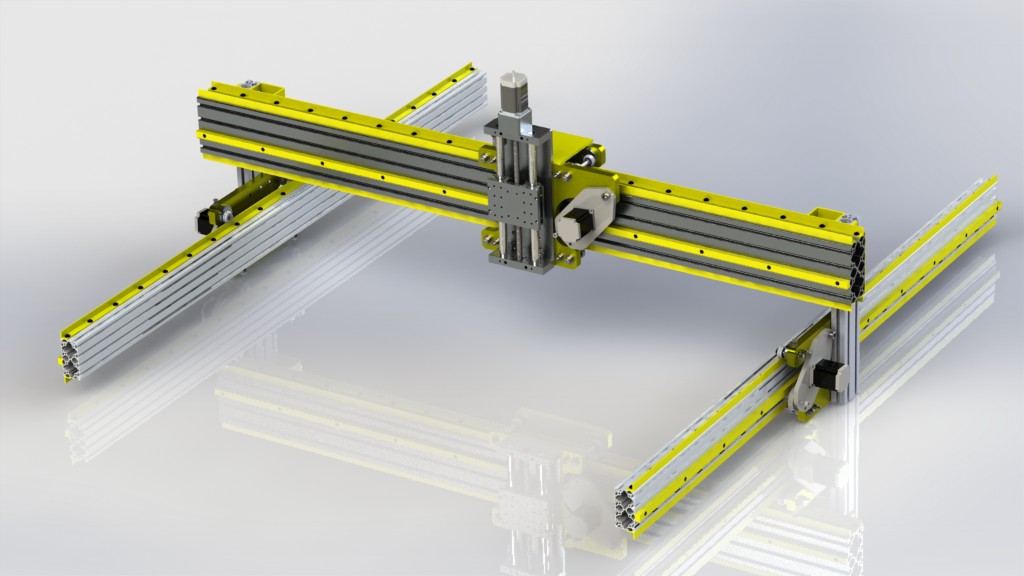

I thought I'd share some of the work we've been doing for the past few months. It's related to our work in audio in that we've been putting together equipment that will allow us to manufacture our own enclosures. A key part of that will be our CNC router/mill. It's a large format machine capable of handling at least 4' x 4' stock material. While it's not designed to mill steel, it can handle aluminum, plastics and wood. We'll be using this to mill our aluminum enclosure parts. And its been a DIY project from beginning to end.

This first pic is a nice 3D rendering of the overall design.

And as with most major projects you start at the bottom and work your way up. Here we have the bottom of the base shown upside down. Since this beast was going to weigh quite a bit, wheels were a must. And lots of wire brads & glue. More to follow later.