I have been getting a lot of emails and messages about where the Russian Teflon FT-3 0.10uf 600v caps should be placed on their boards. This post is just my personal recommendations for cap placement where it achieved the greatest impact in my own system. I hope that as others experiment they will post their results in this same thread. This will be very helpful to others that want to experiment in the future.

Also, I want to thank all of you who have expressed appreciation for the group purchase. It has consumed a lot of my time and effort for the last several weeks. However I am cheap and I love a great deal. I know there are a lot of us out there that just need an easy way to evaluate teflon bypass caps to see if they fit our requirements. The group buy helps us evaluate these caps and a great overall savings. I like that!

A side benefit of the group purchase has been to get a chance to communicate with so many of you out there. This is one reason why DIY captivates me, it is the great people and their experience and perspectives that help me enjoy this hobby to the fullest. Jim Hagerman is a dream come true for a DIY afficianto. I am so glad I have built my projects just to get a chance to learn more about the inner workings of circuit design. I am better for DIY and for Jim Hagerman!

Before discussing the cap placement I should make a couple of overall comments.

First, these caps are simply parallelled with the cap value that Jim Hagerman speficied for the pcb position with just two exceptions. The incoming signal cap values for the Clarinet and Cornet 2 are identical to the 0.10uf values of the FT-3 caps. This allows you to run the teflons alone in these positions which I will discuss below.

Second, you can quickly piggy back these caps for evaluation of their improvement to your equipment. Use a vinyl tie strap to secure the FT-3 to the cap already soldered to the board.

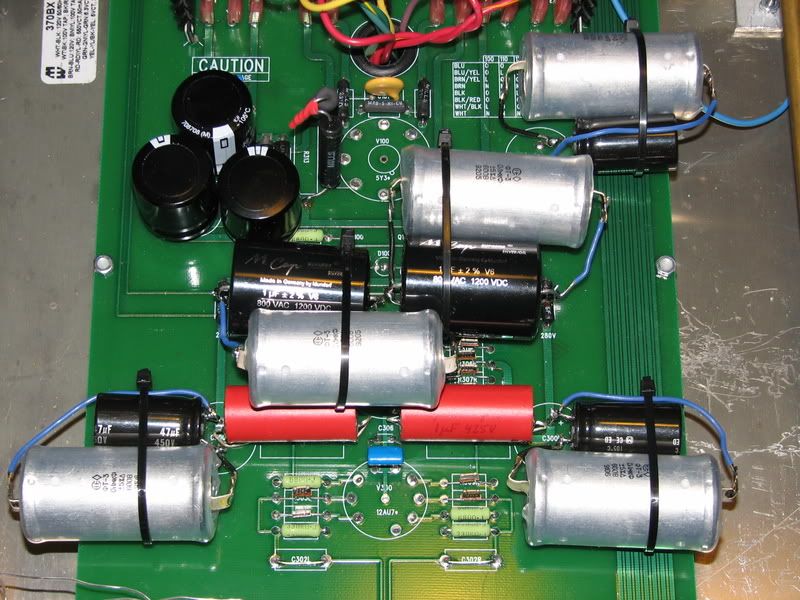

Here is a picture of my Clarinet.

BTW I no longer bypass the first 47uf B+ capacitor. It comes before the step down resistors. Now I just bypass the C301 B+ supply caps going directly to the tubes. This saves me one teflon cap from the picture you see here and sounds just the same.

Just solder a wire from the existing cap as close to the board as is easy to accomplish and then trim and solder that wire to the tie strapped FT-3 cap. This way everything is nice and snug and you can easily remove the cap should you dislike what you hear.

For permanent placement, you could consider soldering the 1.0uf value caps on one side of your pcb and the teflon cap on the other. Anumber1 recommended this to me after seeing pictures of my piggybacked teflons! I like a nice and neat case as much as the other guy. I appreciate his recommendation.

This is VERY IMPORTANT....the outer casing of the Teflon cap is conductive aluminum. You will get a nasty ground loop hum if this cap touches a ground which includes the case work. If it bridges components it could cause a short.

I would recommend purchasing some 1 1/4 inch shrink wrap and cover the caps. You could use electrical tape for short term protection. I used clear shrink on mine with excellent results. I purchased some 6 and 8 inch long vinyl tie straps from my local electronics and auto supply stores. You will need these long nylon tie straps if you want to piggyback the caps for evaluation. BTW you could leave this as a permanent mounting as well if you are not transporting your gear across country.

Now for the positions:

For the Cornet and Cornet 2 the first incoming signal cap is position C 203 right and left. These are specified as a 0.10uf value 450V component as specified by the Auricap upgrade. Simply remove what you have there and replace it with the FT-3 0.10uf 600v teflon capacitors. These are mil spec aluminum and teflon film capacitors. The Russian distributor has tested these and they function without failure to 1000 volts.

The final signal cap position is C208. These caps leave the most dramatic final sonic signature on the sound of your Cornet or Cornet 2. The teflons have improved every one of the three 1.0uf caps I have evaluated. I am confident you will benefit sound wise even if your unit has the orange drop caps.

Paralleling the cap or piggybacking as I like to call it provides an additive value to that position. You do not want to make a mistake of serially connecting these caps. This would half their value. In parallel your final uf will be 1.1uf +/- the % variance of the cap you selected.

I am confident to say that for the great majority of Cornet and Cornet 2 owners by simply removing the existing C203 cap, replacing the C203 with teflons and piggybacking the C208 position caps you will achieve 90 percent of what I gained in my system.

While you are in your case please verify the heater voltage going to your tubes and the other test point positions. Make sure they are producing addequate voltage. My C2 required lowering the H+ resistor to get the values higher for my heater voltage. This improved my bass and the overall frequency response of my C2.

For those wanting to get maximum dynamic response and bass slam, then you can consider adding teflons in parallel to the B+ supply bypass caps in positions C200 and C206.

I found that the C203 cap position was critical in my system. The teflons easily beat my Auricaps, Dynamicaps, K40Y9 PIO and Sprague Vitamin Q PIO caps I evaluated.

On the Clarinet, you can use a solo pair of teflons for the right and left C302 position. I ended up bypassing this with solid core silver wire instead of using a capacitor. Jim Hagerman put this incoming signal cap in position to provide DC protection. If your source equipment has DC offset built in, then bypassing this will be sonically rewarding. If in doubt, the teflons would be the most sonically transparent cap you could use in this position.

Next you will want to parallel the final signal cap in position C303. I also use the teflons in parallel at position C301.

I hope this helps clarify where the caps can go and where they might sound best. Again, please add to this thread as you complete the process of adding the teflons in your equipment. It will be great to have a historical perspective on teflon bypass caps.

Cheers!