As discussed in the YouTube channel comments, I have found time to draft a transmission line design for the LGK 2.0 full range driver. To do this I developed a process using Excel for the packaging and David McBean's HornResp software for the analysis. To give an idea about how much effort went in, the iterations were as follows:

0. Use LGK 2.0 reflex as starting point.

1. Front port vertical folded TL (as PMC ATL designs).

2. Front port horizontal folded TL.

3. Front port reflex (lower tuning).

4. Rear port folded tapered TL (as Martin King designs).

5. Rear port vertical baffle TL.

6. Final reflex transmission line RTL hybrid.

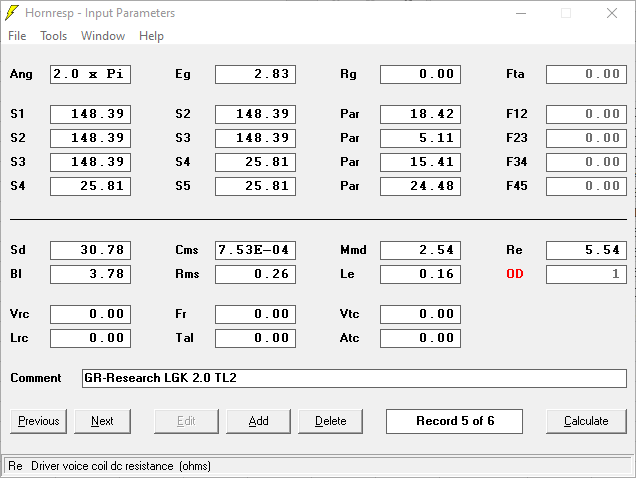

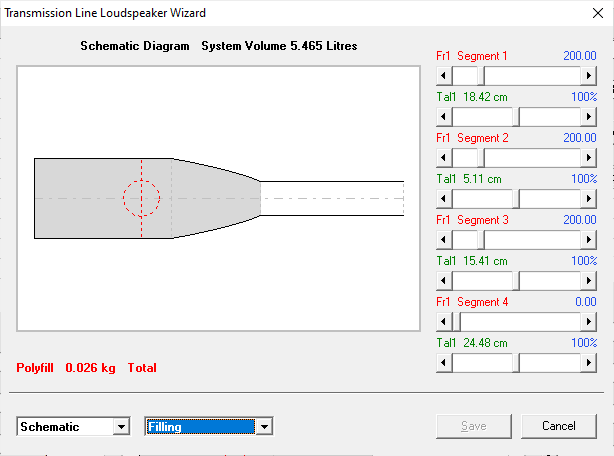

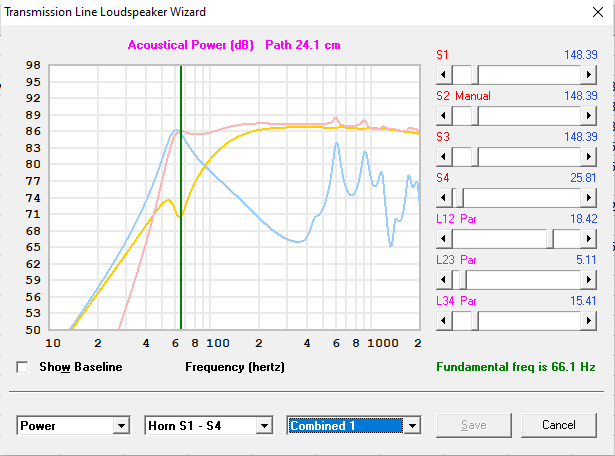

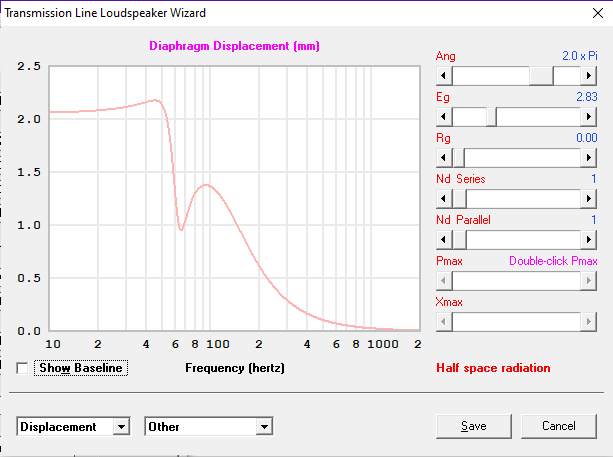

So, the model I built for the existing LGK 2.0 showed a cabinet mode of 78Hz, with some minor midrange modes. I wanted to improve the power handling below this, so decided to tease out the 1/4 wave mode to 66Hz (0.25 octave lower). Do I recall correctly that the latest LGK 2.0 drivers can handle 2mm xmax? The switch from front port to rear port was because I found that the extra time delay helped with some midrange phase cancellations from the TL output. The 3/4 wave mode is cancelled by careful driver positioning, and the 5/4 wave mode is cancelled by putting the vertical baffle 1/4 wave behind the driver at this frequency. Hornresp overpredicts modes above this as the 1D horn assumption no longer applies. The real advantage of transmission line over reflex is that you can critically damp the 1/4 wave mode to tease out the bass without too lumpy a response before roll-off (I was aiming for a 1.5dB corridor with gentle LF roll-off). The corner pieces and radiused edges are just there to improve the aerodynamics and to make sure that no unwanted reflex modes sneak in.

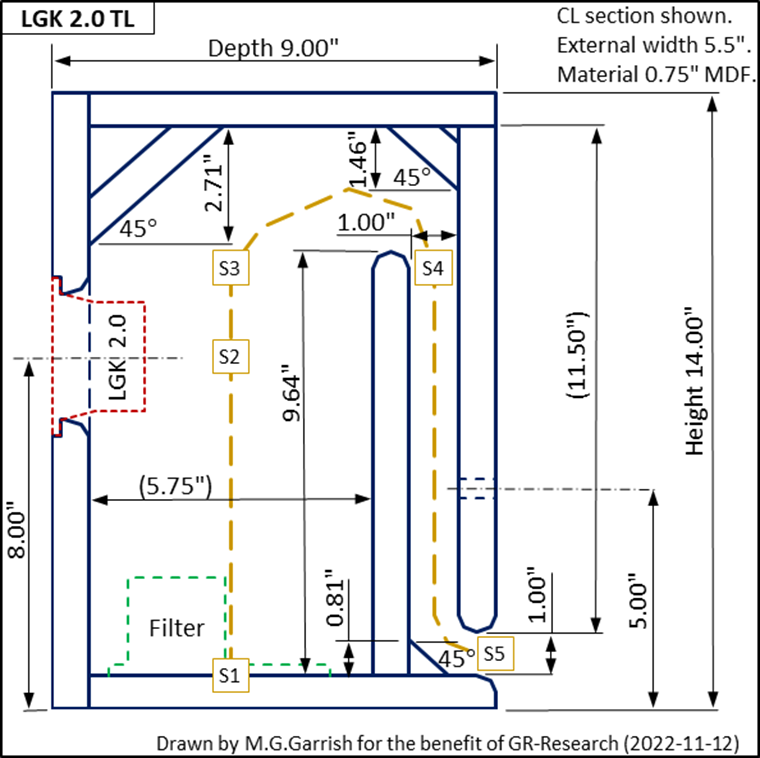

I am having to watch my pennies at the moment, but want to share what I came up with. The rough draft CL section drawing shows that the design was done in inches as I noticed the original was designed in inches. I have omitted features, like driver and tube connector machining, as those will be a straight copy from the existing LGK 2.0 design. I put dimensions to 2 decimal places, but they are not that critical. I imagine Killian will want to play with the design to suit manufacture for completed cabinets and/or kits. For BSC filter fitment I suggest putting the trap door in the base of the cabinet as there is no access from the rear. Drilling holes in the baffle for speaker cables is fine - just seal them. For the stuffing start with with 26g (~1 ounce) of acrylic fibre then adjust for smoothest base - evenly distributed right up to the location marked "S4" on the draft CL section drawing. Transmission lines are not too finicky about stuffing, which is why they are so suited to the DIY market. Please feel free to ask questions about the design process.

Danny, if you do like the LGK 2.0 TL design then I'm happy for you to offer it on your website. There does seem to be a strong audiophile following for full range transmission line speakers, and I'm pretty sure you're going to like how these sound. It would be nice if you could throw the prototypes my way if they do get tested - I'm partial to walnut veneer.

Best regards,

Mart

Martin Garrish

B.Eng, B.Sc, M.Sc.