I built a set of four speakers. When I built the boxes with Hiddensity MDF I did my normal damp rag wipe down to make sure dust / things clean before I did peel and stick of no-res

After about three months I noticed on the one tower a weird flopping noise during some lower frequency ranges. I ruled out seal issues around speaker etc.. and ended up taking speakers out and found two peices of no-res delaminated and flopping around. I did a clean with damp cloth.. even used a bit of alcohol to remove any oil . re-applied but came back again. So I used some 100% Silicon to re-adhere.

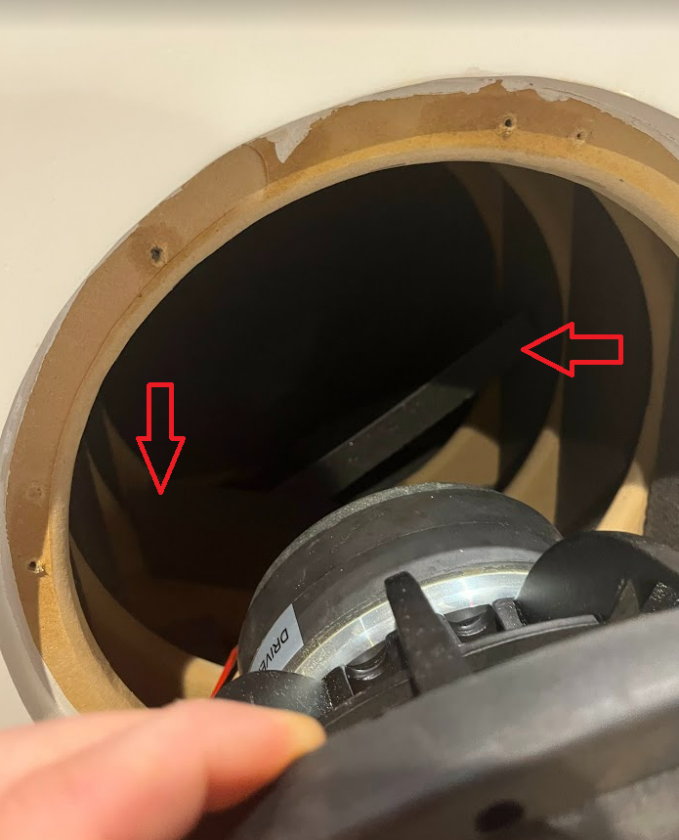

Now my Servo Sub on the one side a few months later started making a weird "flap" noise on certain note. Pull speaker out and two peices of no-res flopping around.

Questions

1) Are others having issues with long term adherance of the no-res to MDF? Maybe their is a prep step I missed of box..... or maybe one should be added.

2) How / what is best recomemnded path to repair this. Silicon is option that (knock on wood) seems to have fixed tower issue.. but before I re-seal this servo sub, would like to get other ideas. I am considering using short nails / brad nails...(mechanical) in addition to silicon.

Are others seeing this issue with No-REs?

I also tried to capture image of the back of the No-Res pads... noting the different adhesion patterning. The Lighter/highlighed sections is less sticky and to me , would denote that it "left" its sticky side on the MDF side. AKA: Those locations reflect bonding sufficient to have created a delamination of the glue to the wood higher then the plastic backing substrate. This is good IMAO. But question is .. why is it not uniform. This would seem to indicate very un-even application (user error) .. possible... but not my first goat rodeo and I try to do things well, and avoiding miss/ poor application of peel and stick was something I tried to avoid by cleaning, pressing.. wiggling.. rolling in one direction etc.. as I applied. With this stiff of a material, my guess is.. I did not do so well, and so the glue kind of needs to be a bit more "strong", but .. lets see if others can add experience to broaden base.

Thanks in advance for updates / ideas and corrections.