The X-CS is finished!

And up and running:

Overall, it is definitely worth the effort...

My overall impressions... It is tough to compare this center channel to the X-MTMs. The X-MTMs are so transparent and have such a wide range. It was even tough to tell which speakers were playing; the X-MTMs in 2 channel or the X-CS in 5 channel produced the identical location for voices. That surprised me. The speakers are well matched for that. Where the difference comes in is the range. As expected the X-CS drops off in the low end at a noticeable higher level. Voices are the same, but there is a difference in the level of sounds, other than voices, that come through... Now, I will admit, this could be a difference in the way the AV receiver divides the sounds between the channels and the fact my 2 rear speakers are pure crap...

and I was only playing broadcast TV and not an action movie DVD or the like. So, this may not be the fairest of comparisons...

If I back pedal to what I said about the center voices, the X-CS is truly up there and worthy of being paired with the X-MTMs...

Once I got past the idea of needing to perfecti the finish on the cabinets, I moved onto the soldering of the wires to the drivers and binding posts (yes, I know, tube connectors... Later dude, cables and better AV recover first), and installing the drivers and binding posts into the cabinet. The soldering went well. Actually easier than on the X-LS or X-MTM speakers... Why? I don’t know. I know how to solder. I have done it for years. Maybe I just took more care this time when I tinned the wires and posts on the drivers. I also had a higher wattage soldering iron... that could be it.

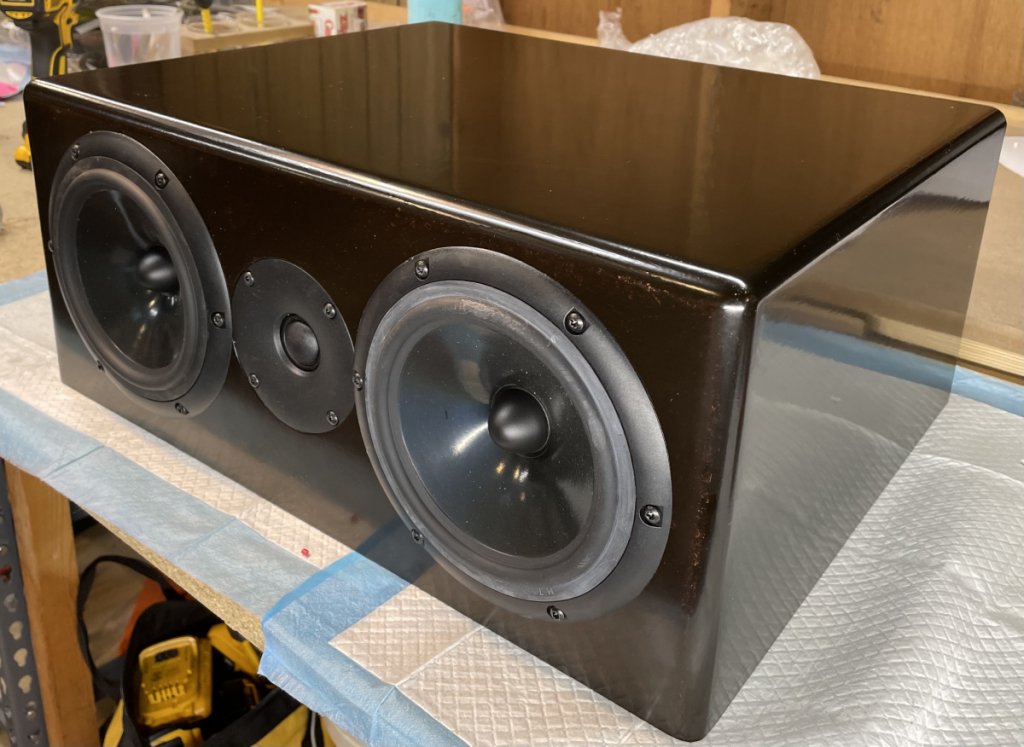

The completed speaker looks great:

The speaker will be on a glass shelf, so I added thick felt feet to the underside:

I did the same to the underside of the TV base. I figure with these there will be little chance of there being buzzing or rattling between these pieces.

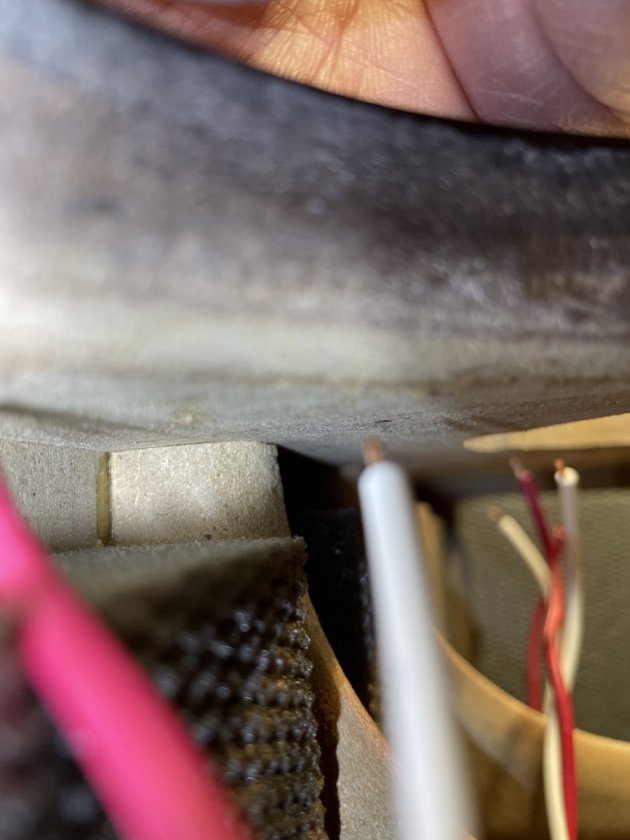

I did find I made 2 small errors when I glued on the front baffle. The first was not outlining (marking) the locations of the ends of the 2 center braces on the inside of the front baffle. As a result, the tape I used to seal one of the driver openings got stuck between the end of the brace ends and the front baffle. Not a big deal as it probably “fixed” the other error I made. That is, I forgot to put a dab of glue on the ends of those two braces... Given how close they are to the front baffle I was wondering if they would buzz as a result of missing the glue. From what I can tell, no buzzing...

Well, surely there can be no buzzing where the tape is stuck in. Lucky fix:

At least for the 2 ends of that one braces.

But, I was not so lucky with the other brace. The tape didn’t get into that area, so, hopefully, the ends are tight up against the front baffle.

After thinking about it for a bit, I figured this will likely not be an issue at all. The other thing I came up with is that I would have been better off just cutting these two braces 1/8th inch short. If they were glued, they would provide little if any support to the front, so a space shouldn’t affect the end result. A space would then make the build slightly easier with not having to deal with my 2 errors and in not having to be precise in their overall length. Something for the next time.

I hope this was an interesting adventure for everyone following... I know, I enjoyed it.

Now off to do a set of rear speakers, a set of rear speakers... X-Omni? Yes, I think so. They should do nicely in the room I have... Now, just waiting on parts...