Sorry for the absence y'all. I got a new job unexpectedly and have been in the process of moving across the country and getting up to speed in my new role. Had to put these on hold for a few months. Trying to finish up the carpentry work in the next couple of weeks here. Here's the progress so far.

First, I built a work bench, my very first foray into woodworking:

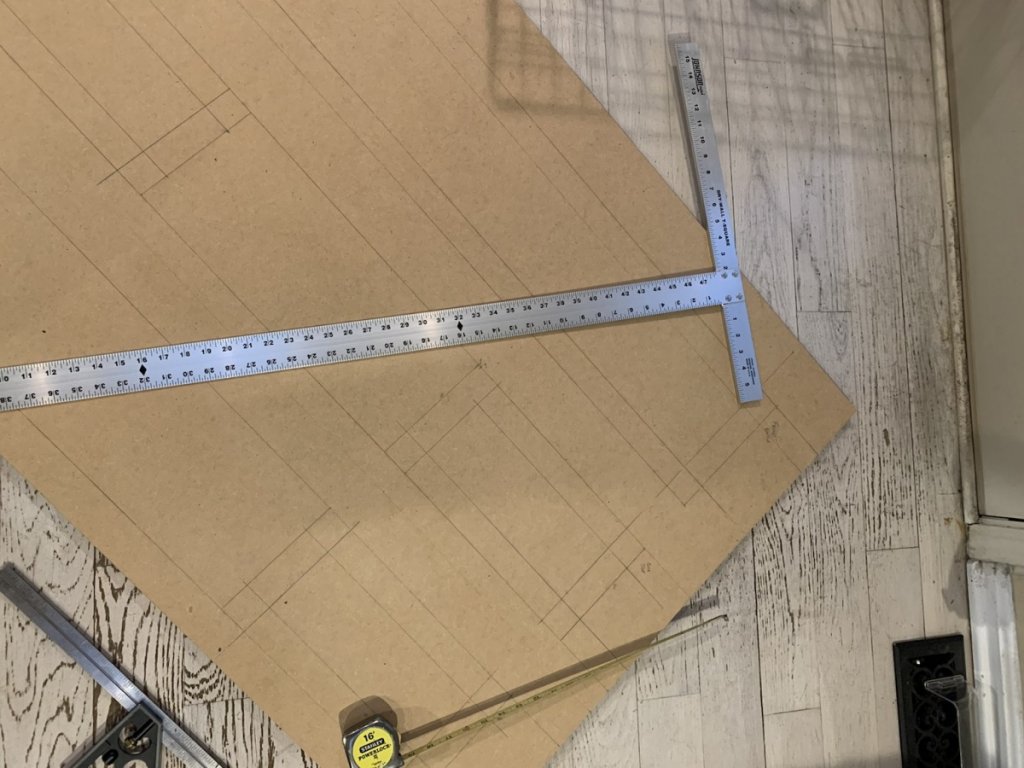

Next, I got my MDF. Three 4'x8' .75" thick boards did the trick for me. Lots of trial and error with the circular saw. Using a drywall t-square I sketched out the pieces and cut-lines:

Cut my initial pieces out using a circular saw and a clamp saw guide:

Next, the router. Never used one before, but this thing is awesome. Using a downtrim cutting bit from Whiteside and a Jasper circle, jig I made the inside braces:

For all the pieces aside from onces with angled edges, I only cut one speaker and used the router with a sprial flush trim bit to clone for the second, cutting only the rough shape first with the circular saw. This made things so much easier:

With sides and braces now cut, it was time to glue. I used Titebond original. First side was easy, making sure the second side was perfectly level with the first was a challenge. My first attempt at this I clamped a flat piece of mdf to both sides of the first side to ensure it would be level. This resulted in an ever-so-slight misalignment, but one I can deal with when I glue to the base. The second time I just clamped the two sides together and stood it up, putting pressure on the sides to make sure they were level then tightening the clamps:

For the back, I cut the top with a 10 degree angle and made sure the rest overlapped on all sides of the cabinet. I then used the flush trim bit to trim off the edges:

That's where I'm at currently. Hope to have more updates for you soon. Not sure if/how I should make the base or front baffle removable so I can get to the crossover later if I ever need to. What do you guys suggest on that?