That rotozip tool... do you like it? Any particular one? I'm going to play with the LGK drivers and need to cut some small 3.58″ holes. The good news is I have zero woodworking experience... but I do have a lathe / milling machine for making metal chips. I will either machine adapters out of aluminiumium, or make them from MDF. That rotozip tool will cut a nice, small hole in 1/2" MDF - and is the best way to do it?

Thanks for any advice.

I too have a bit of metal working experience, and started these speaker builds with only basic wood working knowledge and learned what I needed along the way. I found lot of good threads in this blog and several really good videos that learned from.

As for the rotozip tool, are you referring to this picture/discussion?

That rotozip tool is really good for doing what it was made for. That is, cutting rough holes in drywall. It was used here only to cut a a hole in the No Rez (a foam backed linoleum-like material) that was applied to the inside of the cabinet after the hole in the MDF was made. This would not make a good tool for cutting holes in MDF. It would be hand held and the hole would rough, not square to the face and not overly round, if your handiwork is anything like mine.

For woodworking hole cutting I would recommend a router with a plunge base and circle cutting template.

This is the 20v cordless Dewalt router with their plunge base. The nice thing is the ability to put a dust collection system on it. MDF dust is toxic, the the dust collection is important. Dewalt does make a corded version of this router and I am sure there are other brands that would work well for this.

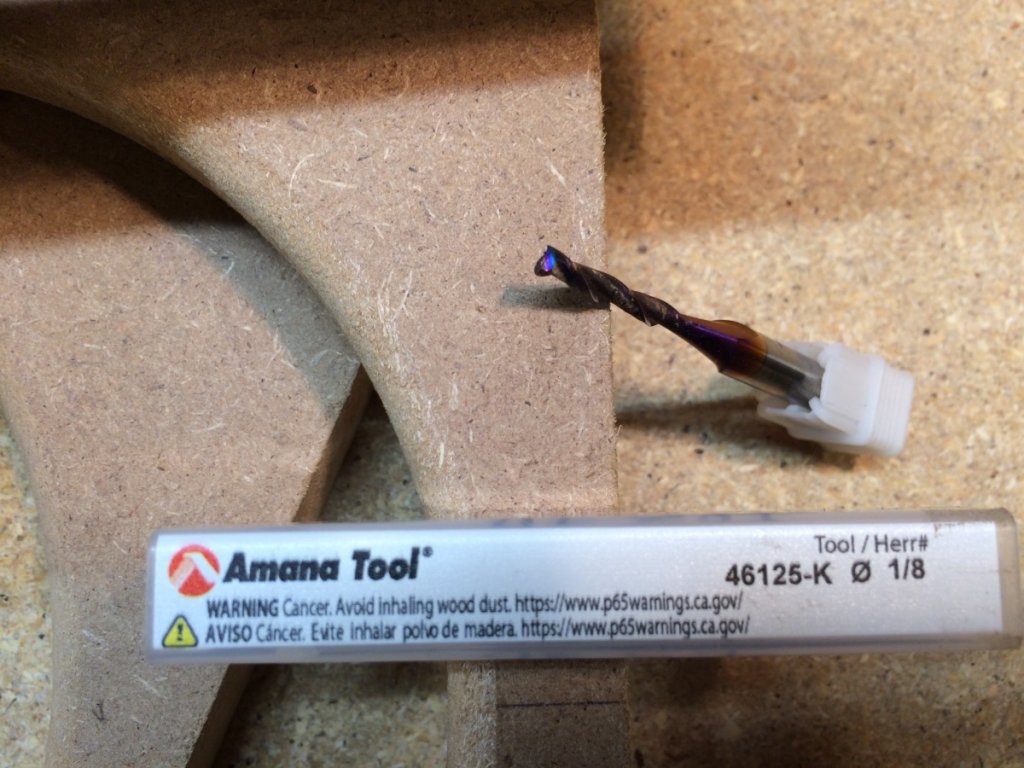

This is the cutter I use. I see no point in cutting more than necessary; the 1/8” cutter works well for this.

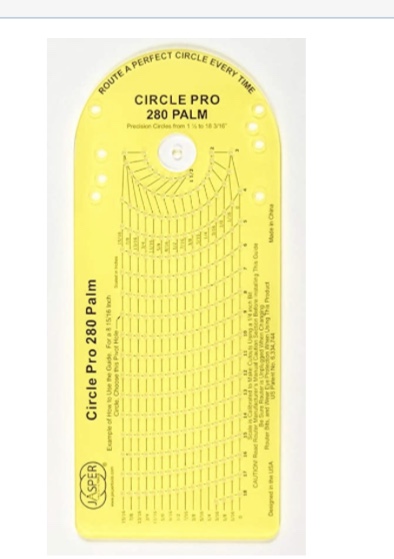

I have gotten a ton of use from this circle cutting template. This just attaches to the router base and makes perfect circles.

This is pretty much the whole setup.

You could do aluminum, but I think that for purity of sound, you would want to stay away from any metals that could introduce any kind of ringing or the like.

Not sure exactly where you are going with this, but all of Danny’s cabinets are 3/4” thick. That might be a better option than the 1/2” to get the most stiffness. Again, depending on what you are doing.

Hope that helps.

I also see in your signature that you are a chief instructor for Chin … HPDEs, something that I also dabble in (tracks here in the NE) with a couple of MINI Coopers I have. Maybe our paths will cross if I ever get up the nerve to deal with the “pass anywhere” allowance Chin has for the advanced drivers. I fear that might not go well going up through the esses at WGI…