Small update!

Done with tone coats! Now onto preparing the rest of the speaker!

I used wood filler to help hide the edges of the veneer, and fixed some small dings caused from frequently handling them for the tone coats, sanding, etc.

Used de-waxed shellac as recommended by others to help seal the MDF, tho the edges were far too absorbant, even after several coats. So I switched to a latex-based sealing primer for those sections, which has worked really well!

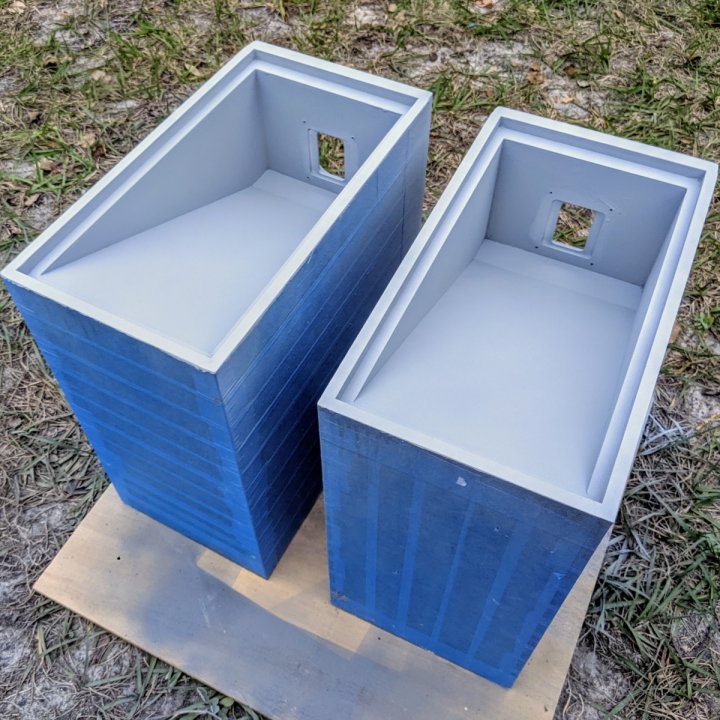

And how they're in the process of being primed!

Hopefully tomorrow I can do a little sanding, and start the painting process!