Some more progress...Christmas is looming near!

Getting driver cutouts done and making grills

I made templates for drivers, template hole is 3/32" larger than actual cutout...you'll see why.

Here's the tweeter jig for RS, upside down

From beneath, sitting on RS

Here's top view, I used a screw to temporarily fasten to cabinet, hole is within the woofer cutout

Tweeter flange cut

Tweeter through-hole, same bit, different template guide

Notches for connectors...and a mistake...can you spot it?

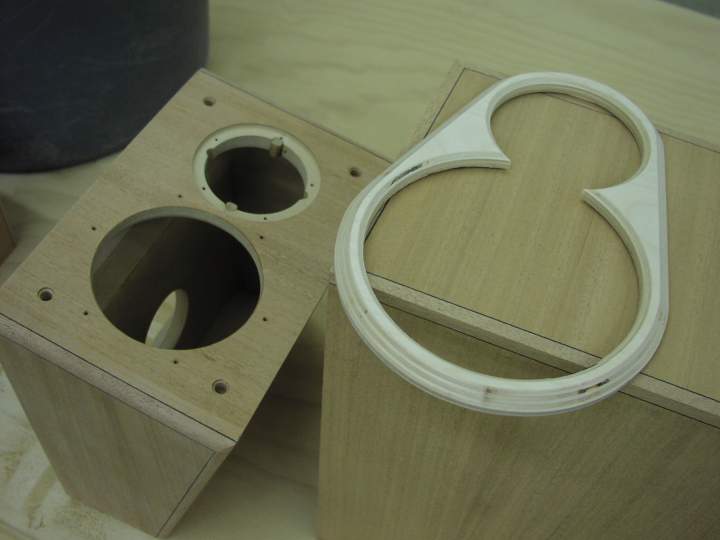

I got indicisive on grill design, three iterations to get where I wanted, good thing I like woodworking, huh?

Here's the first go, 1/4" material, built up perimeter. Need 1/2" clearance off cabinet surface to accomodate woofer height

Second brainstorm, 1/2" material, different design

Changed my mind and went to something more squared off, just didn't like the way the roundy one looked. 1/2" material, I'm recessing back for staples and mounting clip flange.

Front & back

Using grill as guide for drilling cabinet holes for sockets

And the clips, different then I've used before, I think I like them

If these were for me, I'd have recessed magnets, but I'm thinkin' the magnetic grills would become a curiousity for inquisitive grandsons and squashing the tweeter dome would be next in line. What is it about domes and kids?