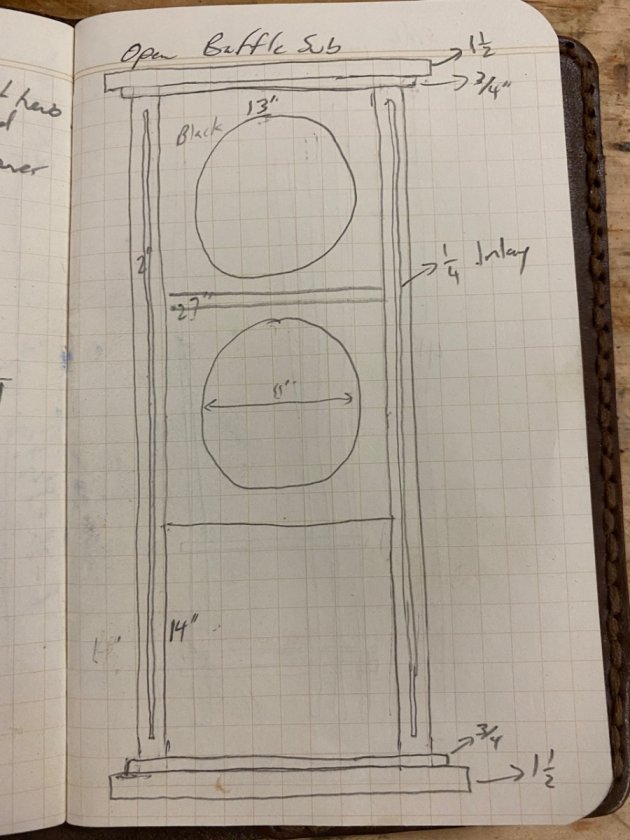

I am starting an open baffle sub and I am using wood from a cherry tree that a friend cut down. I got someone to rough mill the tree into 3 ½" boards and it has been drying for 2-3 years. I am ready to use it now. It may not look like much yet but the cherry wood really shines once it is dressed properly. Here is the design that I have come up with. I am planning to have both drivers facing forward.

The baffle will be 1½" of MDF and I will paint it black. Everything else is going to be cherry. I am not going to be using no-res. I may be wrong but I am feeling like the mass of the 2-2½" side, top and bottom panels will limit resonance. Also, the look of the exposed foam isn't really for me. The amp will be mounted in the bottom section of the build. I am pairing this with X-SLS Encores so I don't need it to act as a stand for bookshelves.

Can you see the open baffle H frame in that chunk of wood?

Its fun to take what is just this side of a tree and turn it into something like a speaker.

I had a lot of checking in some of the raw boards so I could sometimes break them apart, sometimes I had to saw them apart. Then I would mill a clean edge on each one and glue them back together to get the wide 14-15"panels. You always have to oversize your pieces in a project like this because there is always wood movement once you start sawing.

I would cut to rough length with the circular saw then strike a string line down one edge. Then I ran it through the band saw to get one relatively straight edge. This picture doesn't show the correct sequence, I can't remember why, but next I would typically take it tow the table saw to cut the wane off of the other edge of the board.

The boards are 3½" thick so I had to run it through the table saw once, then flip it over and run it through again to get a through cut.

This gave me one edge that was pretty close to flat and I cleaned it up my jointer and a hand plane.

This is why I spent so much on a bandsaw. To be able to cut through 13¼" of solid cherry is a very cool thing.

I didn't take a picture with the thickest board but here I am resawing a much smaller piece. When I did the big piece the red blade guide is retracted all the way up into the saw.

This is as far as I've gotten. Its all the pieces I need for one open baffle H frame with the sub mounted underneath. My garage is not heated so I have brought everything inside so that I can get any last wood movement happening. When you resaw wood you release a lot of tension within the wood and it is not uncommon for even quite dry wood to move after resawing. Everything is well oversized so that I can mill out any cupping, twisting, or bowing. Much of it will have to done with hand plane because my planer is not big enough for some of these pieces but I really enjoy the hand work. You will notice the checking that is still present in some of the long side pieces. I am going to fill them with black epoxy and then inset some purple heart bow-ties to hold the cracks in place. I just got the shipping notice from Danny for my drivers and the amp so I am excited for them to arrive!