Hey everyone, I figured it was about time to make a post on my triple servo subs build. As I've mentioned in previous posts I'm building 2 sets of these.

All of the 3/4" and 1/2" MDF cut to rough size to be laminated for constructing the cabinets.

Some of the panels in glue up. (I made a post about laminating sheet goods if you're curious about that)

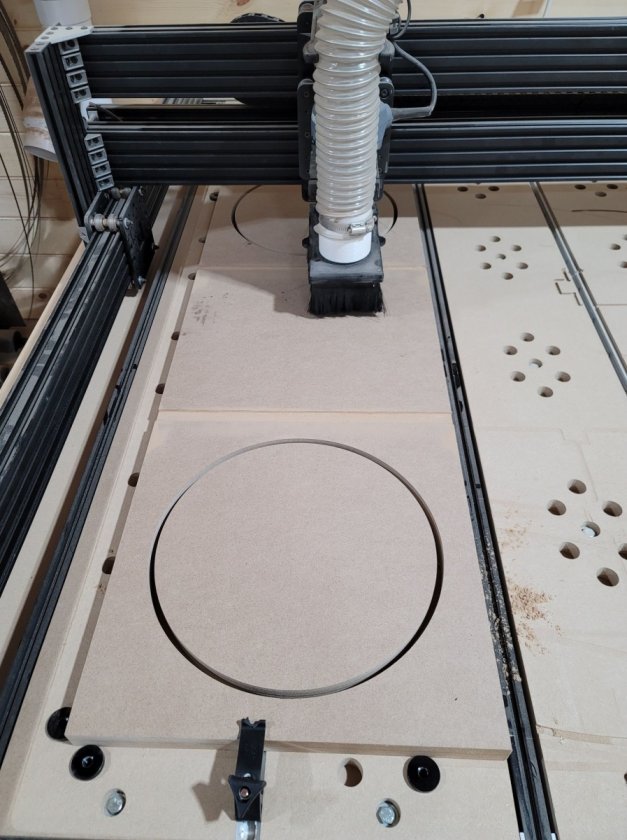

One of the baffles being cut on the CNC. My CNC is an openbuilds Lead 1515 and has an area approximately 4'x4' - not nearly as big or heavy duty as Jay's, but it gets the job done!

One of the side panels on the CNC. I played around with the dimensions for the dado's to get a perfect fit. All rabbets were done on the tablesaw because it's faster than my CNC.

First one in the clamps.

I thought it would be smarter to paint the insides first, then sand up any overspray and then apply the veneer. I think this is the wrong order. Latex paint is sticky, and sawdust in my shop sticks to it like crazy. I'll have to respray the first 2. The 2nd pair of cabinets I veneered first - then I'll carefully mask everything off and shoot the paint.

Part of the veneering process. I'm using Heatlock glue. You apply the glue to the cabinet and the laminate - let dry, and then iron on. Make sure the glue is COMPLETELY dry. On one of my pieces the glue was about 99% dry and I was tired of waiting. The stuff acted exactly like contact cement. I couldn't reposition or remove it. I ended up peeling the entire piece off, ripping away a very fine layer of MDF in the process. The next day I spent about 3 hours carefully using a heat gun and scraper on the back of the veneer to remove the glue and sanded the cabinet again before trying again. Don't make my mistake!

First cabinet veneered. 3 more to go, along with careful trimming and sanding. As you can see I cut the top (and bottom) with the little strip that covers the top front edge and bottom front edge out of one piece of veneer so that the grain is matched and is continuous. I also veneered the tops and bottoms first, then the sides and front. That way the little bit of glue line and "edge" of the veneer is not visible from the front.

All of the cabinets veneered and the first coat of finish on. I'm using Rubio Monocoat - which is a finish I love on my furniture. Technically it only needs one coat (hence the name), but I find it gives a bit nicer finish if you apply a 2nd light coat.

Next, all of them will get the interior painted. As you can tell from the front rabbet running around the perimeter, these will be getting grills. I'm debating over cutting the grills on the CNC, which yields a lot of waste MDF and also MDF is so weak - or making them out of hardwood.

One of the sets will also be getting a stand which will raise the speakers up about 12" to accommodate the drop in my theater/listening room which has steps. The subs will be on a floor which is 2 steps, and 12", lower than the listening position. The stand will also house the amp. I'm thinking I may partition off the rest of the base from the amp and fill the remaining cavity with sand.