I really haven't been in the mood to do anything with the eyesore in my living room called the Wedgie. It is one the best speakers

I have ever heard but it suffered from a serious lack of output, which I found out had a lot to do with the equipment I was using.

I was using a passive preamp which is not the best setup for running a power amp and plate amp together. I recently purchased a

Schiit Saga buffered preamp and it made quite a difference in the 3-8's output. So I decided to do cosmetic changes to the Wedgies.

Original Wedgies

The first thing I had to correct was that ugly gap between top and base due to the Herbies Big Dots. I routed holes 3/16" deep for

the Big Dots to go in so now the top is only about 1/16" above the base. Then I ran a 45 deg chamfer around the top of the base

to provide a nicer transition from the base to Wedgie than the 3/8" roundover provided.

I removed all the drivers from the Wedgies to measure the top section. I was going to rebuild the top section but I just didn't have

enough veneer left over from the base. I have never bought the idea that the Wedgie was too hard for the average woodworker to

make. When I measured it all out I found out I was right. All this about being too hard to make and having a special CNC waveguide

was a bunch of BS. I went out to the garage and made a Wedgie front baffle in about 3 hours.I was kind of pissed knowing how long we

had to wait for the flat pack to be made.

I put a piece of veneer on the Wedgie top keeping the grain pattern matching the base.

I have always wanted to see what Rustoleum Stone Creations looked liked, and it seemed perfect for people like me with no talent

for painting. I loved the results.I painted the rest of the Wedgie, the top and front panel of the base with black granite.

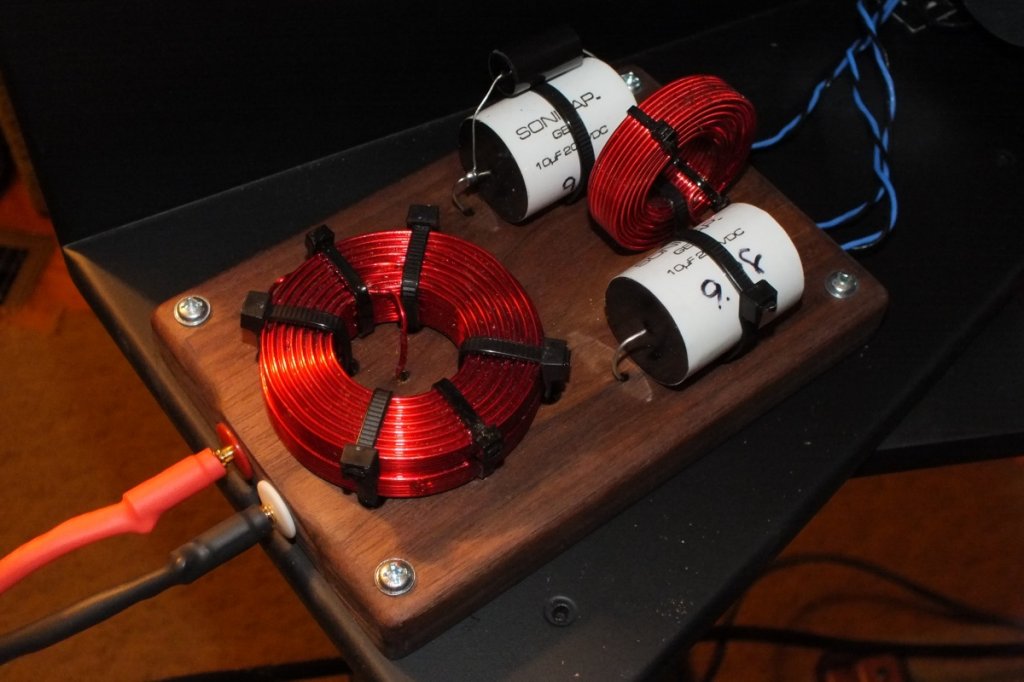

Since the crossover is out in the open I wanted to make it look a little nicer, so i borrowed some ideas from other people.

This the original crossover

On the original all the wiring and solder joints were in a cut out area under the top.

I did some upgrading to the components which took the Wedgie to a whole new level but physically they are quite a bit bigger

than the stock caps and coils. I still wanted to run the wiring underneath but I made recesses in the solid Rosewood to get the

height lower.

I cut out tops and sides for the coils.

What it looks like on the Wedgie. They will be screwed on from the bottom.

In about a week I can started rubbing out the lacquer on the top section to match the base.