Not sure if this is the appropriate forum, but the speaker kit was C&C...

Hello,

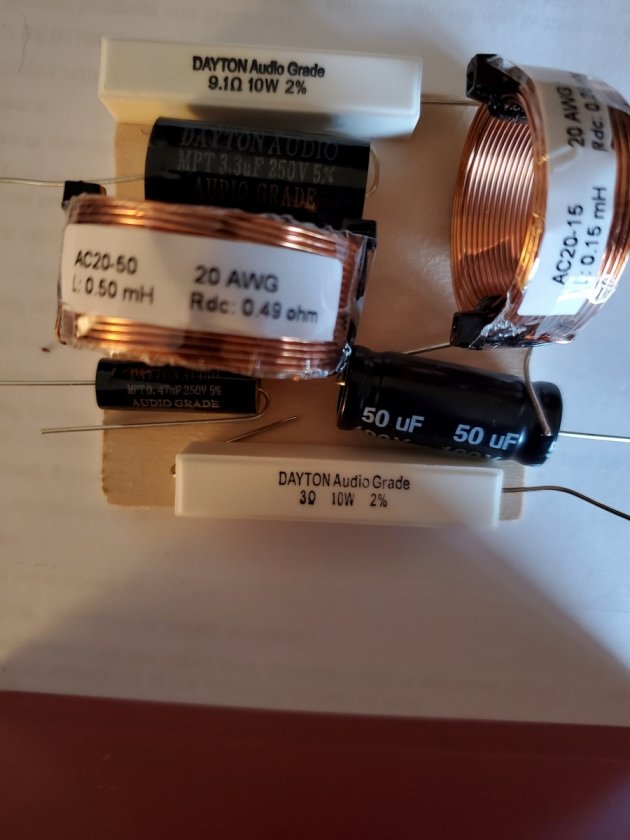

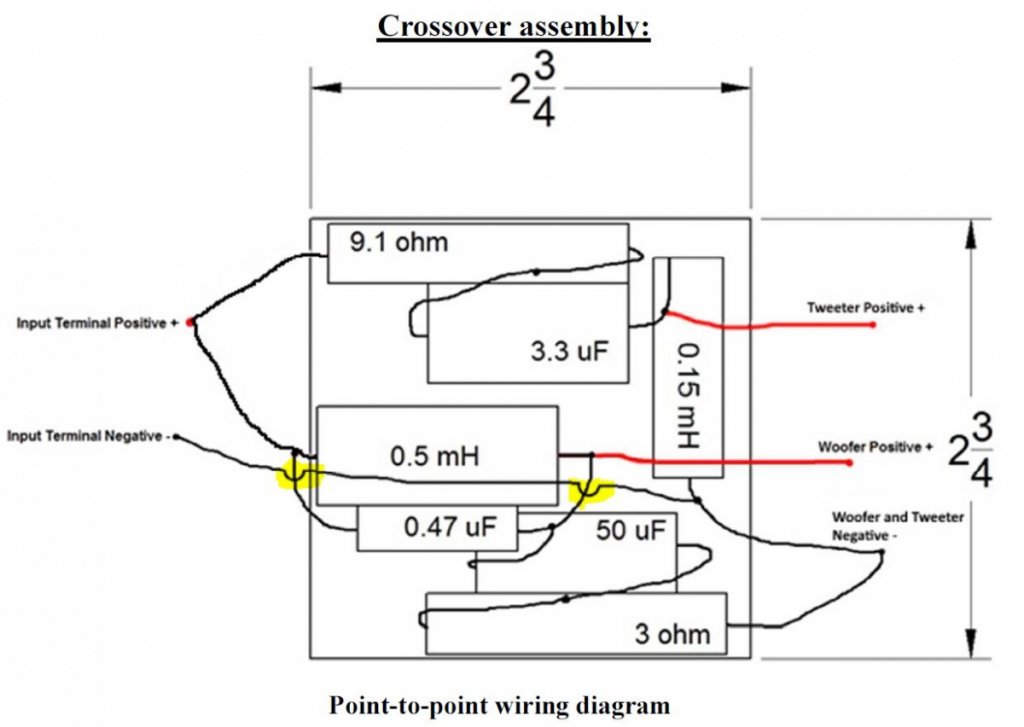

I am building my first crossover as part of the Parts Express Passive Aggressive speaker kit. I have a couple of questions if I may (sorry if they are dumb questions):

1) Am I correct that the the yellow highlighted wire bends in the diagram denote that the wire is just passing another wire there and that they are NOT to be connected?

2) Should I hot glue the components down to the board before soldering the component leads and wiring?

3) Is it okay if the components touch each other? Not the leads (obviously), I have sheaths to cover those, but if the components end up touching is this okay? The crossover board is only 2.75" x 2.75", these are desktop speakers.

Thank you for your help and guidance!