Thanks Hobbs for printing all of these waveguides. Is there any issue with sanding these to take some of the ridges out and painting them so that they look a little smoother?

No problem with that at all, just make sure the primer/paint is suitable for plastics like PLA.

You've got me very curious about the relative performance of this new waveguide.

How does the 3D printed geometry measure compared to the waveguides cut into the baffles, e.g. the Studio? It looks visually more "sophisticated" in the surface lofting.

I'm particularly interested in anything that helps the system sound good from many listening angles.

Cheers, and congrats on the new addition to the NX line!

D.

P.S. Being able to cross as low as 1 khz is pretty remarkable!

The waveguide was based on a series of iterations I did, with the main goal of trying to keep them within the parameters of the old BG faceplates.

Danny's NX-Treme waveguide has a custom left/right sides that are similar to what I ended up designing in the end, as it allows for a smoother horizontal off-axis response than the standard NX waveguide, which has a bit more of a stair-stepped response.

they're a bit hard to compare directly tho, as the standard NX waveguide is also about 1.35" deep, and the NX-Bravo is only 0.8725" deep, though I could technically make it as deep as 1" with minimal adjustments which will boost the bottom end even more, but I haven't printed one out to compare it just yet.

the Standard NX was also designed around OB use so its design needs to be different than the new one which is centered around the more sealed-backed design.

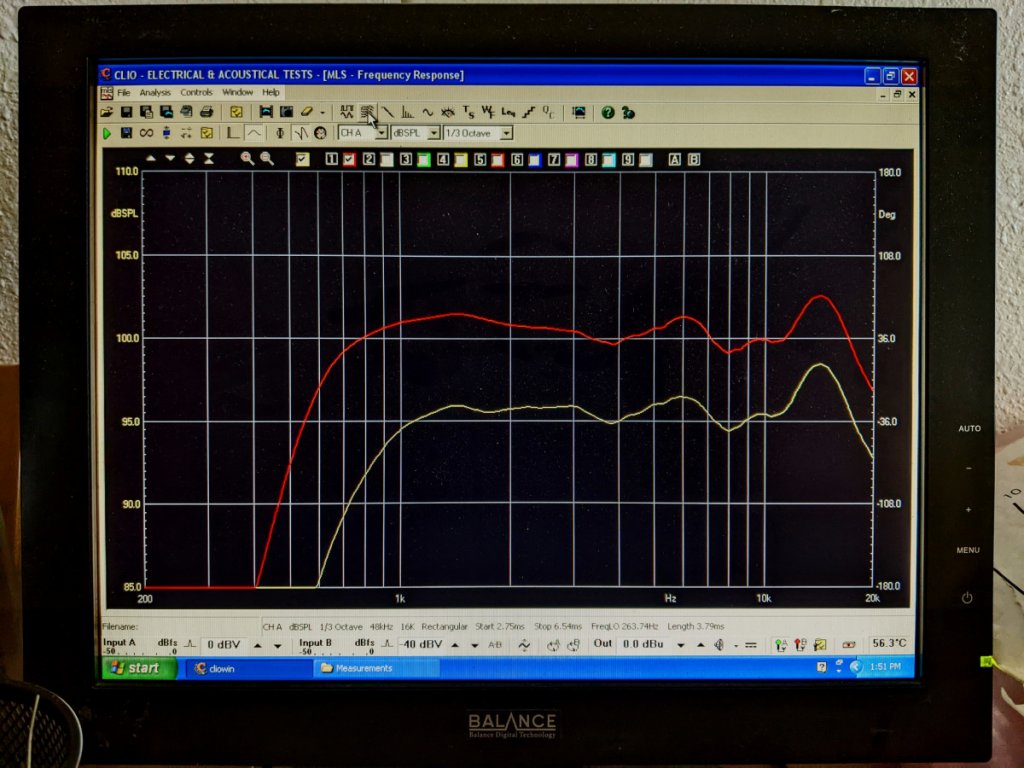

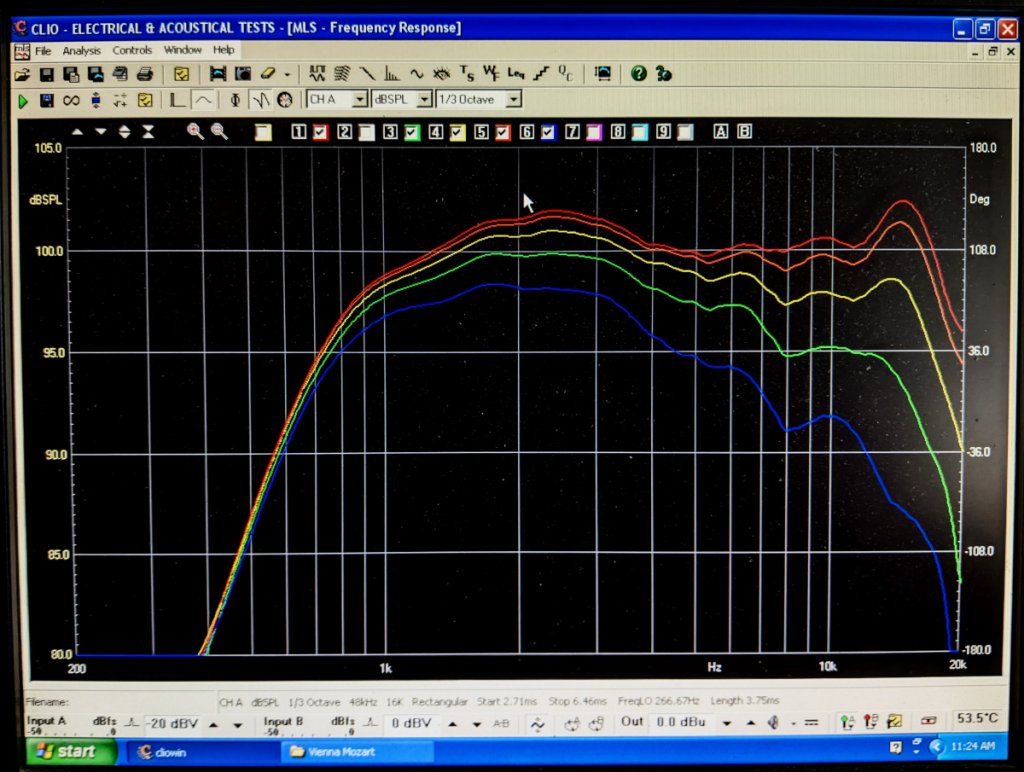

Another thing to consider is wall thickness. The first tests of the NX-Bravo were done with a waveguide using 4-layer thick walls.

Bumping that up to 8 layers increased the bottom end output a bit, allowing for me to make use of the additional extension.

A 2-wall version would likely suffer down low a bit as some of that lower frequencies will end up passing through the thinner walls and interacting with the 40% infill.

A fully solid version would likely boost the bottom end a little further but it would take forever to print and use up a fair bit more filament.

you can see similar results in the different measurements Danny showed in the initial video between the thin-walled 3" deep plastic horn and the 3" deep MDF horn, with the MDF was smoother overall with better bottom end extension. had the plastic version used thicker walls it would have been more similar to the MDF version.

PLA

vs MDF