Morning! Hoping to finish these today! I have to wire, install and line with no res. It’s possible!

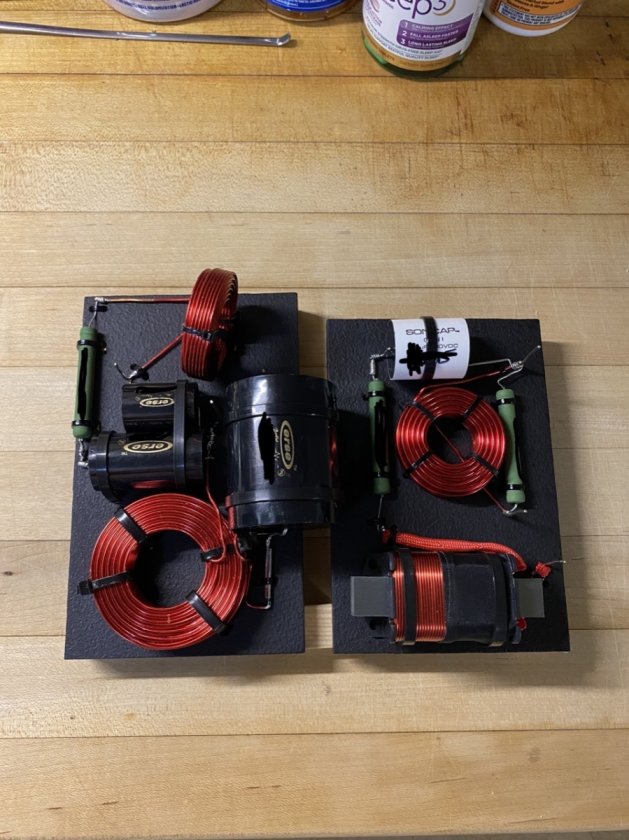

Photos below. Again, I know a few people have been looking for a examples. Your more then welcome to use these.

Why did I not stack? Hight in the box is very small!! Remember when cutting these boards out, you have to fit them through a 6” hole! Granted you can, if you know how flip and spin the board in the cabinet. But, to me... The worst idea you could have is placing anything in a “gravity pull” type of situation.

Shivers... WTF?

Gravity pulls down correct? So, most of you should lay these on the bottom, where you want your network placed. Not the side, not the top! (If.....if you can prevent this) Why!? What goes up, must come down. Over time, heat and vibrations of you have not 100% secured the network up in place, you’ve got a HUGE chance of it falling down, and slamming the bottom. NO NO NO.

That will just bring on the vibration, and cause issues we don’t want. All this work you are doing... don’t want it to go to hell over a architectural building snafu.

Combined the boards weighi just over 2.6 pounds. That’s some weight to fall! So, I tried to make these compact, and make sense. Split the coils up, normally I would want to keep as many away from the tweeter circuit as possible!

Why? I think the high end circuit is more prone to audible noise. So, being it’s more easy to hear the higher stuff then the lower stuff.. I try and make sure they are split and away. Again, I could have split the networks to three, not combining the woofer inductor, but due to space.. as well main important factor... Your wire you have is limited. If you think about it. Woofers in parallel thats 4 feet of wire right there. Mid and tweeter. Another 4ft. At 8 feet before tube connectors and the wire running outside the box to the drivers in order to solder. Your connection side. I’m a little worried. First site I thought I was ok.. till I looked at the diagram, then amount of space I could use.

I feel it’s important to take these apart and figure your space out before you cut your network boards.

Heat shrink I still feel we should get 12 inch of red and 12 of white. Counting connections like last time And I factor 1 inch for covering. Between drivers and network that’s 16 connections. Not including tube connectors. You may want to drop to 3/4 of an inch, good luck with that covering the full area that’s exposed. I’ve found 1 inch is good, your findings maybe different. That’s cool! .

Heat shrink is cheep cheep. Before you start, go to the hardware store, or order some from Amazon if your not at that point. Just get your self some white and red. I purchased a full box or assorted shrinks, as well they have a heat glue which helps seal that connection. It’s not needed.. but I like it. Again, it’s just heat shrink.. no big deal to grab some on your own.

These are just tips for anyone looking to tackle this. If you don’t need the advise, kindly pass on.. Other wise I’m sure some will be happy to see a reference to this network. I’ve seen some of you ask, and some of you post looking for an examples.

Here you go! Let’s see if you can follow the circuit. Largest is the mid, then next will be tweeter... from that the woofers have one inductor.

I chose my main board 4x6.5 and the secondary board was 4x6. I could have shrunk this down more, but I chose not to. I wanted extra space to wire and “nail down” the wires for the woofers. This way I have some strain relief! Don’t want these super tight where things will break.

Think for a second, you may want to pull the drivers back out to try... Fiber glass.. or maybe you had an issue! While your putting it together, consider you may take it back apart! This is why it’s good to leave slack and h ability to move, yet having those important wires locked in place not to pull out of the side of say that big inductor.

Just tips. But you can ignore everything I’m

Saying, do it your way!! Again, this is just some kind advise for folks that want to tackle this job, yet may need a photo or a question answered.

PS, if you in fact have someone help you build these, and they show you the progress... words you should not say while you have someone else building these for you..

“Wow, That looks easy”

“That’s all there is?”

“Anyone can do that”

“I can build that in 1 hour” no... no you can’t.

“Your just cutting wire and pasting into place, how difficult can this be?”

Well, it’s not hard.. very time consuming. It can be insulting to hear those comments. Lol. But I get it, this just looks like some parts on a board.

Is it easy? It’s not rocket science. But it’s a step on the way to that science! Lol. So, take caution! Or you will get something to blow up, like a rocket!

Anyone can do that... Then why am I? Lololol

Soldering is a ton of fun! Anyone who’s soldered with regular tin mix, and then silver will see a huge difference. If your using an iron, set that as hot as you can! I run mine at 800 deg.

This will allow you to be in contact for a short amount of time. You don’t want to over heat things. Look closely, and make sure you soldered it all!

Cold solder joints..

This is like the wolf in sheep’s clothing! Everything looks normal, but you have a connection that’s not complete! Needs more heat and reflowed solder. Keep an eye out for these!

Friends, the network is the most important part to this upgrade. Pay the most time and attention to it. No res and such.. well you can screw that up without costing you potentially a ton of money by blowing stuff up. Most amps have a protection mode, but anyone in the field will see these devices fail, and well your AVR can go way-side.

Double, Tripple, quadruple check your wires, connections, soldiering! Don’t use the solder to bridge gaps!! That’s a no no. Do your best to twist, and or making sure your contact points are solid.

Next up, cleaning the cabinet. The glue they use almost looks like a fiberglass resin. Almost.. it’s a green glue or some sort. Your gonna want to clean the walls, and wipe it down before applying your no res. Photos of this to come.

If someone wants to see something done, or a video please fee free to ask. I truly hope these help, that’s all I’m going for!