Hi Norman,

We use a program called Gibbs CAM and it is hands down the best CAM program ever made. The machining capabilities are enormous and you can draw solid models

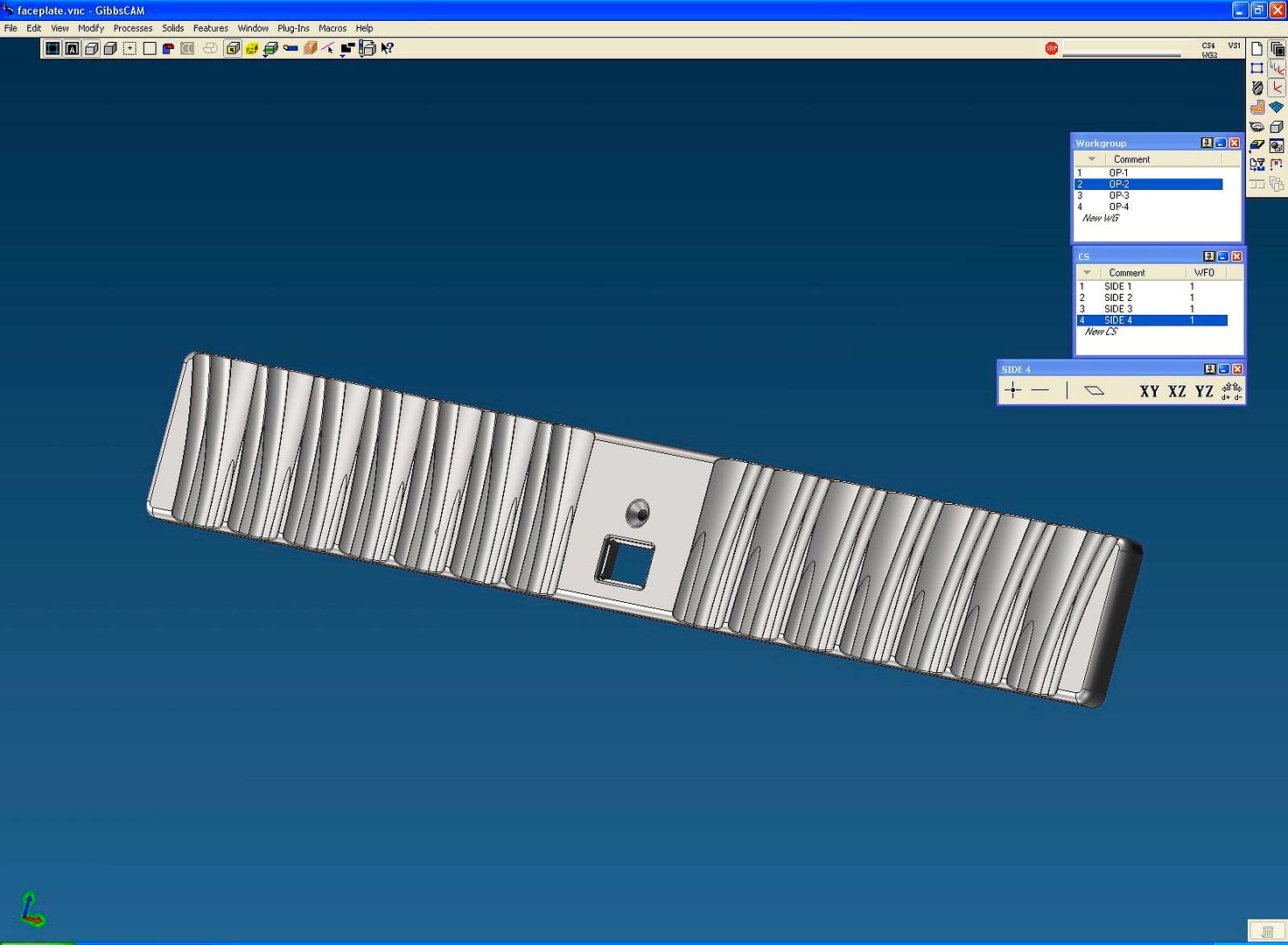

When parts get crazy, like Greg's SE-40 tube amp faceplates, we must draw a model for the machine to follow.

Here's the solid model in Gibbs.

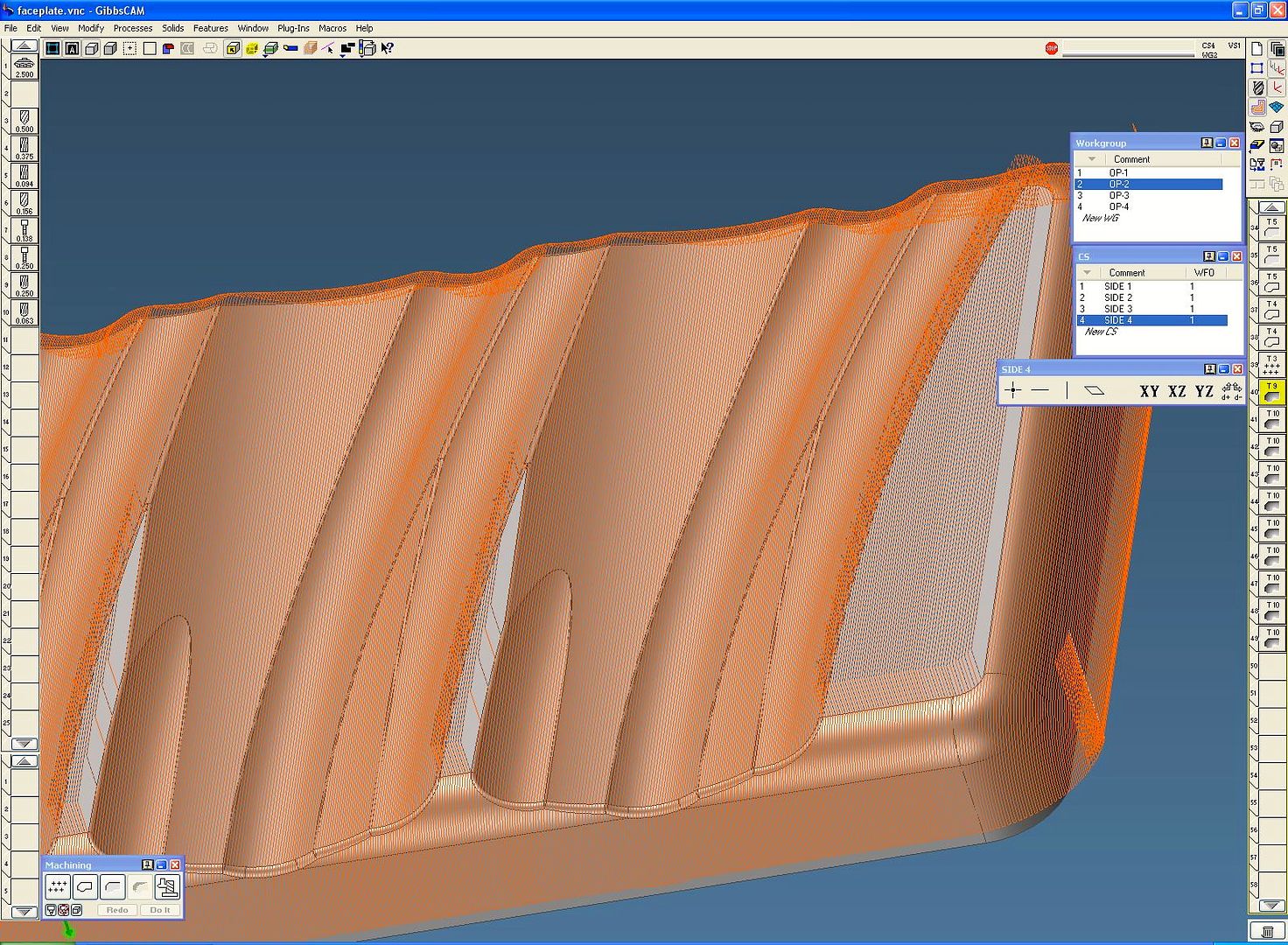

This is the tool path the ball end mill followed. Gibbs generates GM code into a .txt file, most of this contains X,Y,Z coordinate moves but always contains command codes like spindle speed, tool feed, coolant on or off and retract planes.

We dropped the faceplates off at the platers with a machined finish, they sent them off to a local polishing shop and they achieved a "jewelry finish". Nickel plating came next and just to make sure it was still shiny, they were sent off to the polishers again. Next came the lovely gold plating

It'll be cool to send out an amp case for gold plating

Best,

Matt