I've been thinking about sometime similar, albeit for different reasons.

My hypothesis is that there's a market for a kit that facilities a much more "professional" finish with far fewer woodworking skills. As soon as you start talking about clamps...I'm out. There's a 0% chance I could obtain a paint finish I'd be proud of as well.

With a stacked approach (particularly with 3/4" baltic birch ply), not only could you offer a glue-n-screw kit, but it would eschew the traditional "box" speaker look. 1" thick all the way around. Dowel holes to ensure alignment. Pilot drill holes to stagger the screws. Side-mount the speaker binding posts. Offer the baffle pre-finished. Sand, stain, poly the baltic birch ply. Plus, a different number of stackers could facilitate different speaker configurations.

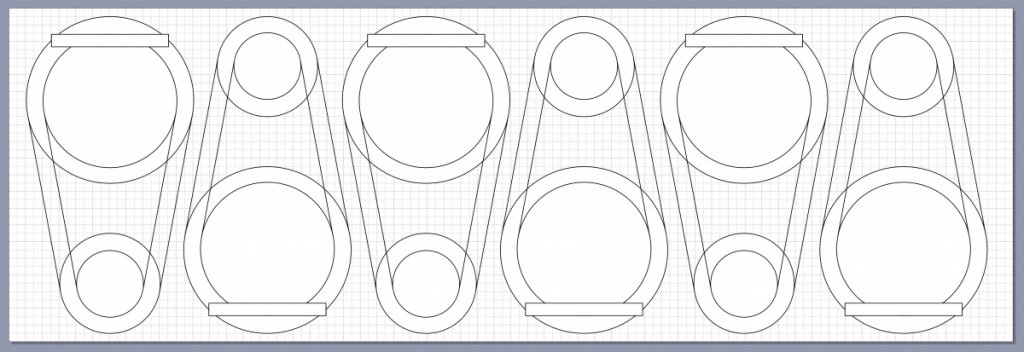

The image was modeled 19" front-to-back, with the front a 10" circle, and the rear a 6" circle. It would be easy to augment the design with a bottom-mounted "mini-sub", a side mounted plate-amp and a side mounted 8" mini-sub (or 2) - both as as a stand for the studio monitor. For the monitor, the from of the 10" circle would be notched to allow the inset of the front baffle (simply glued and "clamped" by the weight of the cabinet when laying face-down).

I know Danny offered baltic birch ribs many years ago. More access to partners with CNC machinery make make this approach more doable. No, this approach isn't cheap, but it would produce some cool finished speakers.