Hi,

Do you would post some photos on the Merlin inside?

So, here's how these were made. The baffle is 1.5" thick, but there is not much bracing on the inside. Just a couple 1"x2" braces, 1 front to rear and the other side to side. There is a section that separates the bass cavity from the Esotar. There is a Stereophile review over a decade ago of the "Millennium" version of these speakers. Atkinson mentions a cabinet resonance just below the port when he measured it with his accelerometer attached there. So, I may get some No-Rez from Danny and put some there and elsewhere. My speakers were made in '99-ish. I don't think the cabinet design changed much, if any. When you look at how little bracing is in the speaker, it gives some appreciation for the pictures of the cabinets in various GR Research speakers. Still, even without a bunch of bracing, it weighs 85lbs... being a simple 2-way setup with Esotar tweeter and ScanSpeak 8545.

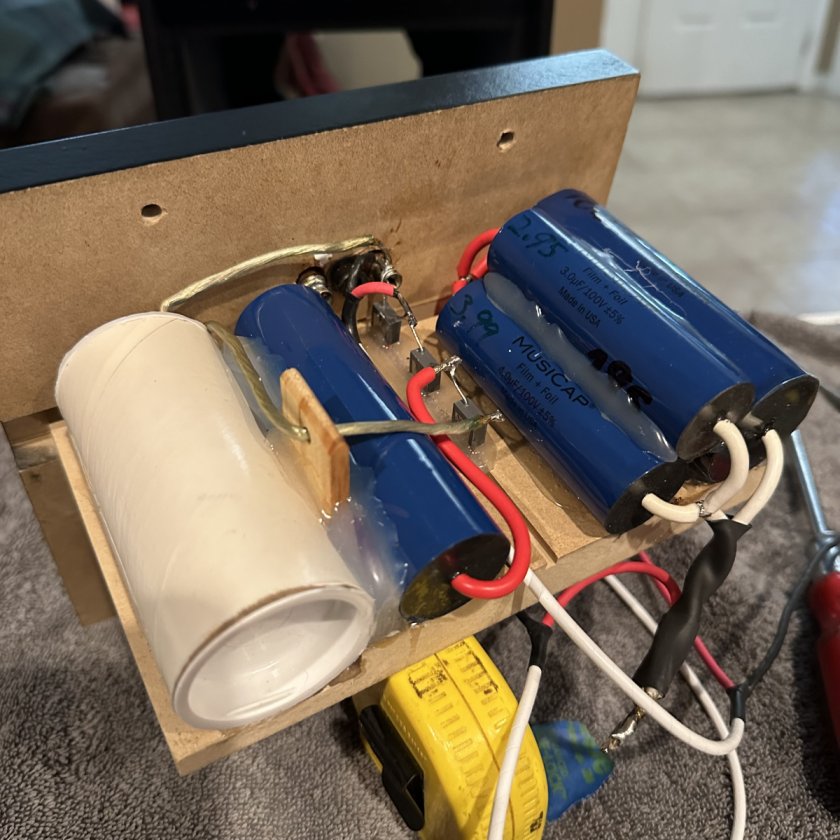

Danny measured a VSM (not my VSMs) a long time ago and sent me the measurements when they came up in conversation. I was surprised to see the measurements were not that great, as I really like this speaker. I suspect Danny was sent an early version of the speaker. The late Bobby Palkovic went thru many tweaks on this speaker... and I don't know exactly what was done. I had Bobby do one revision to the crossover and they definitely sounded fuller. His final version before he passed was the "Black Magic", and I have those crossovers to install. What is different about them versus any other version, or what Danny measured, I don't know. There is a guy who worked very closely with Bobby who performed the crossover mods (Rich Brkich) and I'm going to ask him about that.

I do have a speaker that Danny has measured directly. Using REW and a Umik microphone, I am going to take my own measurement of that speaker, unmodified, to see whether I can effectively reproduce his results. If I can do that, then I'll know I can measure properly and I am going to start making simple tweaks to each of these speakers to see whether I can make them sound even better, learn a few things, and have some fun.

I think playing with this stuff is going to help me sort thru and think about what I really want for "the next speaker..."