Its been 10 months since I posted this thread. I got side tracked, and just returned to this project last month. This is my 1st speaker project where I am doing the woodworking. (I had a friend build my LS-C).

The 9 month layoff took its toll. The wood was mitered at 45 deg. Excessive handling resulted in some of the edges being slightly damaged. Also, the hand fitted braces only fit well in one orientation (because I used biscuits to hold them in place), yet there were 2 nearly identical braces that could be oriented in lots of positions. So when assembling and gluing up, I didn't get it right. The result was gaps that wouldn't close with clamps.

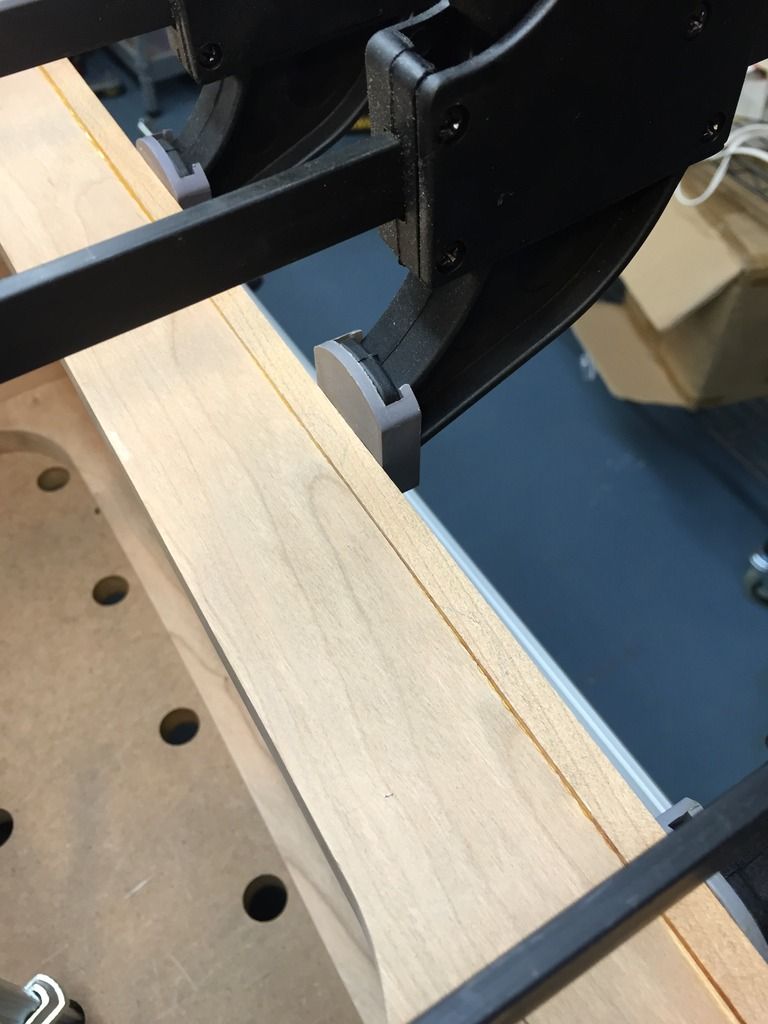

These gaps along with the damaged edges led to me to route out a small 1/4" square on each corner, and fill with a strip of wood.

After sanding, they looked pretty good.

Now, after going to all of the trouble of using a 45 deg miter (which was hard), I realized that this was foolish. For the 2nd stand, I will either just use a butt joint or a 1/2 lap joint. Each board is made up from 3 pieces of 4" wood glued up by the wood mill. A butt joint or lap joint will look similar, and so no need for the 45 deg.

Here is the stand prior to the top and bottom molding.

Here is one piece of the bottom molding after installation.

I now have everything glued on except for the top.

The next steps are glue on the top, sand, and finish, then install the no-res, install the 8" woofers and HX580 servo amp. Listen and enjoy!