Has anybody tried using batteries for the power supply?

Funny you should mention it. This question of performance on battery has been burning a hole in my curiosity pocket for a while now. Especially since KernelBob went out and bought a big honk'n marine grade battery to try this on his LDR1B.

Yesterday I went out and bought a 10 AHr 12 V battery and have had it running on a Tortuga V2.1 board for the past 24 hours while turned on with dual displays. It went from 12.56 to 12.15 volts over that time period so plenty of capacity relative to load. Tied to a recharge circuit my guess is you could listen to music nonstop for a couple of days before you'd need to kick in recharge. That size battery fits inside the same enclosure as the LDR1B or LDR3.V2.

Today I spent some time taking measurements of the command signal to an LDR under various power supply scenarios. While not exhaustive or definitive I think the following findings are valid:

1) Most of the noise/hash in the control signals to the LDRs is a combination of the 5 V switch mode DC converter on the controller board plus the microcontroller. The DC converter runs somewhere above 100khz and the microcontroller runs at 4 MHz. The net of this is vey roughly +/- 10 millivolt noise way outside the audio band.

2) I saw no change in this whether I powered the board from a 12 V switch mode supply or from the 12 V battery. Keep in mind that the board uses both the raw 12 V supply as well as 5 V from an on board switch mode regular.

3) Next I removed the pricey on board 5 V DC switch mode regulator which has really good specs BTW and replaced it with a cheap (25 cent) LM7805 linear regulator and then ran the board off the battery. This cut the high frequency noise/hash by 50% to 5 millivolts. I suspect that the reduction was due to the elimination of the switch mode regulators switching noise up in the 100's of kHz.

All fine and good but did the battery plus cheap linear regulator help the performance? Honestly, I don't know. It sure sounded nice but then again....it always sounds nice!

Then I ran autocal with the battery/cheap linear regulator to see if anything changed with the reduced high frequency noise. It DID! Autocal ran smoother and faster. This was with the stock autocal op amp and not the upgrade. Autocal being a closed loop instrumentation circuit this makes general sense since signal noise will impact performance.

Too early to draw definitive conclusions but this suggests the unit would be happier with pure DC supply and no switch mode noise. Audible? Too soon to say.

__________

Addendum: 6.22.15

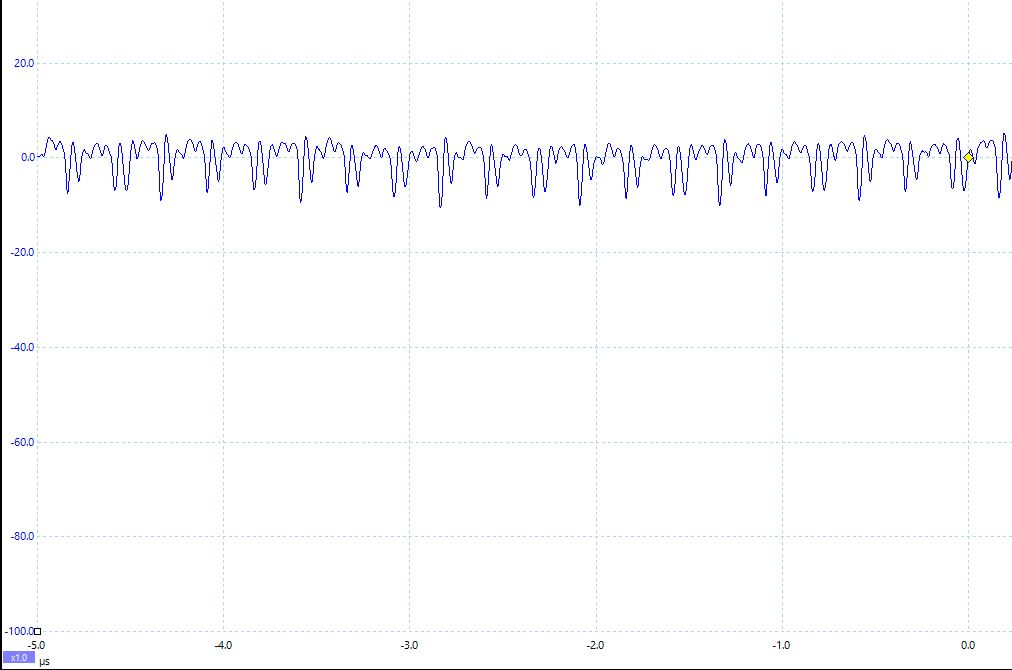

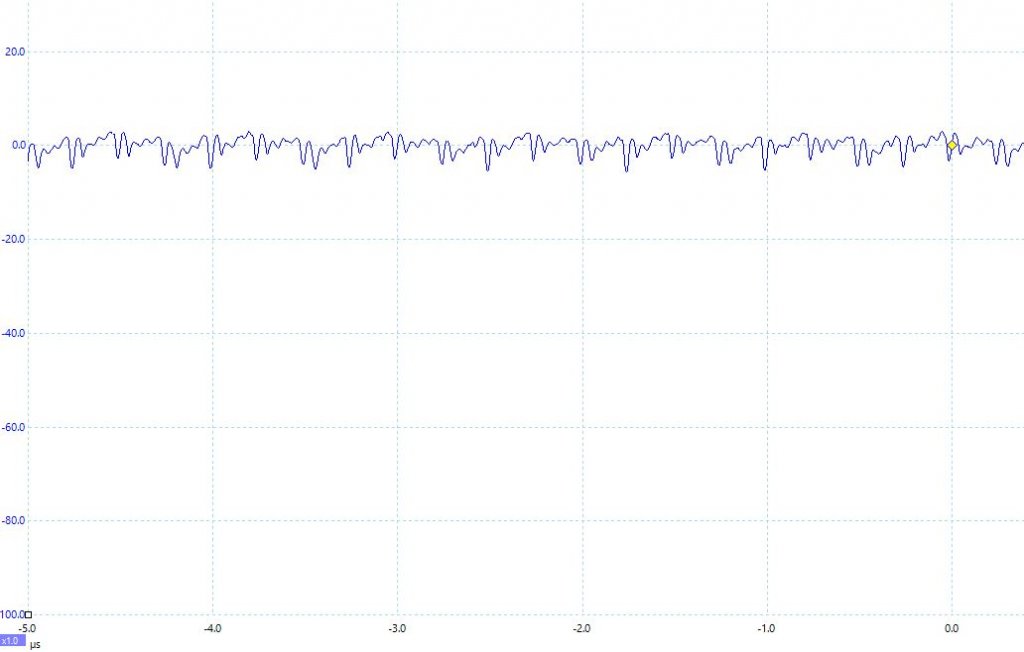

I added the pics below showing the change in the control signal noise. The first one is the "Before" which is with our own 12 VDC supply and the stock 5 VDC regulator on the board. The second graph shows the "After" when I replaced the stock 5V switching regulator with a cheap LM7805 linear regulator and powered the board with a 12 VDC battery.

The scale on the left is in millivolts and the time scale is in microseconds so each major tic is 1 MHZ. This high frequency noise is no doubt induced by the microcontroller running at 4 MHZ effective with a 16 MHZ crystal.

There's noise that matters and then there's just noise. Arguably, this noise is so far out of the audible range as to be irrelevant. Plus in order for this to be "heard" by the audio side of the LDRs, the LDR photoresistors would have to have a comparable bandwidth which they definitely do not. The reaction time of LDRs to changes in LED current/brightness is a few millisconds and not microseconds. Said differently, the LDRs filter out this noise.