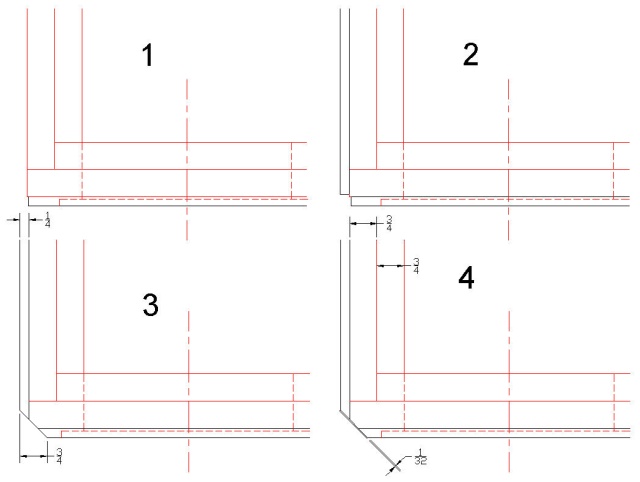

Thank you for the tips Hank. Sorry, but I have a couple questions on the instructions you listed. First I need to explain my plan a bit. Below is a picture of what I’m planning for the box design. The red lines are the MDF, the black lines represent the ¼” birch-veneered plywood. That’s right, pre-veneered plywood, I don’t want to try and tackle doing my own veneering on a box this large.

Section 1 shows the front baffle, with the layer of ¼” plywood glued on, speaker holes all in and recessed; this complete front baffle glued to the side wall(s). My plan is to make up this basically complete front baffle before I glue it onto the enclosure. That way if I screw up the front baffle I don’t have to get the chainsaw out again.

Section 2 shows the side layer of ¼” plywood glued on. You can see how it overlaps the side edge of the front panel MDF. You can also see that I show the ¼” plywood not running all the way to the edges, don’t need to…

Section 3 shows a ¾” x ¾” chamfer cut along the vertical edge(s). I plan on going with the bigger chamfer to compensate for the slightly wider box. That way the flat part of the front baffle will be the same width as called for in Danny’s design.

Section 4 shows where I plan on laying a strip of material on the chamfered face(s). It’ll be about 1” wide. Not exactly sure what I’ll put on there yet. I may go with a strip of brushed aluminum or Stainless. Not sure how I’d attach that however (maybe epoxy).

There it is… for the front driver holes I plan on cutting the inner panel holes with a jig saw slightly undersized (to me cleaned up later). Then, gluing the inner MDF, outer MDF and plywood together. Then cutting the recess, then my driver holes from the front with the Jasper jig & router.

Hank, sounds like you used a 1 ¼” rabbet bit (without a bearing I presume) for cutting the recess. I guess I’m a little nervous about how close those holes are to one another and having the router breakout a thin section of wood. That is why I had asked if might be better cut the recess with a spiral down cut bit and then the holes with a straight bit. You’re the pro, I’d love whatever feedback you (or anyone else) may care to offer.

Jon

PS Funny side story… A couple days ago I told my wife I had posted a picture of my sawed up cabinets in a thread on this forum. I shot her the link and she got a chuckle out of it.

Zoom ahead to today and after work today we hopped in the car together to go up North to visit her Grandma and the first thing she says is, “so… where do you think you’re going to get the money for this ‘cross-over upgrade’ you’re talking about with Danny and your internet friends.”

YIKES! You know, its nice to be able to share your interests with your spouse but this is getting too close for comfort.

Big brother is watching (and you thought the moderators kept things on a short leash).

A female has entered our midst and its my fault.

Everyone say hi to Tammy!

BTW, she hates these Emoticons...