I'm asking myself the same question, but the moderator is the boss.

And Danny if you're still watching this.

It seems people have the same argument about PC board Xovers versus

point to point. I would expect you've tried it both ways but is there any

valid point to that one? I would have to agree on the crimp on connectors.

Also I have found in avionics work that we had some issues with oxidation

no matter how much we tightened the bolts, so to me the crimp connectors

are not the way to go.

Your best connections and the best way to maintain the purity of the signal is a point to point wired crossover. Here is a good example:

Not all point to point wired crossovers are equal though. All of the advantages can be negated by the insertion of a bunch of common electrical connectors. Here is a good example.

A joint with multiples of these things held together with nuts and bolts is even worse.

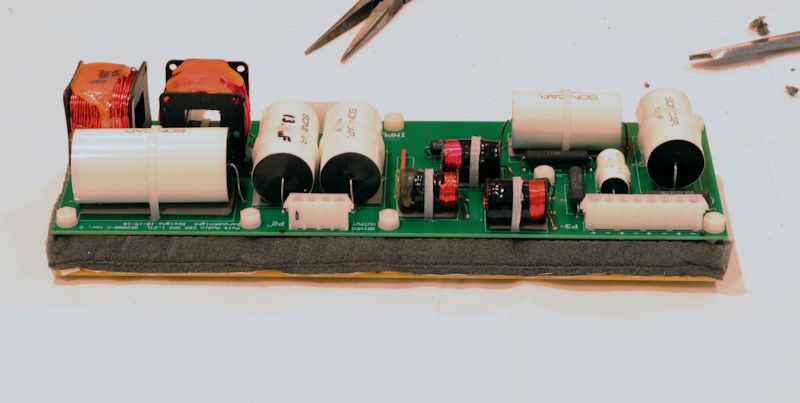

Not all circuit boards are equal either. Some are quite good. Nice wide heavy pure Copper traces work well and do not degrade the signal too much. If the conductive element is a thin aluminum film then that is going to be a problem.

Also check the connections on a circuit board. Ideally you want the wiring to slide right into the circuit boards where it is soldered right to the Copper trace. Like these...

You don't want to see connectors built onto the circuit board that allow bare wire to be slipped in and tightened with a steel screw. Like on this one...

Binding posts can also be a major issue as well. There has to be a connection there at the speakers. But the quality of this connection can vary a lot. And in some circumstances you'd be surprised at how much difference can be made in that area.

In general you want the least number of breaks in the wire and the least amount of material possible in the signal path that isn't a high quality wire.