Hello friends, I've been absent for a while from the forum, but I have still been performing crossover assemblies, I just wasn't logging in here at audio circle. Now that things have relaxed a little bit in my life, I'm returning to some activity in the forum.

When things were most hectic for me, I did take a few months off with no assembly work, and referred everything over to Frederick.

He also has posts here in the forum.

https://www.audiocircle.com/index.php?topic=181739.0I appreciate his willingness to step in and provide an assembly service option. Frederick and I have had many great conversations and he is worthy of your trust for any assembly needs you may have. There is zero competition between us.

What many people who are outsourcing crossover assembly work may not understand is that crossover assembly is not profitable as a business. We both spend a lot of time in labor, but also in communication, as well as shipping, that is well beyond the assembly fee that either of us charge. This truly is a labor of love. Sometimes it can be a lot of fun, but there are many tedious and stressful moments as well. Many customers are very pleasant and appreciative. Some are high-maintenance and overly concerned about every detail that may not have any impact at all, which equates to lots of hand-holding and advice, which equals lots of donated time.

I doubt it is much different for Frederick, but for myself, I have easily donated more hours than I have billed for. Not a complaint, just a reality. I love problem solving. I love the challenge of creating a layout for a difficult design. I love encouraging and helping people in this hobby. Charging $120 or even $200 for an assembly job is not enough to create a financial motivation, but it allows me to take my family to dinner occasionally or treat them to something as thanks for all the hours I was unavailable to them and busy on assemblies, emails, and phone calls helping DIY'ers.

I'll create a new Thread to have some discussion and share some things I've learned throughout this process, but since this thread is a sticky, I'm staying brief and will leave topics for back and forth discussion in individual threads.

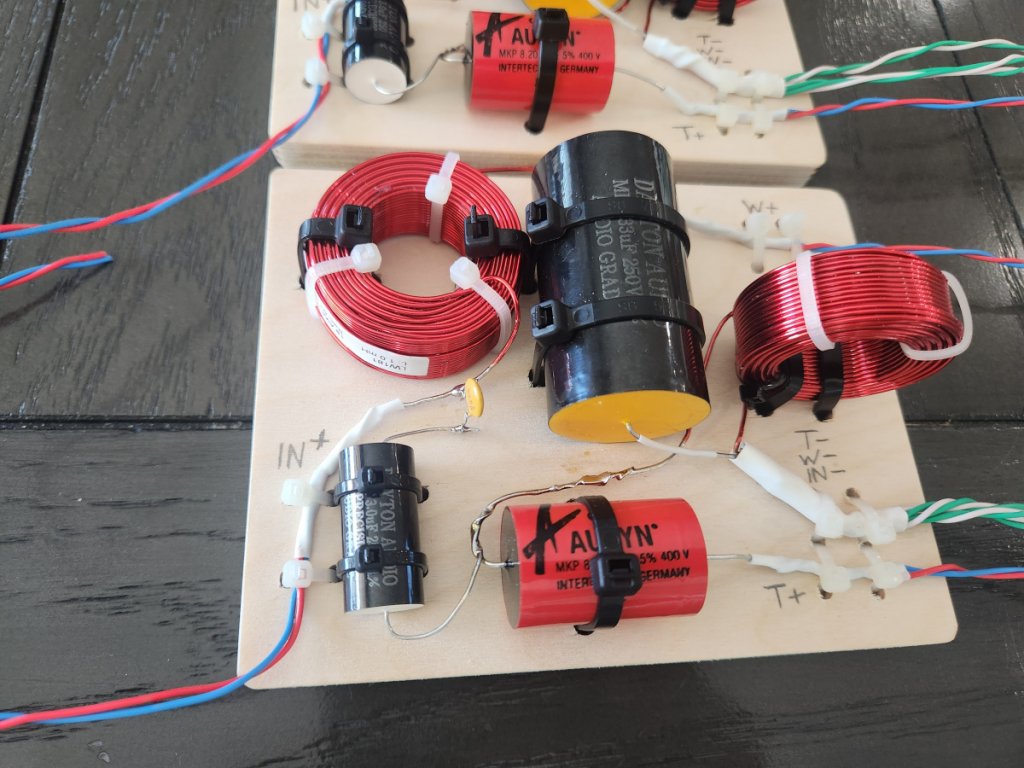

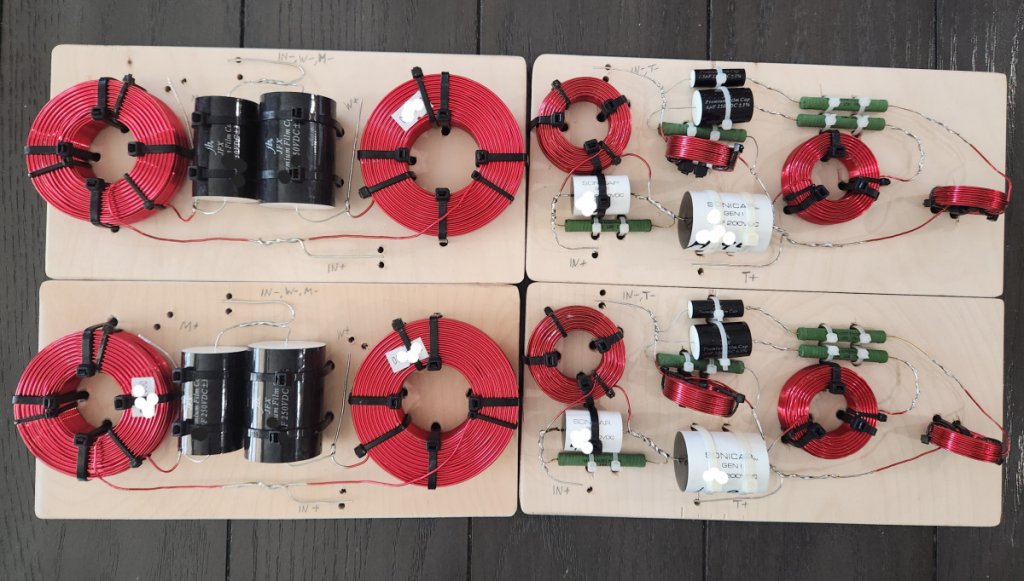

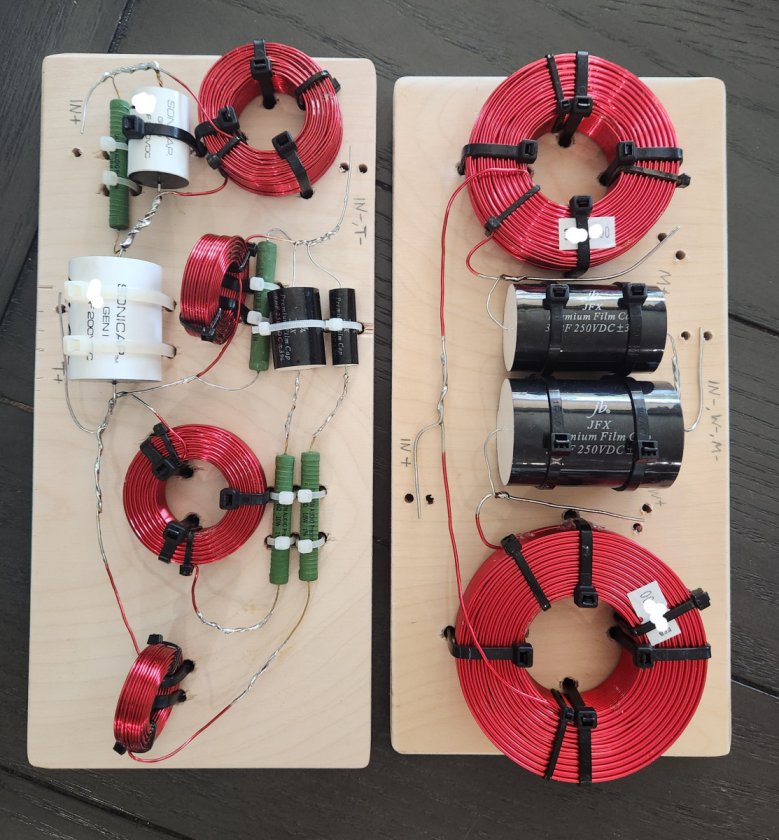

A few recent posts here have shown interest in the Klipsch RF7 series upgrades so I'll post a few pictures here. The RF7 series is easily one of my favorite options for a large tower, and the crossover redesign from GR-Research really does a fantastic job of improving its shortcomings and maximizing its potential. I don't have room for towers at this moment, but if so, my first two picks for today would be the GR-research updated RF7III, or the GR-Research X-Statics. Maybe another day I could feel differently, but currently those would be my two choices for my space.

Rf-7 iii above in photos. Followed by a few other recent assemblies below. The ones below are not GR-Research designs. They are either upgraded parts on original layouts or possibly published designs, and just there showing layout and assembly styles.