Tech Notes

An Exacting Energiser

A little backgroundThe Pro series iESL is the best way of driving electrostatic headphones. We are confident that the iESL Pro driven by either the iCAN Pro or your existing amplifier can go toe-to-toe with the best amplifiers out there for electrostatic headphones. Its defining characteristic is a transparency and an ultra-wide dynamic range that is totally natural.

What is an electrostatic headphone amplifier and why do I want one?We have quoted from Wikipedia:

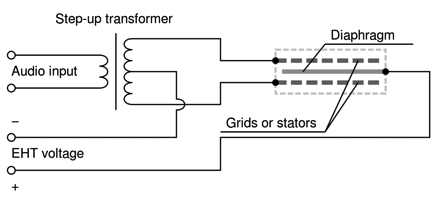

ELECTROSTATIC DRIVERS CONSIST OF A THIN, ELECTRICALLY CHARGED DIAPHRAGM, TYPICALLY A COATED PET FILM MEMBRANE, SUSPENDED BETWEEN TWO PERFORATED METAL PLATES (ELECTRODES). THE ELECTRICAL SOUND SIGNAL IS APPLIED TO THE ELECTRODES CREATING AN ELECTRICAL FIELD; DEPENDING ON THE POLARITY OF THIS FIELD, THE DIAPHRAGM IS DRAWN TOWARDS ONE OF THE PLATES. AIR IS FORCED THROUGH THE PERFORATIONS; COMBINED WITH A CONTINUOUSLY CHANGING ELECTRICAL SIGNAL DRIVING THE MEMBRANE, A SOUND WAVE IS GENERATED. ELECTROSTATIC HEADPHONES ARE USUALLY MORE EXPENSIVE THAN MOVING-COIL ONES, AND ARE COMPARATIVELY UNCOMMON. IN ADDITION, A SPECIAL AMPLIFIER IS REQUIRED TO AMPLIFY THE SIGNAL TO DEFLECT THE MEMBRANE, WHICH OFTEN REQUIRES ELECTRICAL POTENTIALS IN THE RANGE OF 100 TO 1000 VOLTS.

DUE TO THE EXTREMELY THIN AND LIGHT DIAPHRAGM MEMBRANE, OFTEN ONLY A FEW MICROMETERS THICK, AND THE COMPLETE ABSENCE OF MOVING METALWORK, THE FREQUENCY RESPONSE OF ELECTROSTATIC HEADPHONES USUALLY EXTENDS WELL ABOVE THE AUDIBLE LIMIT OF APPROXIMATELY 20 KHZ. THE HIGH FREQUENCY RESPONSE MEANS THAT THE LOW MID-BAND DISTORTION LEVEL IS MAINTAINED TO THE TOP OF THE AUDIBLE FREQUENCY BAND, WHICH IS GENERALLY NOT THE CASE WITH MOVING COIL DRIVERS. ALSO, THE FREQUENCY RESPONSE ‘PEAK’ REGULARLY SEEN IN THE HIGH FREQUENCY REGION WITH MOVING COIL DRIVERS IS ABSENT. WELL-DESIGNED ELECTROSTATIC HEADPHONES CAN PRODUCE SIGNIFICANTLY BETTER SOUND QUALITY THAN OTHER TYPES.

ELECTROSTATIC HEADPHONES REQUIRE A VOLTAGE SOURCE GENERATING 100 V TO OVER 1 KV, AND ARE ON THE USER'S HEAD. THEY DO NOT NEED TO DELIVER SIGNIFICANT ELECTRICAL CURRENT, WHICH LIMITS THE ELECTRICAL HAZARD TO THE WEARER IN CASE OF FAULT.

https://en.wikipedia.org/wiki/Headp hones#ElectrostaticTo put this theory into perspective with some figures,

Sennheiser HD800 dynamic headphones = 102dB/1V

Typical pair of electrostatic headphones = 102dB/100V!!!

Traditional headphone amplifiers do not deliver either the EHT voltage or the required audio voltage. So a special ‘energiser’ is required to match the electrostatic headphones. Typically a maximum output of 300V is needed.This is equivalent to 300 Watt into a 300 ohm headphone load!

Hence, electrostatic headphones require:

• VERY high voltages – need 300V in an instant

• BIAS voltage – adjustable from 230V to 640V

There are two options to make such a product to ‘energise’ electrostatic headphones:

Product A: a dedicated high-voltage amplifier.

Product B: an energiser, a solution which is almost opposite to a tube amp as it converts low-voltage to high-voltage.

In the real world, few amplifiers can deliver these levels of voltage output which is why an ‘energiser’ is required to ‘charge’ electrostatic headphones. Some existing tube amplifiers (like the iFi RETRO Stereo 50) could be modified to drive electrostatic headphones directly and some solid-state high voltage amplifiers also exist, however the need for such extraordinarily high-voltages compromise the active ‘direct high-voltage’ of most amplifiers.

By comparison, an energiser can use a standard speaker amplifier or a suitably powerful headphone amplifier (> 10V into 16 ohms or > 20V into 64 ohms are needed) and use transformers to produce the high-voltage required.

The iESL is the second type of a product: an energiser. Yet the iESL is no ordinary energiser. Each one of these three-core components were developed using the best classic and latest approaches with scant regard for cost, complexity or difficulty:

• The transformer

• The bias voltage generator

• The component quality

The Transformer – the ‘sound’ of the energiser

The Transformer – the ‘sound’ of the energiserLike a good chassis in a car, a transformer makes or breaks the Energiser. This is fundamental, simply because it is almost solely responsible for the ‘sound’ of an Energiser. Ideally a transformer would have no ‘sound’ signature of its own, but simply and transparently pass on the audio signal. In reality this is a challenging mandate.

A transformer is comprised of two parts, both of which in the iESL, have been executed very much with more than a nod to the ‘money is no object’ days of classic Altec and Western Electric design, materials and workmanship.

Since the golden age of stereo in the 1950s and 1960s, the art of making great audio transformers was mostly lost when tubes fell out of favour. At AMR/iFi, we retain this arcane knowledge and wish to carry it on well into the 21st Century. First with the AMR transformers, then we went onto the output transformers in the Retro Stereo 50. Now we have moved onto the iESL ‘PPC’ transformers.

To make these transformers, we had to source the required materials and implement a classic, yesteryear method of hand-winding transformers that is almost a lost art but absolutely worth the effort.

1.1 The Core – the ‘tone’

1.1 The Core – the ‘tone’The iESL transformer core uses a mix of Mu-Metal (aka Permalloy) lamination and Grain Oriented Silicone Steel (aka GOSS). Most audio transformers for such higher levels and power restrict themselves to using steel.

https://en.wikipedia.org/wiki/Electrical_steel#Grain_orientation+ GOSS handles high signal levels well, which is needed if we wish to produce 300V or even more.

- GOSS has problems with hysteresis at low levels, causing loss of low-level detail. In some cases this ‘simplification’ of the music signal may be a desirable effect, however it is a clear and audible distortion.

Mu-Metal is a unique magnetic alloy with very different properties to GOSS:

https://en.wikipedia.org/wiki/Mu-metal+ Mu-Metal/Permalloy is great for low signal levels (low-level resolution) but cannot handle high-level signals well. Mu-Metal based transformers are well known for their crystal clear sound, but generally cannot handle high-levels, restricting them mostly to use in microphone pre-amplifiers or for moving coil LP-pickups, where signal levels are measured in thousands of a Volt, rather than hundreds of a Volt.

- Mu-Metal/Permalloy requires heat treatment after being worked (e.g. being cut) to restore its magnetic properties. It is hugely more expensive than GOSS and in limited and forever dwindling supply as existing makers close up shop or are acquired and drop less profitable, lower volume products such Mu-Metal/Permalloy from their lines.

Combining the two materials in pinstripe fashion, a process pioneered by Peerless Transformers USA in the 1950s gives the best of both materials.

Peerless Transformers featured in the legendary Western Electric and Altec (“All Technical Services”) recording equipment from the golden age of stereo.

Getting identical laminations in GOSS and Mu-Metal/Permalloy is challenging, getting ultra-thin laminations such as we prefer to use, more so and then manually and individually assembling each core with different materials in a repeatable pattern has to be done by hand. Arduous? Yes, but worth it.

1.2 The Winding – ‘Voice of the Transformer’While a good core is the key to making a transformer that has good dynamics and correct tone, the winding must be equally considered. Due to many limiting factors, making a transformer with a wide bandwidth and low distortion is very challenging.

The winding structure determines the bandwidth of transformers. Typically winding audio transformers is a compromise between low frequency cut-off, low frequency distortion and high frequency cut-off. These three elements tend to form one of the classic "choose any two" triads, especially for classic ‘layered’ construction transformers. Often transformers have a high frequency cut-off (-3dB) barely higher than 20kHz and low frequency cut-offs barely below 20Hz.

An Energiser using such transformers is likely to exhibit a muffled top end while bass is compromised by the lack of really low cut-off and excessive phase-shift in the audible range. As an absolute minimum specification, we targeted < 10Hz – 40kHz, -3dB, which is required by the JAS ‘High-Res’ logo, which we strive to earn with all our products.

To attain such performance, some rarely used techniques were employed to sidestep the ‘choose any two’ limitations for the iESL.

The key is the use of Scheibenwicklung (disk-winding)...

The Scheibenwicklung is also quite old, German patent DE861406 C issued to Siemens GMBH Jan 5, 1953 with a filing date of May 14, 1943.

(

http://google.com/patents/DE861406C?cl=ko) covers this.

Transformer Illustration from here:

http://elektronik-kurs.net/elektrotechnik/transformatoren/Transformers in the iEnergiser are unique in combining Scheibenwicklung and layered winding in a complex interleaved pattern to achieve results that considerably exceed either technique. The design of such transformers is mostly an extinct art, with virtually no text remaining (never mind in print) and few people who still have the know-how. And manufacturing of such designs is orders of magnitude more challenging than generic transformers.

Our transformers match and exceed the standards set by Siemens (Germany) and Peerless (USA). With a bandwidth of < 5Hz to > 60kHz (-3dB), transformers in the iESL far exceed the requirements of even the JAS High-Res Logo.

To recap, in order produce high-voltages required by electrostatic headphones, the Pro iESL employs custom-made Pinstripe Permalloy Core Transformer (PPCT) of the highest quality:

• Ultra-wide bandwidth signal: attains <10Hz all the way up to 60 kHz.

• Perfectly linear: from low through to high signal levels.

• The extremely critical core of the transformers is a GOSS/Mu-Metal hybrid. This reduces distortion dramatically, when compared to traditional cores, be they GOSS, amorphous iron or similar materials.

• In order to combine a high step-up ratio with good behaviour without excessive resonances or bandwidth limitations our custom transformers use a complicated multi-section winding with both vertical and horizontal sectioning. Extremely thin wire must be wound precisely and tightly to create the performance required.

Combining this complex winding with an exceptional core produces a transformer that handles ALL levels without distortion drawbacks as well as offering a completely flat frequency response without colorations well beyond the audio band.

In terms of performance, only such an exceptional transformer can approach and even exceed the best transformer-less amplifiers.

More to come.