After watching Danny upgrade another Mordaunt Short model, I was motivated to upgrade mine.I'm matching the part values on the stock crossover with higher grade components. Since I own 2 pairs, my first objective is to upgrade one pair first. Eventually I'll do a true A-B comparison, determining how much the upgrades improved the speakers.

Removal of the drivers, binding post cup, I noticed the crossover is literally attached to the back of the binding post cup. The Carnival 2’s have a first order crossover. This basic crossover consist of only three components. A 3.3 ohm 7-watt sand cast resistor, a 3.9 uF 250 volt polypropylene capacitor, lastly an iron core inductor. The crossover is only 3 ¼” x 5 ½” in size approximately.

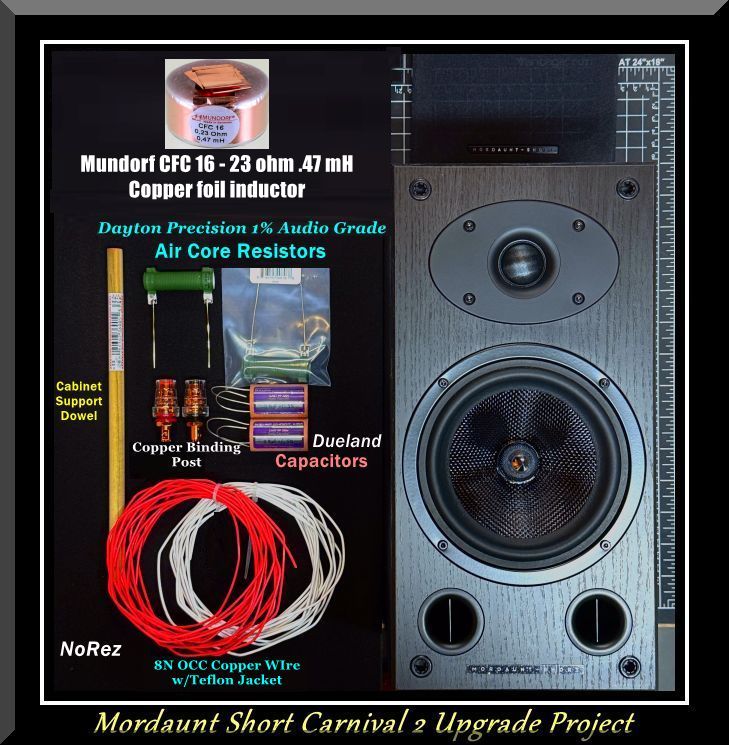

New upgraded parts consist of the following: 1.) Dayton 3.7 ohm 20 watt air core precision grade resistor - $7.99 ea.

https://www.daytonaudio.com/product/1701/dpr20-3-7-3-7-ohm-20-watt-precision-1-audio-grade-resistor2.) Duelund Capacitor 3.9uF 250Vdc CAST PP Series Metalized Polypropylene - $30.00 ea. at time of purchase

https://partsconnexion.com/duelund-capacitor-3-9uf-250vdc-cast-pp-series-metalized-polypropylene/?searchid=982721&search_query=duelund+capacitors3.) High purity OCC 8N 16 gauge copper wire, for rewiring crossover, speakers, and rear binding post. Free of charge

Note: Unfortunately, this wire is'nt available to the public, my friend provided it to me. Excellent stuff though!

4.) Simple 5/8” popular wood dowel, used as a cross brace, to tighten up cabinet resonances even more.

The dowel is very short, it only spans between the interior side walls approximately 5 ¼”. After installing the dowels, the speaker cabinet is more taunt than my NX-Studio’s. Although the speaker is tiny, dimensions are 12 9/16” H x 6 ½” W x 8 5/8” D. Spare material N/C

5.) GR-RESEARCH NoRez - 2 sheets - $34.00 ea. - $64.00 total

https://gr-research.com/product/norez-two/6.) 4PC Audiophile Pure Copper Binding Post Terminal - $17.13 at time of purchase

https://www.ebay.com/itm/1467831359627.) Mundorf CFC 16 awg air core .47 mH copper foil inductor - $34.60 ea.

https://www.madisoundspeakerstore.com/mundorf-cfc-copper-foil-inductors/mundorf-mcoil-foil-16-awg-air-core-0.47-mh/Paid $100 for the pair new, normally retail for $249.99. Factor in upgrade parts $226.31 for a total of $326.31

These upgrades have significantly improved what was a very nice sounding speaker, in it's price category, to now competing with more expensive speakers easily. I had a set of LaScala's, that never gave me the satisfaction, these have delivered dollar to performance value wise. Granted, they both are very different speakers for different applications, I get it, this isn't my first rodeo. Unfortunately, I just spent too much money, buying the Klipsch LaScala's, only to learn I don't like the signature sounds of Klipsch speaker designs.

They're way to horney sounding for me!

_______________________________________

_______________________________________

_______________________________________

_______

I’ve completed modifications to the level, I'm capable of to this point. I have a 100 hours burned in so far, and still going. Dueland capacitors require between 200-250 hours of burn in time, I've heard.

Preliminary assessment burned in at 100 hours, It goes back and forth, from midrange being forward to more laid back other times. Certain horns can be a bit more forward than to my taste, from time to time.

Even though the crossover parts are still burning in and not at their peak performance, there still is a noticeable improvement. Detail, transparency, sound stage is huge, for being in a smaller room setting, this is very impressive, to say the least. Separation between instruments is more precise. Female vocals and string instruments breathe naturally. Overall, the new parts provide improvement, I'm pleased with the results. More updates and photo's eventually.

Based on some further critical listening, I've taken some inititive adding dampening material to the port tubes. Wrapping the material around the length of outer circumference of the plastic ports, inside the speaker enclosure. The dampening material has been positioned a 1/2" away from the internal port opening though. I've also have been experienmenting with various thickness felt, placed at the internal opening of the ports as well. I've learned, port tubes being either plastic, or cardboard can resonate, with the right atteunated frequency. Polysteter fiber fill layed up against a port tube can help, but it's not as dense as using a Dynomat resonance type material, which is superior with resonance reduction. I don't feel what I'm noticing is a placebo effect. The speaker seems to have more focus, It's very subtle though. Chuffing characteristics are a non-factor, with the felt material inserted into the port tubes.

Another area I want to experiement with, is the crossover. I listened to the YT video the other day, with Danny and the gentleman with purifi. They gave me some ideas, to experiement further with my little first order crossover. Currently it's rigid mounted to the back of the terminal cup backside. Since their is so much movement internally within a speaker cabinet, I thought about rubber mount isolating the crossover. I have sorbothane material laying around, so I want to try rubber mounting the crossover board, and determine the results. I have no doubt this will minimize circuit board resonance. I figured its a simple tweak, why not.

Although the best isolation for any speaker crossover ideally, take the crossover and mount externally. Then crossover mods are real easy to do.