Hi Folks,

Here I describe how I adapted an old platter to work with the VPI periphery ring clamp. Working together with a center clamp, an outer ring really helps stabilize and flatten your LPs - I highly recommend one if you can make it work. These concepts might be applicable to other turntables and/or ring clamps. (The VPI does add about 5 lb - so be sure you think your turntable's bearings could be up to it)

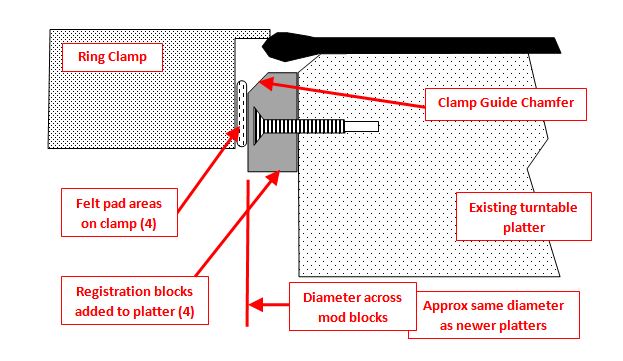

Fig. 1 Cross-section view. This drawing is not to scale but shows how the ring clamp functions. Platters specifically made to work with the clamp have an outer diameter that the felt pads on the ID of the clamp slide onto nicely - making that diameter do the centering of the clamp, not the LP edge. The platter also has a bit of a 45 degree guide slope or chamfer. My mod was to add 4 blocks to my undersize platter to make it function like more current platters.

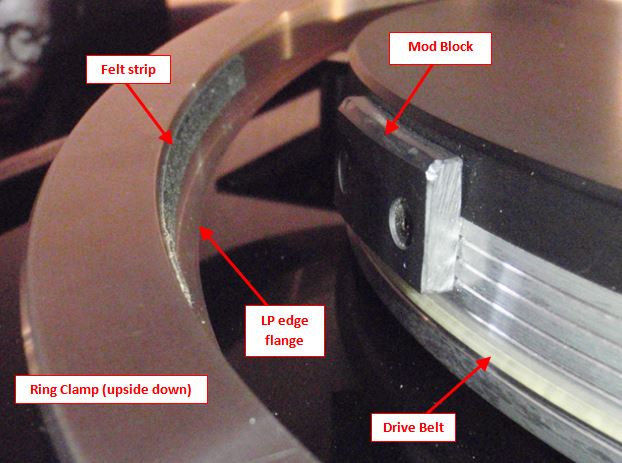

Fig. 2 Close up of mod block and ring. The clamp ring is shown upside down to reveal its details. On my turntable I did have to pay careful attention to where the drive belt rides in height and I ended up having to lower the height of the lid covering the motor pulley to be clear of the clamp ring when in use. Block mount holes were drilled and tapped with platter removed and soft-block clamped to a work table. Mod blocks might also work okay if fixed in place with good double stick tape - not forgetting, of course, to account for tape thickness. In fact this brings up a good point: I made sure to make the blocks a very slight bit thinner than the numbers indicated, and used one layer of double stick tape to make a shim to customize the fit and feel of the ring/platter. There are two locations where one can shim for fit - behind the blocks or behind the felt strips.

A very minor annoyance of this design is that you need to align felt pads to blocks each time the ring is lowered into place - of course.

For block fab I used 1/4 inch solid ABS sheet stock, cut strips that were significantly longer than needed, coarse and fine sanded them to thickness. Then I shaved off the upper corner a bit to shape that ring guiding chamfer. Then I deformed them to approx the right radius curve by overbending them around a somewhat smaller dia cylindrical object. (large dia pieces of stiff pipe of some kind work okay) Last steps were to cut the lengths I wanted out of the curved center zones and drill the holes.

If one goes to build such mods, you'll want to make more careful measurements once you have the ring. But for purposes of considering whether it might work or not for a given turntable, APPROX principal numbers for the VPI ring are: Dia across mod blocks = 11.98"; Ring outer dia = 13.6"; Ring thickness = 0.58";

Cheers, John