Could you clarify "feathering". If I'm imagining this right, it sounds like a misalignment or maybe cutter run-out. Perhaps plunge mechanism or pivot pin deflection.

The clamp problem doesn't surprise me. Much of Harbor Freight stuff is knocked off from existing designs but misses the mark in some small but critical details. In some cases it's of no concern, others it's apparent why it cost less when one goes to use the product.

I am definitely careful about buying Hf stuff. Some of their stuff is pretty good. Other is in between or low in usefulness. The clamps are OK if not over taxed, which is not to hard to do...

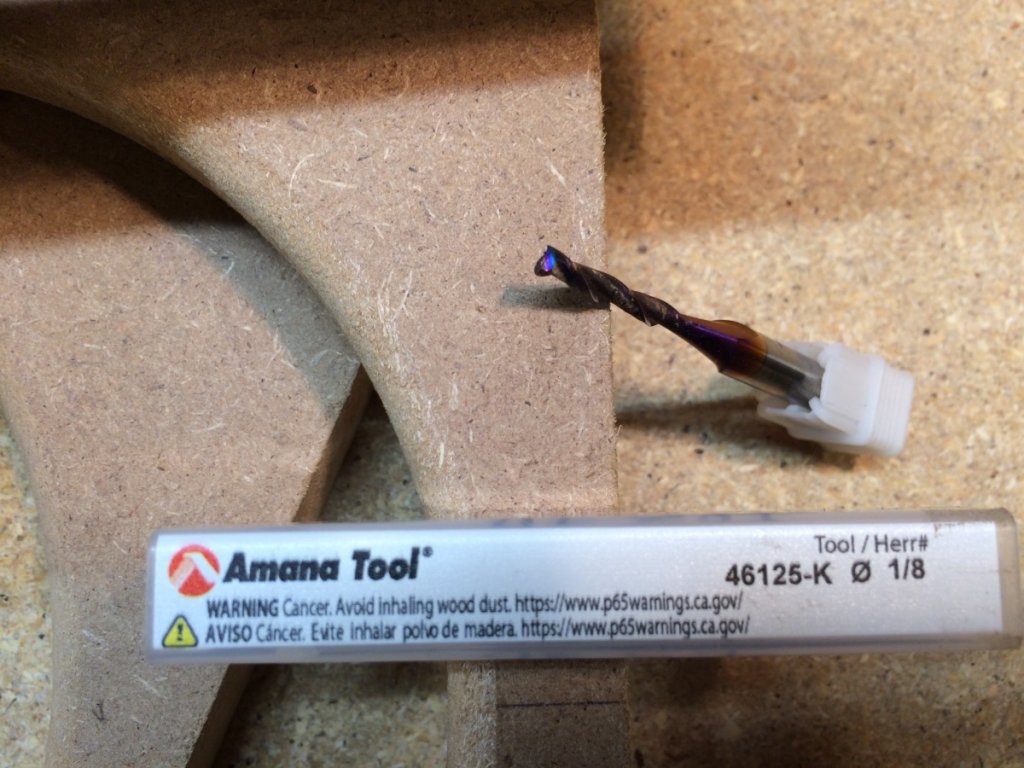

I am using a 1/8” diameter up spiral cutter

The coloring of the cutter is a coating or treatment Amana puts on; it is not from being overheated...

I do the hole cut in 2 steps just to be easier on the router and cutter. It can be made in one step; I just prefer not to. I cut to just under 3/4”, total, hence the ragged edge on the cut out piece which is remove by it being tapped out by hand. That way I don’t have to fixture the cut out piece to keep it from moving while cutting.

The first cut is at about 1/2” depth which is to one stop up on the router plunge base. The second cut is to the full planned depth. You can see in the picture of the brace piece the line between the one cut and the second. On a sample of the cut-out piece the line is hardly visible.

Note the cutout piece is upside down relative to the brace piece that is under it.

The feathering is at the intersection between the 2 cuts. I believe that feathering is caused by the sharp end of the cutter being a bit ragged on the MDF I have. I couldn’t get a good closeup of the end of the cutter, but it is shaped with 2 points and the 2 cutting edges are angled inward and downward, towards the grip end, so it makes a “V” at the end of the cutter.

As for the line. There is a slight step inward (maybe 1/64”, but have not tried to measure it) at the top of the second cut. I am guessing... The cutter is flexing/bending slightly outward at its end, due to the rotation and cutting direction. I am cutting the hole in the clockwise direction. The cutter is spinning in the clockwise direction. With this, there is a net force radially outward on the cutter. Hence my thought the cutter is flexing outward. This probably would not be seen with a 1/4” dia cutter.

Guessing again, there is no line (or little line) on the piece that is cut out because the second pass of the cutter is far enough down that there is minimal flex at the location of the line and it is “cleaned” up in the process.

I should point out that I cut all of the panels (baffles) out of the full sheet of MDF using the same brand, 1/8” cutter, that was a down cut spiral. I believe I got a good perpendicular cut. I did all of those as a single, full thickness cut. Maybe there is something is the way the end of the cutter is grabbing the MDF on a partial thickness cut that is causing it to go off line a little. This, again, is a guess.