Hello,

A few days ago i ordered the complete Eclipse package to used with my Scheu ( German) based diy turntable. I have asked Herbie''s Audio lab for advice but maybe here i can get some ideas too. So i copied and pasted it. Many thanks in advance. Greetings, Eduard

I came across your products and i might need some after some initial advice.

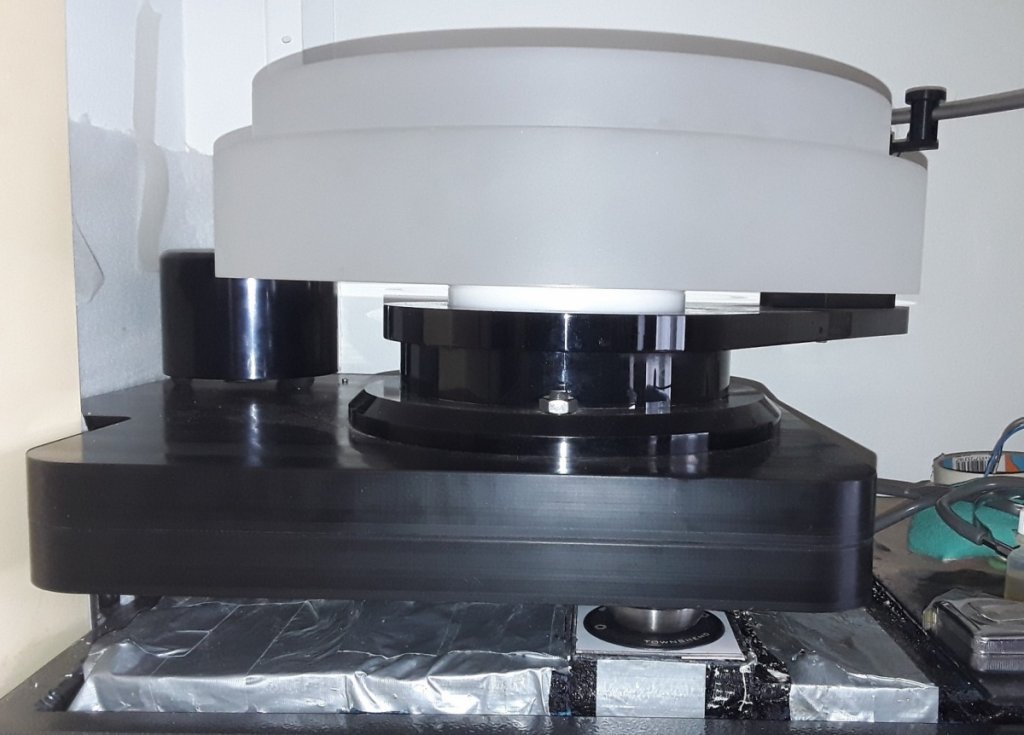

I have created a diy turntable with a 28 pound acrylic platter with inverted bearing.

The platter ( Scheu in Germany) is machined in one part the upper part 14,2 inch and the lower part 15,7 inch diameter total height around 4 inches. The bearing ( forgot but i think about 2 inches length) is in the upper part so think the belt should be there too maybe as close to the record as possible.

This week i bought the Sota total eclipse package and i wanna '' design'' a 6 inch diameter and 5.....6 inch height pom material motor housing. The original Scheu acrylic turntable chassis is filled with lead shot and then bolted directly to my '' own design '' pom plate ( also lead shot filled) . This plate will support the motor housing. The tonearm is fixed to the acrylic art of the Scheu base.

My idea was cut a grungebuster 1,8 mm ( thicker will maybe create possibility of mounting it not in a horizontal plane) gasket to put between the actual motor unit and the pom housing making the biggest '' contact surface'' possible.

Maybe one could cover the housing of the motor too?

Or create an extra '' contact area'' by resting the bottom part of the motor itself and a grungebuster circle following the electronic ( all tube based gear but their choices a easier)

Sincere greetings, Eduard ( from the idea that vibration should be dealed with as close as possible to the source .

And the final area should be between the pom motor housing the big pom base. The housing will probably be filled with lead shot to create a total weight of 10 to 15 pounds in order to stay foot.

Do you think a conical shaped housing. Smaller diameter on the top will be better to '' sink down '' vibrations. The French have done test with using rather thin double sided loudspeakers sand filled to create optimum damping. Their idea let the would vibrate and let the sand stop it. Making the panels to thick will make the vibrations stay in the panels and the sand will just add its weight