Nice Job  Someday I hope to make a pair myself.

Someday I hope to make a pair myself.

Thanks man. I'd have liked to have done a pair at the same time but couldn't swing the funds so doing 1 H Frame at a time. Hopefully it woun't be tooo long before I can do the 2nd .

Ok, grill frame....

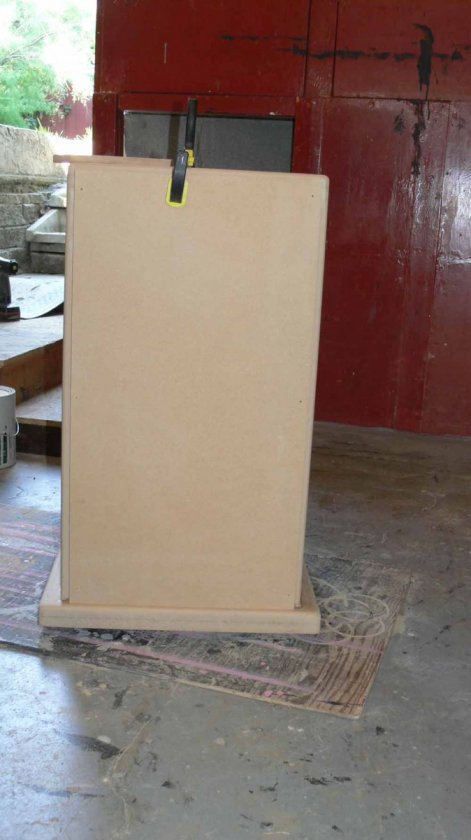

1st I cut the piece of 1/2" MDF to the size I wanted for the grill. Sized it so it would sit 1/2" insded the cabinet outer edges on the sides and top, it will site down on the base at the bottom. Once I had that cut, I marked out the 6 locations for the magnets and then used a 1/8" drill bit to drill right through each spot. With my low vision, I find doing it this way is much easier than rasfering the measurments to the cabinet, plus I can use the through holes later. Once I'm done and the magnets are epoxied in, I can just fill the little holes with either a little glue or wood filler.

Once the holes are all drilled I clamp the grill blank in place on the cabinet, spacing it equally on both sides then use the same 1/8" drill bit to mark the cabinet at each spot.

After each hole is marked on the cabinet, I remove the grill blank and proceed to drill the holes for the magnets. In this case I had planned on using 1/4 x 1/4 N52 cylinder magnets (thought I had some) but after looking closer at what I had on hand, I found I only had 3/16 x 1/4 N52's which are going to have to do. I'm sure using 12 ( 6 in cabinet, 6 in grill frame) will work fine, these little guy are surprisingly strong.

After drilling the holes in the cabinet, I epoxy the mangents in place. I usually smear a little wood filler over each one just to fill in the "edge" around each magnet. Run a piece of 120 grit over each one using a block after it drives.

Now it is on to the frame itself. I decided to leave the frame 1" wide on the edges. It's 15" wide so a 13" cut out should work great... I left the bottom frame 1.5" thick for something later. Befroe routing out the holes, Ir ounded each corner and then ran a 3/8" round over around the outside. Then I routed out the large holes

After this, it's just a matter of getting rid of the little pieces left over in the middle. Time to put those little 1/8" holes I drilled all the way through to use again. I use them to run a #6 x 1" wood screw through and attach a guide for a flush trim bit to cut out the little excess pieces. This works well as long as you aren't distracted and thinking about other things

Note the little blooper in the lower left corner, don't ask what I was dong cuz I can't tell you. At least it is only a grill frame and some MDF saw dust mixed with some glue easily filled it in.

I wanted to finish this up this eve but I'm going to let that patch cure overnigh before I run a 2/8" rond over around the inner edge of the frame

-jay