Here are the instructions in photos.

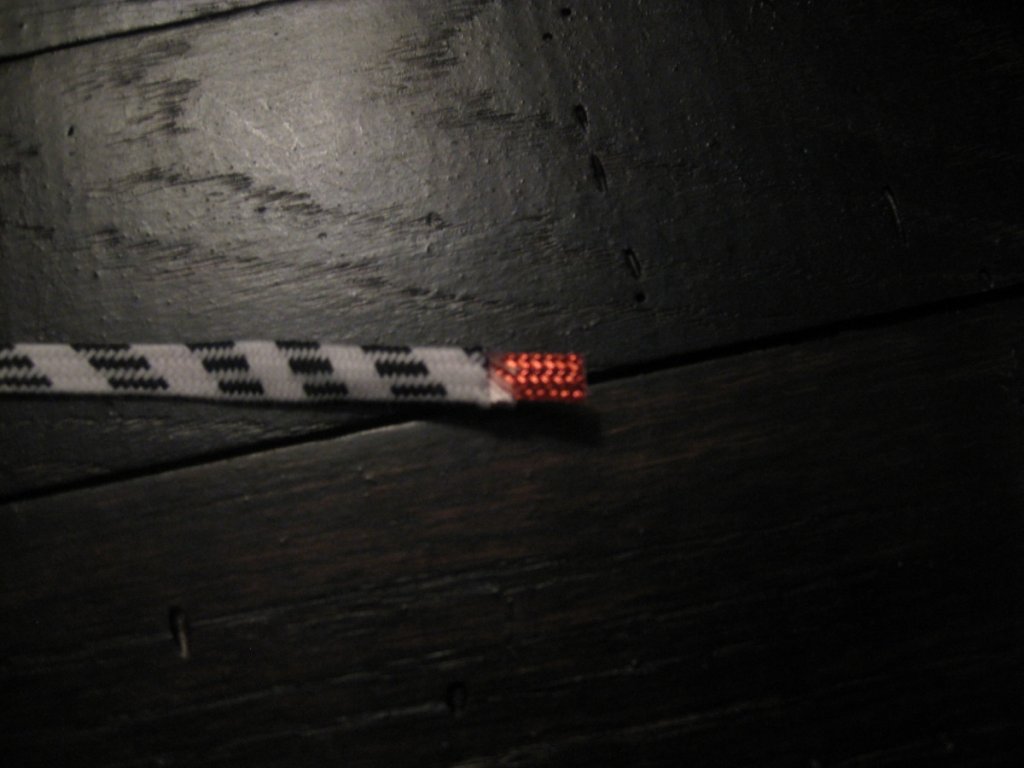

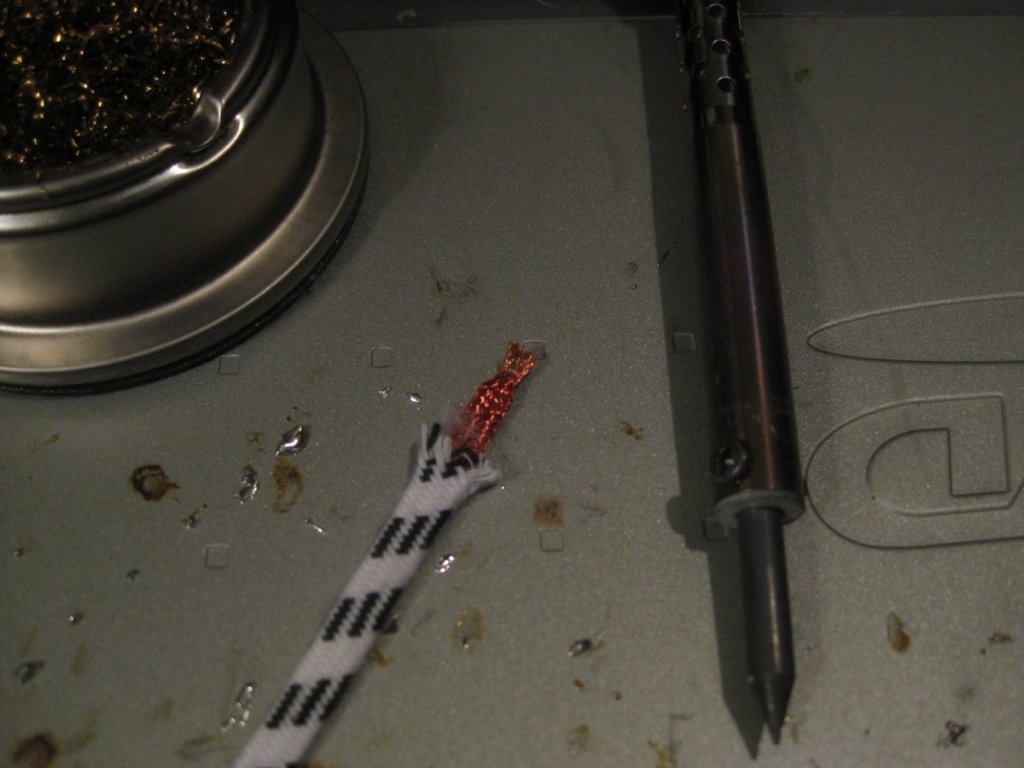

Pull the cotton back to revel the wire. Notice the red color due to the enamel coating

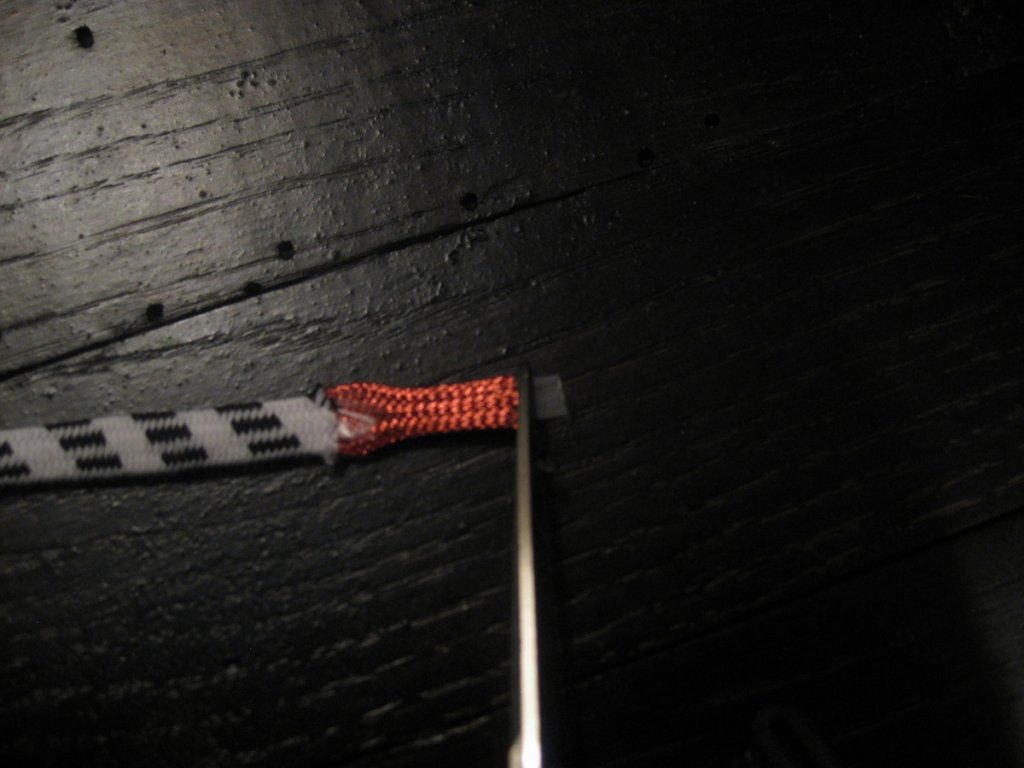

Cut a small section of the rectangular poly core out

Round the cut so as to leave no sharp edges

The wire should now look like this

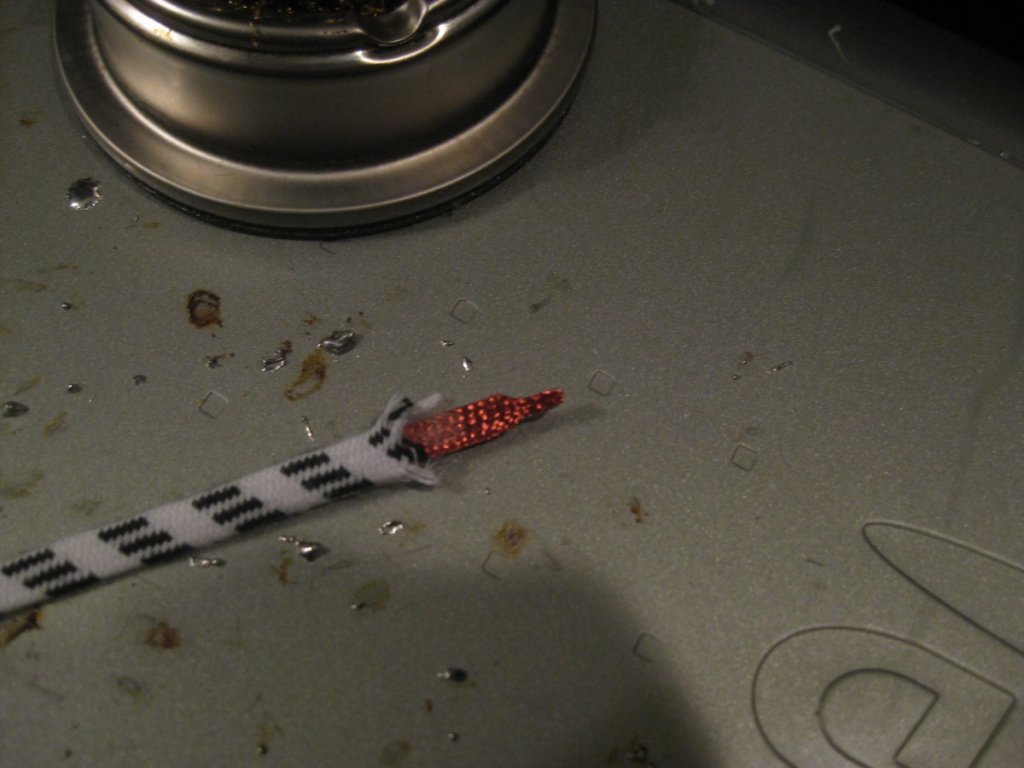

Apply flux to the bare wire

You need a hot solder iron +500f to burn the red enamel, notice the wire is now copper colored

Add solder to the wire and be sure to burn off any residue

Cut a very small amount of the insulation from the ground wire

You only want a little bit of wire exposed

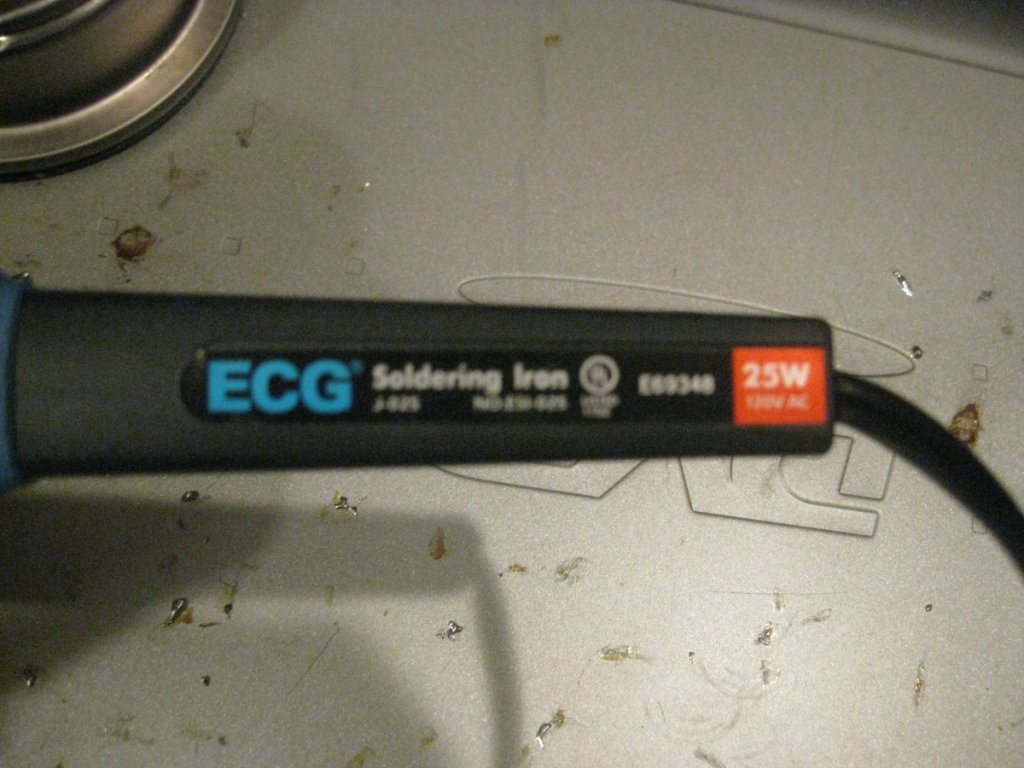

I use a 25w iron to work on the plugs

and a 60w iron to burn the enamel coating

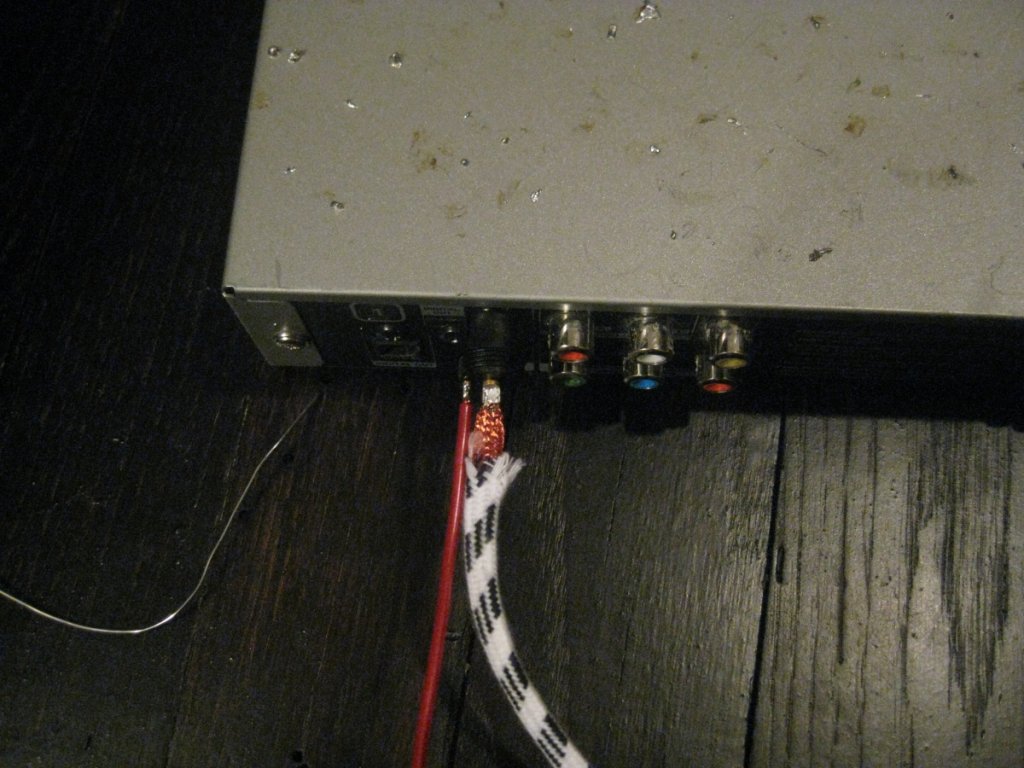

Plug the ETI connector into your throwaway player be sure to do it this way as the shell holds the delicate ground pin tight

Remove the shell to revel the wire points

Add solder to signal and ground pins

Now solder your pre-tinned wire to your tinned signal pins. You want to go quick but give it enough heat to fully melt together

It should look good

Solder the pre-tinned ground wire to the pre-tinned ground pin

It should look nice and clean

Side note, this is how you get consistent cuts of tubing material

Now get your hot glue gun out. Notice the solder pot in the background. Also an excellent way to tin wires

Add hot glue to the joints. Be sure to cover any shorting possibilities

Slide the flex wrap down to the connector

Slide the shrink tubing onto the flex wrap. This is easier if you start with the flex tubing longer than the wires

Use heat gun to shrink the tubing. Be sure not to melt the flex wrap

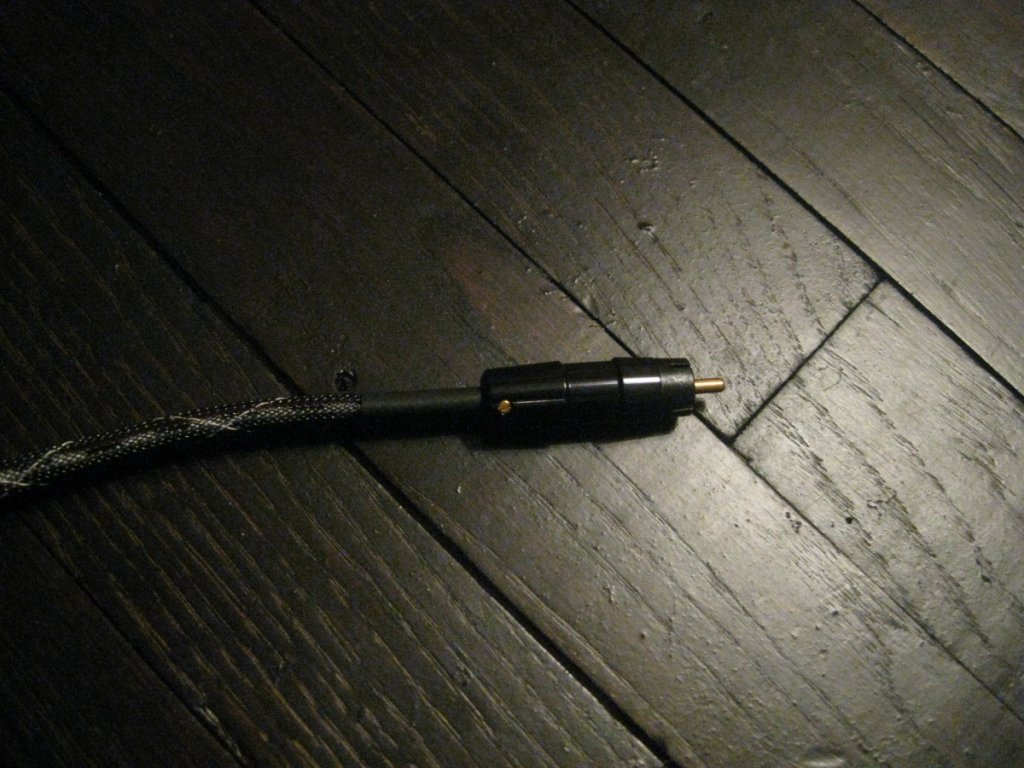

It should look like this

Attach the shell and screw tight

Secure the shell with hot glue. A special hot glue gun helps a lot here!!!

Action Shot

Ok 1 down three to go!!!

Your done