Thanks, Mike! That's a challenge about the amps... in my living room, in order for the rig to be far enough from the front wall I'd need to be able to walk behind the speakers and not kill myself on an amp box. Hmmm. In the acoustical domain of the human brain the time latency of a few feet of electrical cable should be irrelevant, so I'm curious what the deal is.

I also appreciate your trying to help me out with the MTM dimensions.

At the same time--Danny--is it too much to ask for you to update your new site with the basics of the products you're selling? A year ago the excuse was that the new site was coming. Now it's here and a DIY-inclined person still can't find much. Scraping Audiocircle is neither efficient nor sufficient.

Concrete cabinets? I thought you wanted less bulk

As a matter of fact, I

do want less bulk. And I think it should be possible. In my opinion, gluing flat panels of MDF together isn't necessarily an advantaged choice for containing high pressure radiative sound waves in a non-resonant fashion, much less doing so in a compact visual footprint. That's my take and I'm sticking with it... unless of course my other ideas bomb.

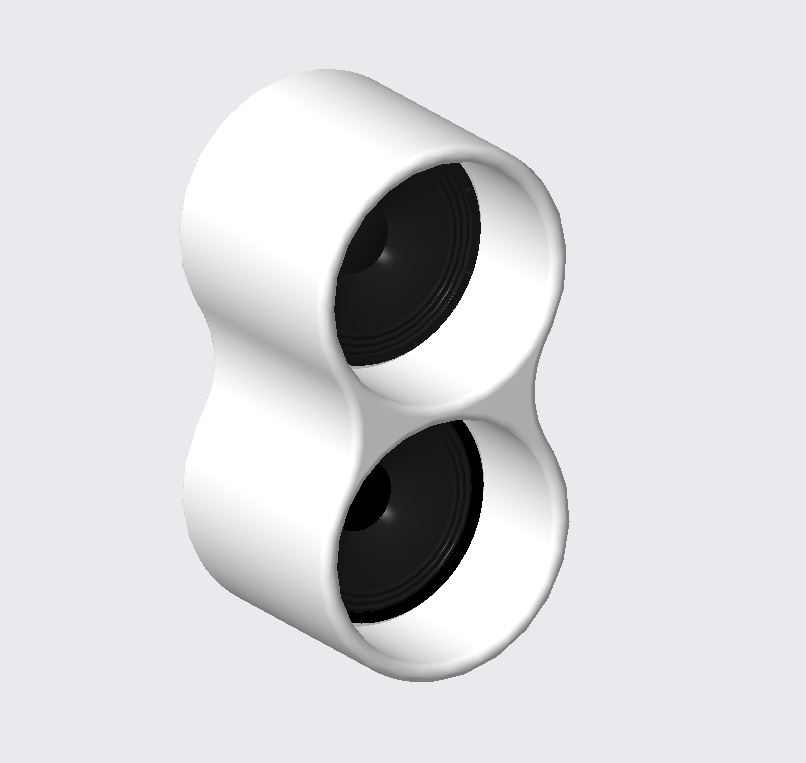

I've mostly been sketching on paper in odd moments between busy work and family moments, but I did quickly model up one of the many potential directions I'm considering for what could be called the sub chamber(s). As shown, this has 1" thick walls of countertop or similar/better grade concrete. Naturally there'd be stabilizing feet and the mid/tweeter section above it. It's just a simple version to study proportions, 15" outer tube diameter and the aforementioned 14" deep. It's not the right driver, I downloaded it from a kind individual on GrabCAD. Building a mold for one of these would take some doing for a concrete newbie, but once figured out it should be pretty easy to make the second sub section.

I have other ideas with separate front/back shells that in effect sandwich the driver--meaning, conceivably as low as 13.5" outer diameter--as well as deaggregating each individual sub zone as its own tubularish volume with a modular stacking potential to go 1-2 high as a FR speaker or 2-4 as separate sub towers, probably at the cost of some height efficiency. Ah, if only this fun play were my actual occupation.

Assuming that it's stiff enough etc, are there any acoustic reasons why the fundamental geometry of this direction would run into problems?