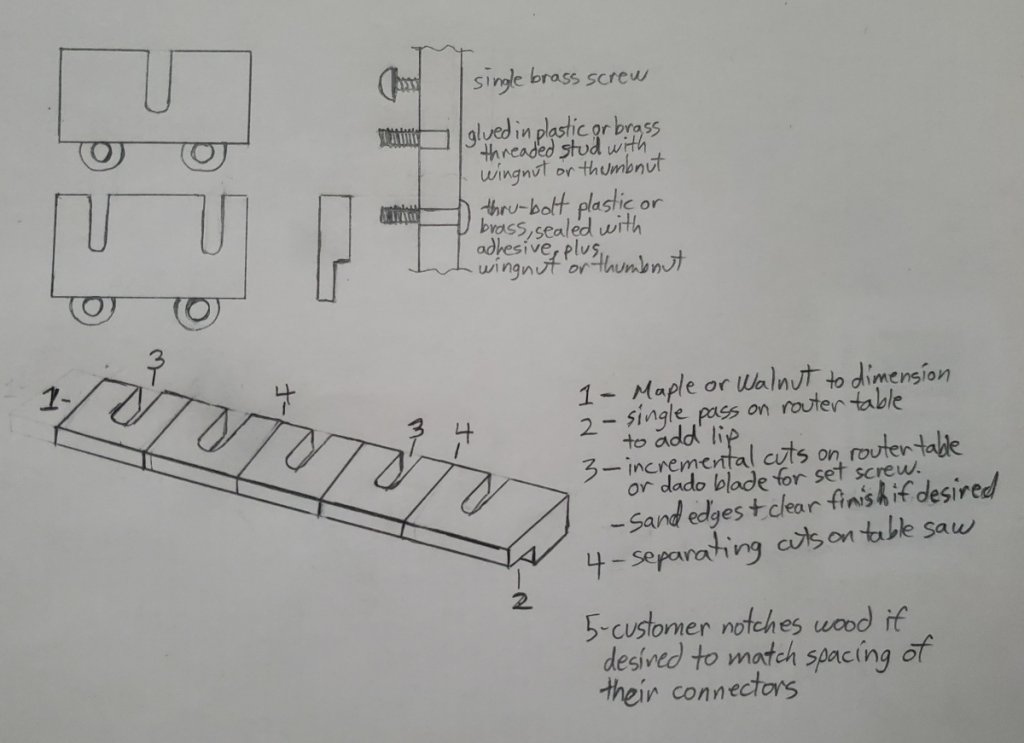

Ugh. Typed up my response than accidently backed out trying to attach photo and now starting over. I'm such a rookie sometimes. Here's drawing first.

My first thought was that I could get this sliding clip printed up and available to people pretty easily but then I remembered how little I enjoy the look and texture of cheaply printed 3d items, which leaves option of more expensive printing or hand finishing, adding time and money.

My alternate proposal is to cut these from hard wood, maple or walnut. I know it's my own bias, but if I were going to add this item potentially to a pair of $1000 speakers, clear stained maple or walnut is a much richer look than the texture of 3d filament.

I was tempted to draw this digitally in sketchup hoping someone might be impressed but I didn't want to kick my daughter off the computer and of course paper is faster so hopefully you can read my handwriting. My proposed prototype would be using only a single centered screw slot for tightening to the cabinet. With the sliding lock dropping down from above and resting against the male tube connectors, a single screw adjustment is plenty and easier to adjust than dual screws. If I were to cut these and make them available I would supply them with a single brass screw, maybe I can find one with a thumbnut type of head so no tool needed to adjust, but of course the installer could use higher end methods such as imbedding a single threaded stud if desired. I'd leave the contact edge flat which would still engage with the post and secure it without any concern for spacing. The installer however could notch for the posts at their specific spacing if they wanted it to nest deeper.

An almost imperceptible slight bevel or arch on the back edge that rests against the cabinet, slightly thicker away from the tube connectors and slightly thinner against the posts, would allow for auto adjustment to any small variation in mounting depths of the female connectors. The thickest edge away from the connectors would act as a fulcrum and the screw would give that slight tension to hold it in place, very little force is needed. Gravity holds the sliding clip against the binding posts and the single screw is just enough resistance to keep the adaptors from backing out unintentionally. Ideally, the screw would be adjusted to the point that with the tube connectors in place the sliding clip would barely have friction against the connectors and it would manually slide up and down over the connectors as needed and the screw would never need to be touched or adjusted. A thumb swipe up against the clip slides it up as needed to release or insert the posts. And there would be no change of the screw ever needed after the initial install, so a simple round-head brass screw or nut would be plenty and unintrusive. It's also far enough from the connectors I doubt there is any real concern for it to cause interference.

This is all very doable and not complicated. The benefit of group think. Im not sure how broadspread the desire would be. Maybe 5 people would want to add something like this, maybe 50, who knows? Id be willing to make some up if needed or I'd be willing to determine some precise dimensions if someone else wanted to take the lead and make some. Im open to just about anything. Whoever makes these up would truly be doing so as a service. Even someone paying a few dollars of cost plus a few dollars of shipping, there's no money to be made, but if there's enough interest and nobody else volunteers I'm willing to make them available.

Elon.

ezeescrossovers.com