Looks great. I see your router circle jig...by any chance do you have a link or something you could share on its construction.

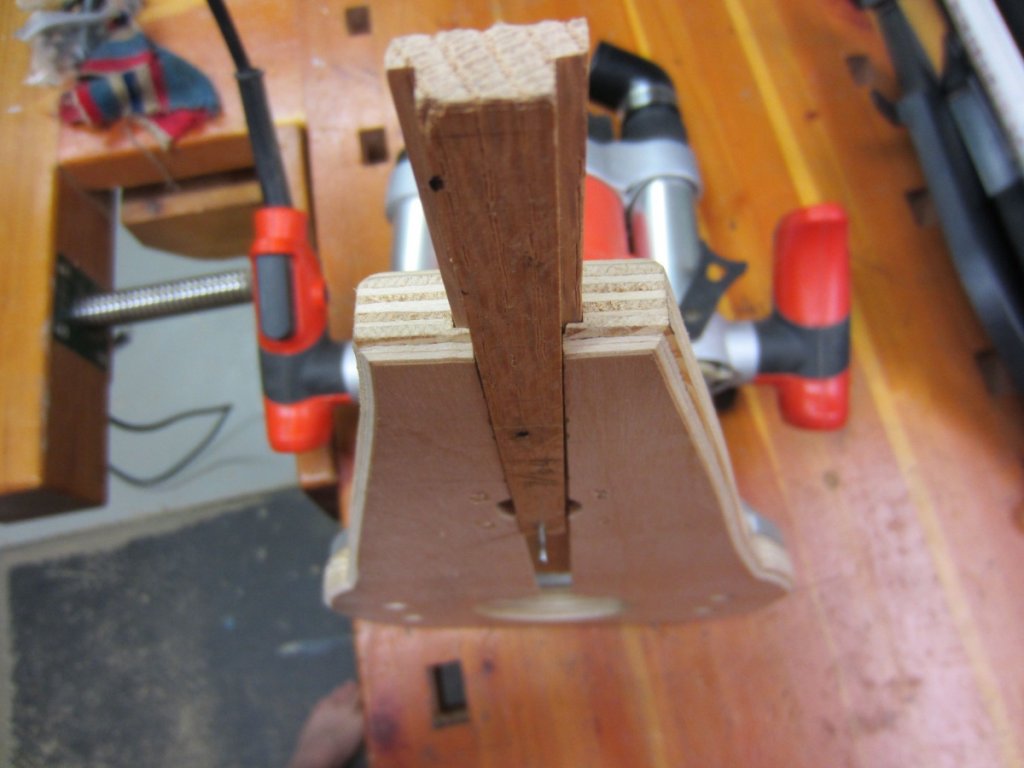

The jig is based on the design in Bill Hylton's book, "Router Magic". It is essentially a trammel that has a steel pin in a hardwood bar that slides in a plywood base. A thumbscrew is held in place with a T-nut that securely locks the bar in the base. Set the distance from the center of the pin to the outside of your router bit to the radius of the circle you want to cut.

The pin is nothing more than a finishing nail with the head clipped off that is let into an undersized hole you drill in the bar. A few holes at several location in the bar will allow you to position the pin in different location for cutting holes from 2" in diameter, on up. Drill a hole in your workpiece at the center point for your circle, slide in the pin, and rotate the router jig, removing about 1/4" of material with each pass.

I had a problem with the first jig I made with the plywood delaminating where the T-nut was installed... a result of over-tightening the thumbscrew. I added some screws you see in the picture below to prevent the laminates from separating.

A few thoughts regarding using the jig.

MDF is very messy and if you're working indoors, you need good dust collection. If you can, look for a router with good dust collection ports to pick up the fine dust that kicks up when cutting MDF.

Theoretically, I like having a the completely variable setting capability provided by the sliding bar, versus the digital setting design of some of the popular commercial jigs. In practice, I doubt that this makes much of a difference.

If you use a spiral uncut bit, be sure the router collet is clean and tight, otherwise you run the risk of having the bit crawl out of the end of your router and into the top of your workbench.